Automatic concentrated sulfuric acid dehydrating tower

A concentrated sulfuric acid and dehydration tower technology, applied in the chemical industry, can solve the problems of increasing operator risk, corrosion, sulfuric acid deterioration, etc., and achieve the effect of increasing water absorption efficiency and expanding water absorption reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

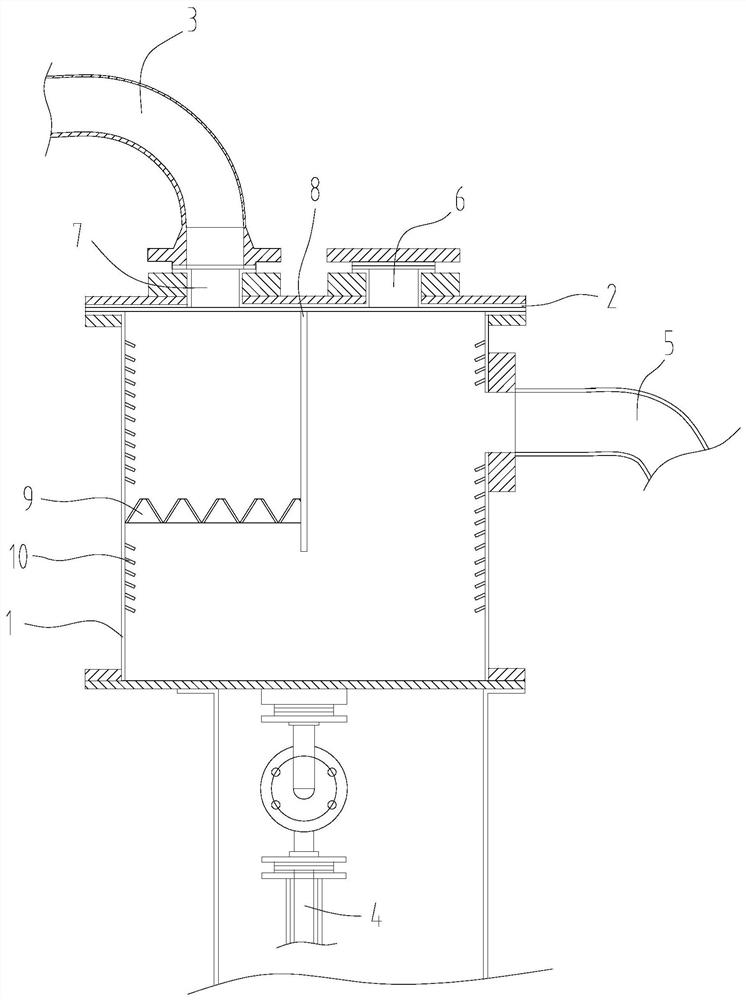

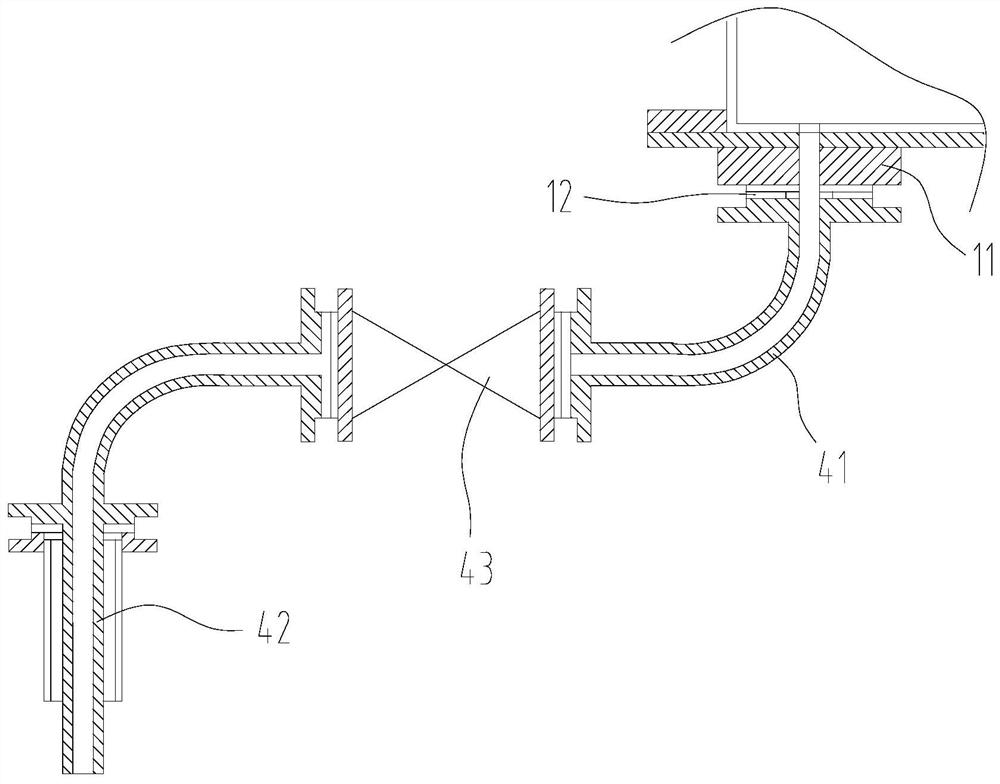

[0021] Embodiment one, such as figure 1 As shown, the structure of the present invention includes a cylindrical tower body 1, a top cover 2 is fixed on the top of the tower body 1, and an air inlet 7 is opened on the top cover 2, and the air inlet 7 is connected with the outside air through an elbow 3, and one end of the elbow 3 is It is fixed on the top of the tower body 1, and is used to input air into the tower body 1. The tower body 1 is provided with an acid inlet, and the acid inlet is connected with an acid inlet pipe 4. One end of the acid inlet pipe 4 is fixed at the bottom of the tower body 1, and the other is One end is connected to the concentrated sulfuric acid storage tank. There is an acid outlet on the side wall of the tower body 1. An acid outlet pipe 5 is connected to the acid outlet. One end of the acid outlet pipe 5 is fixed at the acid outlet, and the other end is connected to the concentrated sulfuric acid storage tank. body.

[0022] In this example, if...

Embodiment 2

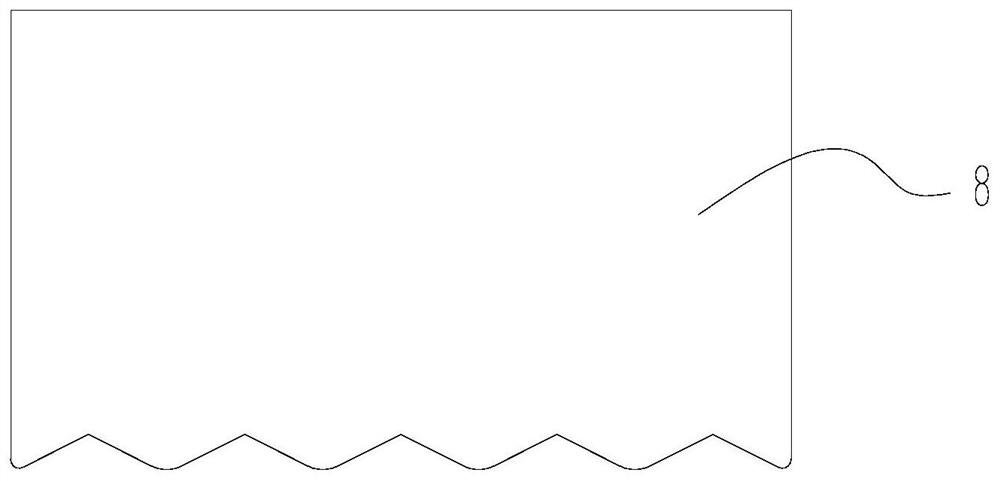

[0031] Embodiment two, such as Figure 6 As shown, the convex plates 107 can be distributed in a staggered manner, that is, each row or column is distributed at a staggered interval. The purpose of this design is that the sulfuric acid liquid can adhere to the convex plate 10 to the greatest extent, increasing the accumulation area of the sulfuric acid liquid, and at the same time, the liquid falls back The path becomes shorter, so that the liquid quickly falls back to the bottom of the tower body 1 and the raised plates 10 do not interfere with each other, which facilitates the full reaction of sulfuric acid and air. All the other contents are the same as in Embodiment 1.

[0032] What needs to be explained here is that the acid inlet, acid outlet and air intake are all realized by the pump, and the specific model and working principle will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com