Upgrading device for increasing oxygen-containing functional groups of activated carbon

A technology of activated carbon and functional groups, applied in water/sludge/sewage treatment, water pollutants, adsorbed water/sewage treatment, etc., can solve problems such as high energy consumption and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

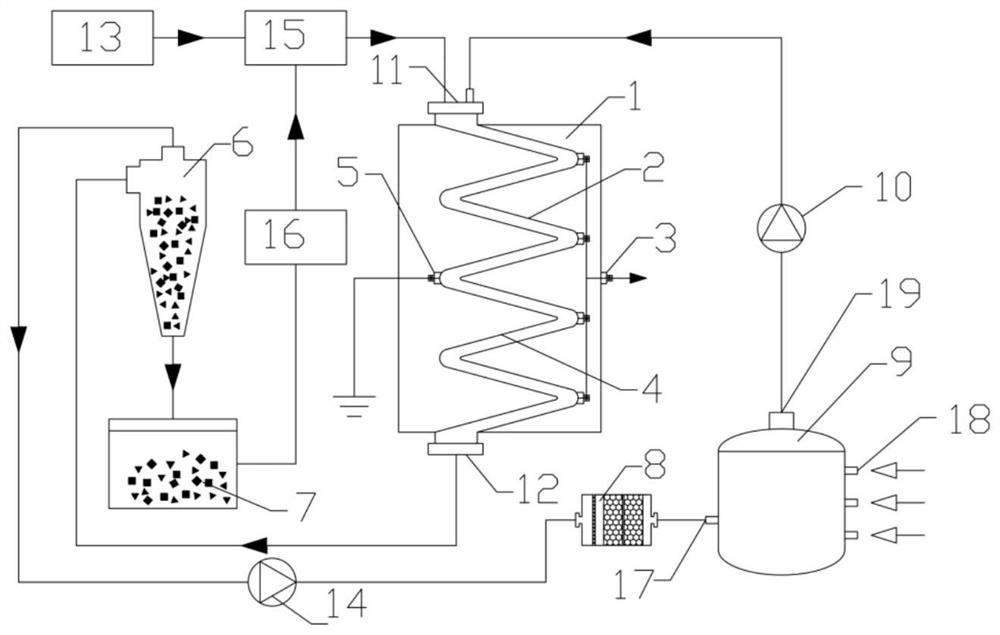

[0014] Such as figure 1 As shown, the upgrading device for adding oxygen-containing functional groups to activated carbon includes a plasma reaction system and an exhaust gas recirculation system. The plasma reaction system includes an insulating box 1 and a high-voltage electrode plate 2 and a grounding electrode plate arranged in the insulating box 1. 4. The high-voltage electrode plate 2 and the grounding electrode plate 4 are arranged parallel to each other. The high-voltage electrode plate 2 is connected to the high-voltage power supply through the high-voltage terminal 3. The grounding electrode plate 4 is grounded through the ground terminal 5. The insulating box 1 is provided with a feed Port 11 and discharge port 12, feed port 11 is connected with feeder 15, discharge port 12 links to each other with cyclone separator 6, and cyclone separator 6 discharging end is connected with activated carbon collection box 7, and also on activated carbon collection box 7 A return b...

Embodiment 2

[0019] The difference between this example and Example 1 is: the discharge voltage is 50kv, the discharge frequency is 10kHz, the input power is 60W, and the phenol adsorption capacity of the obtained activated carbon is 136.6mg / g.

Embodiment 3

[0021] The difference between this example and Example 1 is: the discharge voltage is 50kv, the discharge frequency is 10kHz, the input power is 60W, the treatment time is 15min, and the phenol adsorption capacity of the obtained activated carbon is 146.5mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap