Intelligent suction crane based on optical-mechanical-electrical integration technology

A suction crane, opto-electromechanical technology, applied in cranes and other directions, can solve the problems of poor positioning effect of the mounting frame, poor fixing effect of the suction crane, inconvenient adjustment of the angle of the beam, etc., and achieve the effect of increasing the fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

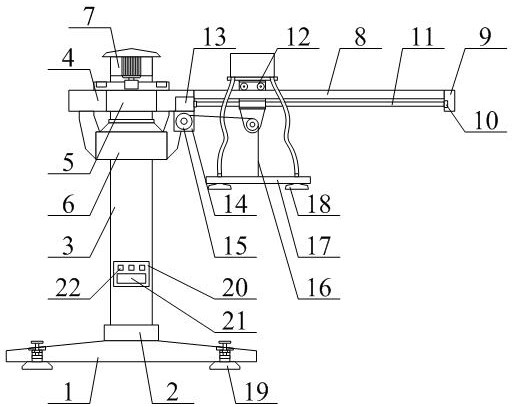

[0041] as attached figure 1 And attached figure 2 shown

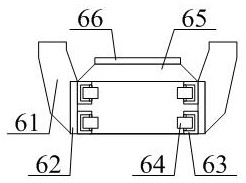

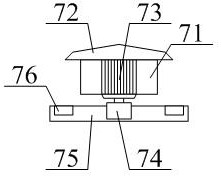

[0042] The present invention provides an intelligent suction hoist based on optomechanical integration technology, which includes a fixed chassis 1, a bottom fixed chassis 2, a longitudinal bracket 3, a beam 4, a ball bearing 5, a reinforced bracket structure 6, and a top rotating frame structure 7. Rectangular bar 8, fixed seat 9, roller bearing 10, threaded rod 11, mobile hanger structure 12, rotating motor 13, winding motor 14, winding roller 15, steel wire sling 16, transverse plate 17, fixed sucker 18, can Adjust the fixed frame structure 19, the console 20, the controller 21 and the control button 22, the bottom fixed frame 2 is welded on the top of the fixed bottom frame 1; the longitudinal support 3 is welded on the top of the bottom fixed frame 2; The beam 4 described above is welded to the outer ring of the ball bearing 5; the inner ring of the ball bearing 5 is sleeved on the outer upper part of the longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com