Dual-flow adjusting bottle cap

A dual-flow, bottle cap technology, applied in the field of bottle caps of containers, can solve the problems of inconvenience, time-consuming, waste, and small aperture dumping, etc., and achieve the effect of convenient switching, convenient operation, and meeting the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation methods and specific operation processes are given, but the protection scope of the present invention is not limited to the following embodiments.

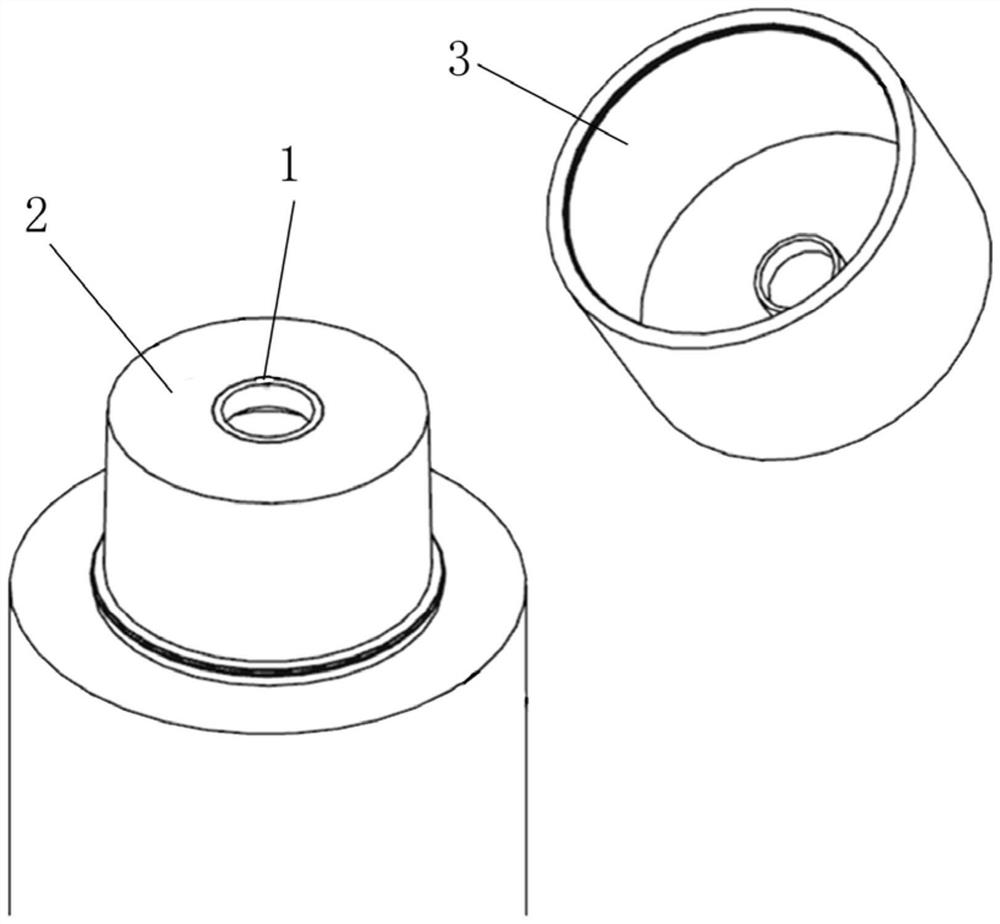

[0028] Such as figure 1 As shown, this embodiment provides a double-flow regulating bottle cap, including an outer cap 3, a middle cap 2, and an inner cap 1. The inner cap 1 can be matched with various types of solution bottles, and the middle cap 2 is used to switch the flow rate. The outer cap 3 can cover the bottle body and realize sealing with the inner cap 1 . Its specific development is as follows.

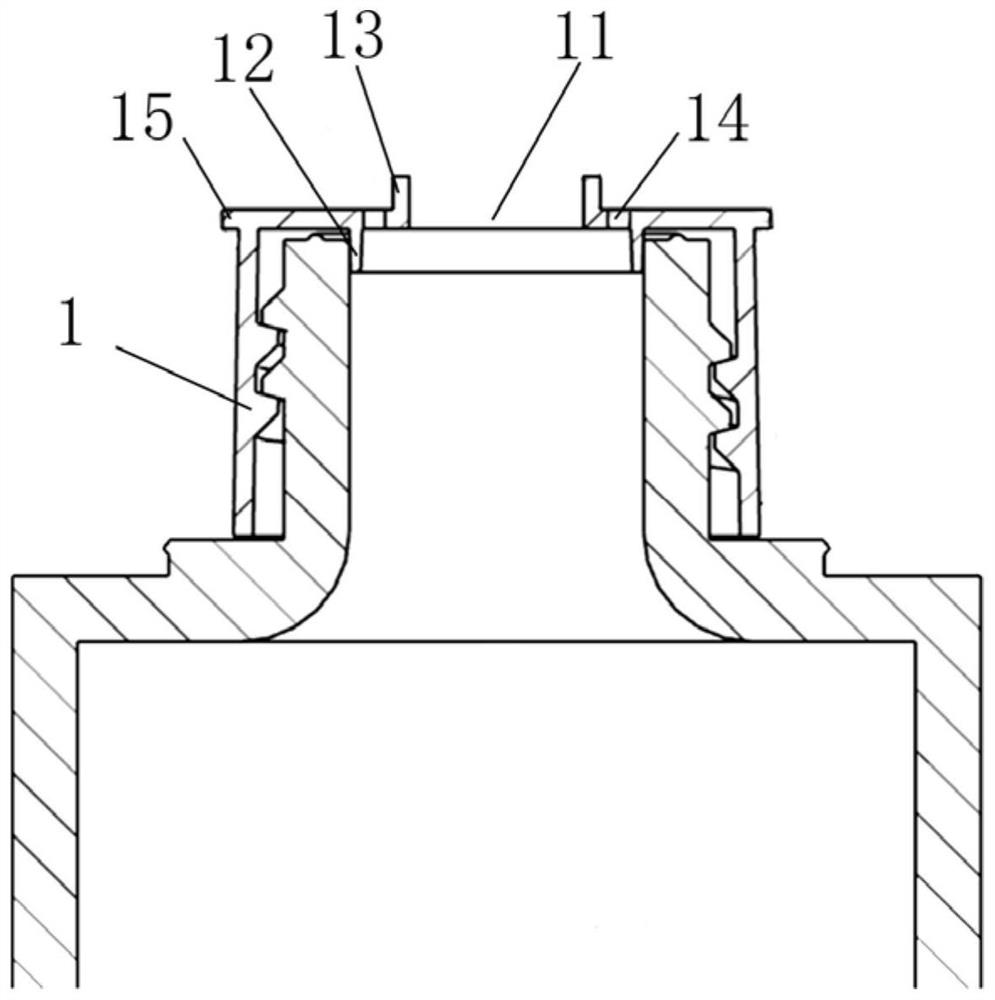

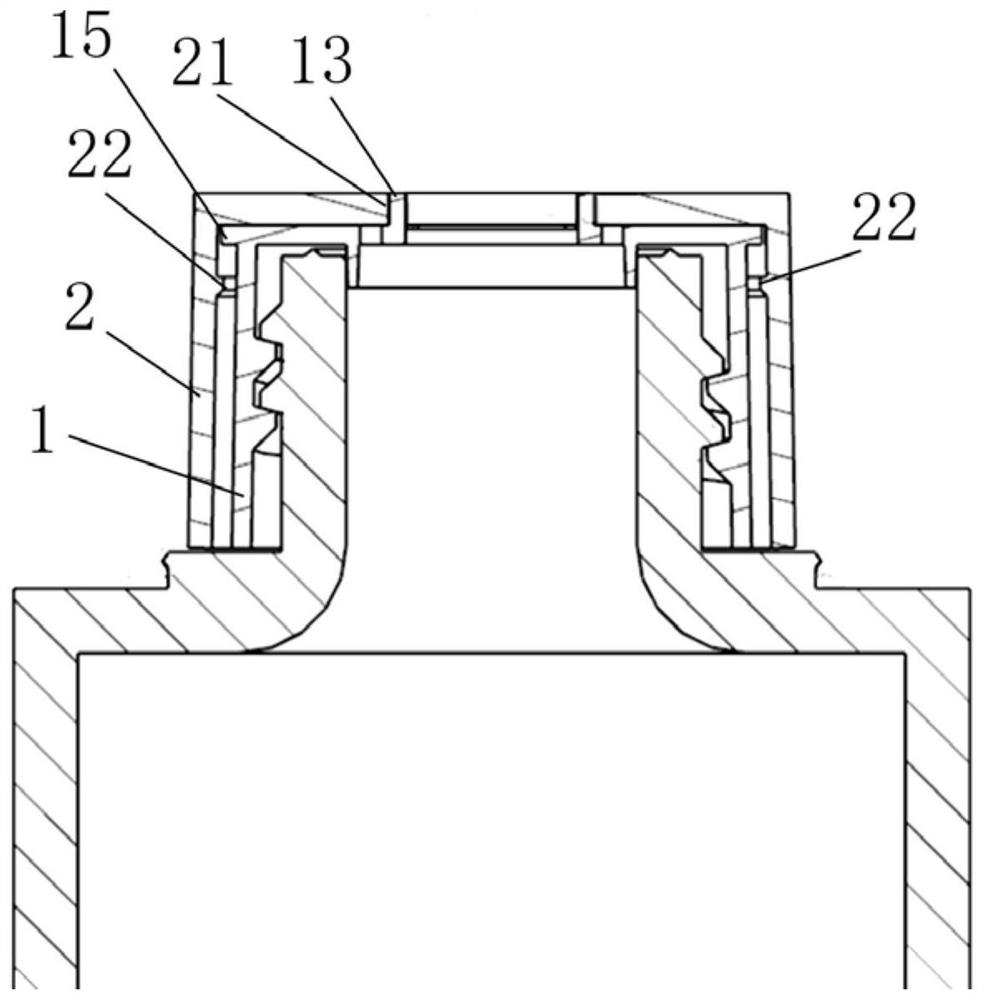

[0029] Such as figure 2 As shown, the inner cap 1 is nested on the bottle mouth. The inner cap 1 and the mouth of the bottle can be nested or integrally formed by int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com