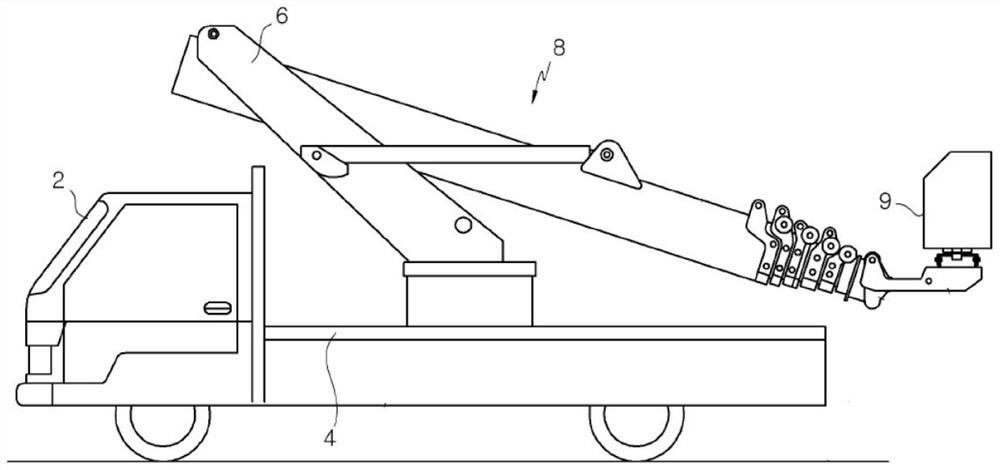

A four-stage boom device for a live-wire operations vehicle

A technology of live working and cantilever devices, which is applied in hoisting devices, lifting equipment safety devices, etc., can solve the problems of increased weight, increased manufacturing costs, and increased size of cantilever devices, so as to improve utilization, optimize the working environment, The effect of preventing the increase of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The terms or words used in the specification and claims should not be interpreted in general or dictionary meanings, and the inventors can properly define the concepts of the terms in order to describe their invention in the best way. Based on this principle, the meaning and concept should be interpreted as conforming to the technical idea of the present invention.

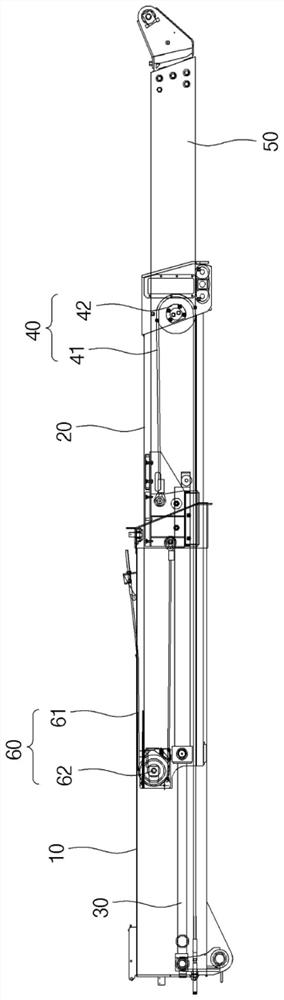

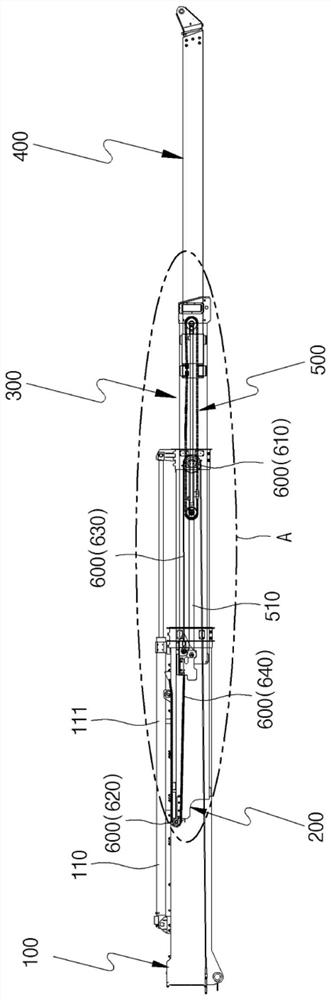

[0065] Refer to the following Figure 3 to Figure 10 A four-stage boom device (hereinafter referred to as "four-stage boom device") for a live working vehicle according to a preferred embodiment of the present invention will be described.

[0066] The four-stage cantilever device is composed of four cantilevers and constitutes a hybrid type, so that the insulating cantilever at the front end of the four cantilevers can be driven independently, and the secondary cantilever and the third-stage cantilever can be pulled in and out in conjunction with each other.

[0067] Since only the insulating cantilever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com