Collection box and liquid supply device

A collection box and liquid supply technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem of low chip cleaning efficiency, improve chip collection and cleaning efficiency, and solve chip cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

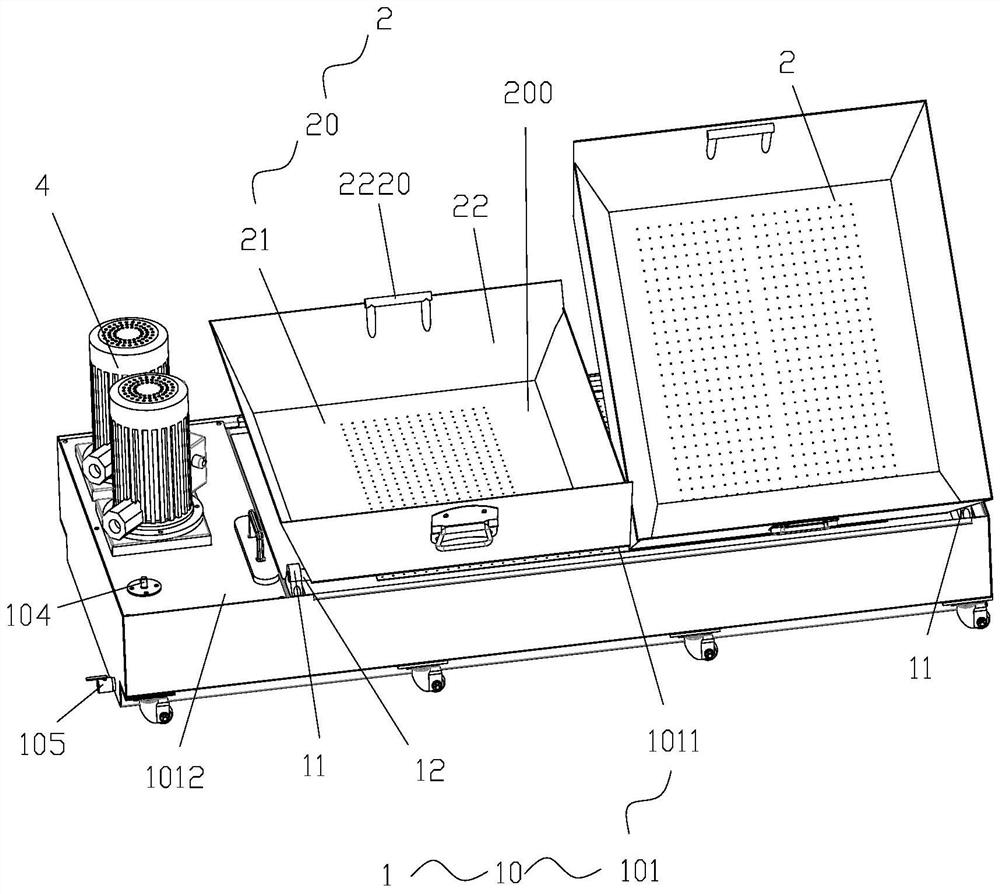

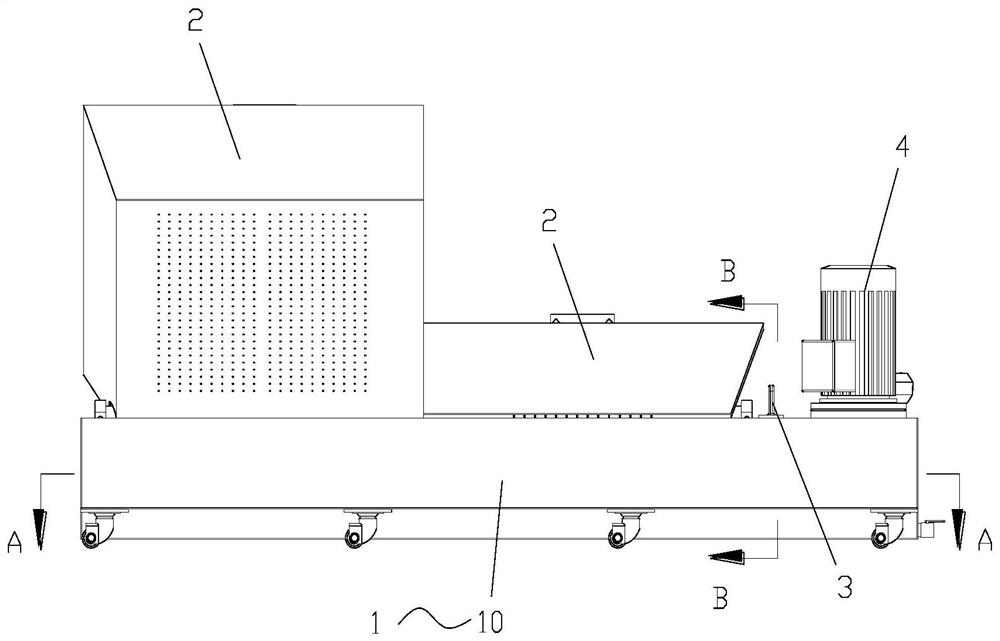

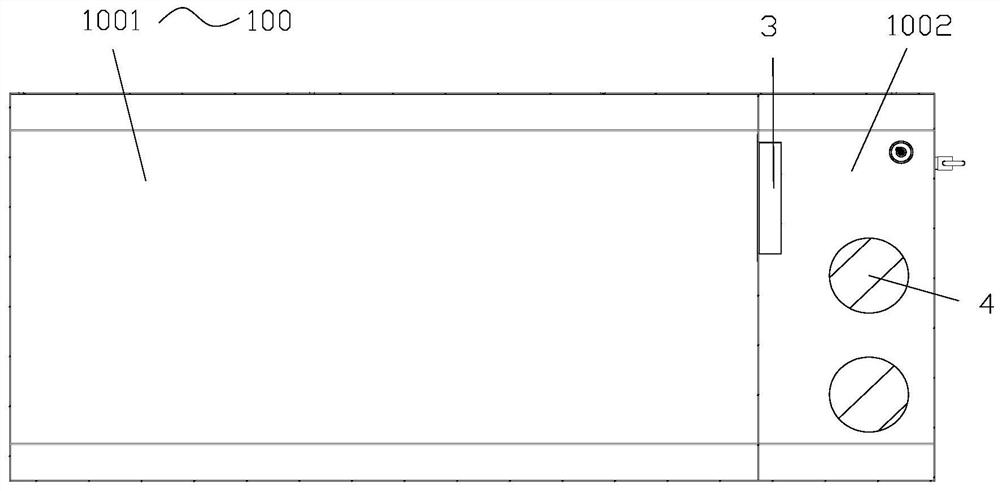

[0033] like Figure 1 to Figure 9 As shown, the present invention provides a collection box, comprising: a box body 20, the box body 20 has an accommodating chamber 200 and an opening communicated with the accommodating chamber 200; A plurality of first filter holes 210 are provided on it; wherein, the box body 20 has a rotating part 23 for rotatably connecting with the supporting platform 101 , so as to dump the substances in the accommodating chamber 200 by turning the box body 20 .

[0034] The collection box rotatably connected to the support platform 101 provided by the present invention is used for filtering, collecting chips and allowing the cutting fluid to flow to the bottom of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com