Low-leakage airplane ground air conditioner air supply hose and preparation method

A hose, aircraft technology, applied in the direction of hoses, mechanical equipment, pipes, etc., can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

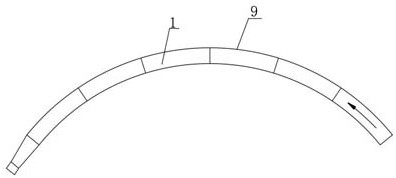

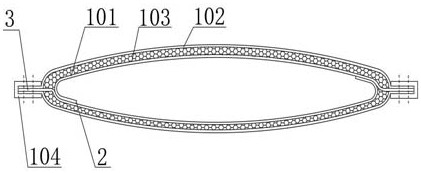

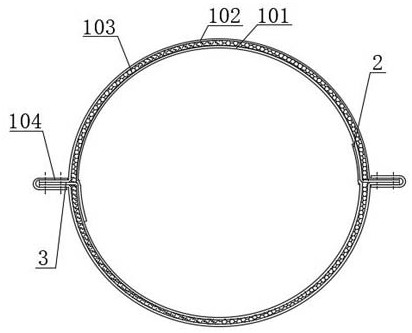

[0030] Example 1 please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 One embodiment shown is a low-leakage aircraft ground air-conditioning air supply hose, including a molded hose 9, and the molded hose 9 includes several connecting hoses 1, and the connecting hose 1 includes two inner adhesive plaster pieces 101 and two edging strips 104, the two sides of each inner rubber cloth sheet 101 are provided with connecting edge strips 2 and sewing edge strips 3, and the two connecting edge strips 2 are pasted and connected with the inner surfaces of the two inner adhesive cloth sheets 101 respectively to form an inner Adhesive tube, each inner adhesive sheet 101 is provided with an insulating layer adhesive sheet 103, and each insulating layer adhesive sheet 103 is provided with an outer adhesive sheet 102, two sewing edge strips 3 and two outer adhesive sheet sheets 102 One end of each is fixedly connected to the inside of the two edging bel...

Embodiment 2

[0032] On the basis of the above examples, please refer to Example 2 Figure 6 An embodiment shown, the two ends of the connecting hose 1 are all sewn with adhesive plaster sheets, a zipper 8, a first buckle suede surface 4 and a second buckle hook surface 7 are sewn on one adhesive plaster sheet, and the other adhesive plaster The sheet is sewn with a zipper 8, a first buckle hook surface 5 and a second buckle suede surface 6, and the first buckle suede surface 4 and the second buckle suede surface 6 are double-layered fabrics that are folded back. The connecting parts of the two connected hoses 1 adopt two buckle cloth loops with opposite overlapping directions, and there are two reversely pasted buckles on the outside of the zipper 8 to block the leakage from the zipper 8 The cold air and hot air can effectively reduce the leakage of the connection parts.

Embodiment 3

[0034] On the basis of the above examples, please refer to Example 3 figure 1 and Figure 4 In one embodiment shown, the forming hose 9 is in the shape of a large arc, the inner adhesive sheet 101, the outer adhesive sheet 102 and the insulation layer adhesive sheet 103 are all in the shape of an arc, and the forming hose 9 is in the shape of a large arc, effectively avoiding This prevents the formation of "dead folds" due to local bending during the air supply process of the connecting hose 1, and reduces the air supply resistance of the connecting hose 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com