Embossing mechanism facilitating adjustment of grain depth and shallowness for tissue production

A technology of depth and texture, which is applied in the field of paper towel production, can solve the problems of troublesome adjustment, non-adjustable distance, and inability to change the depth of embossed pattern of paper towels, etc., so as to achieve the effect of convenient operation and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

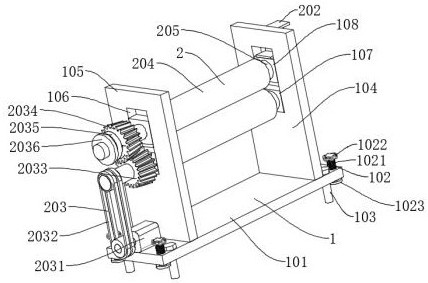

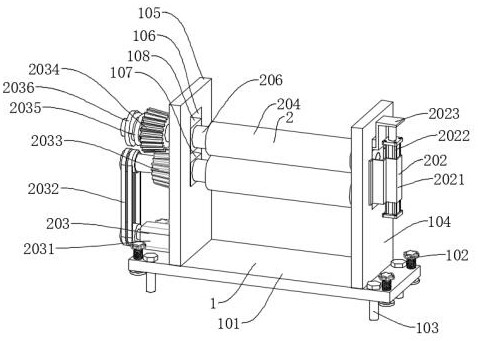

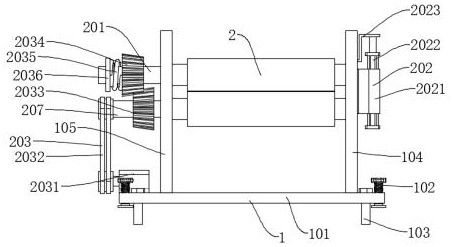

[0032] Such as Figure 1-7As shown, an embossing mechanism for the production of paper towels that is convenient for adjusting the depth of lines includes a support assembly 1 and a printing assembly 2. The support assembly 1 includes a bottom plate 101, adjustment feet 102, mounting bolts 103, a right vertical plate 104, a left Riser 105, chute 106, fixed block 107, sliding block 108, bottom plate 101 top are welded with right riser 104 and left riser 105, right riser 104 and left riser 105 are oppositely set, right riser 104 and left stand The inner side of the plate 105 is provided with a chute 106, the inner bottom of the two chute 106 is connected with a fixed block 107 by a bolt, the inner side of the two chute 106 is slidably connected with a sliding block 108, and the corners of the bottom plate 101 are provided with mounting holes and Threaded hole, the threaded hole is located outside the mounting hole, the mounting bolt 103 passes through the mounting hole, the adju...

Embodiment 2

[0035] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the adjustment assembly 202 includes a threaded sleeve 20201, an adjustment screw 20202, a fixed plate 20203, and a connecting plate 2023. One end of the connecting plate 2023 is connected to the right vertical plate 104 by bolts. On the top of the sliding block 108, the end of the connecting plate 2023 away from the right vertical plate 104 is interference-fitted with a threaded sleeve 20201, and the lower end of the adjustment screw 20202 passes through the threaded sleeve 20201 and extends to the inside of the fixed plate 20203, and passes through the bearing with the fixed plate 20203 Connection, the adjustment screw 20202 is threadedly connected with the threaded sleeve 20201, so that the setting can be made by rotating the adjustment screw 20202, the adjustment screw 20202 drives the screw sleeve 20201 to lift, and then drives the connecting plate 2023 to lift, and the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com