Flexible touch screen production and manufacturing physical performance testing method

A technology of flexible touch and physical properties, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying repetitive force/pulsation force, and measuring devices, which can solve the problems of high cost and expensive numerical control equipment, etc. Achieve the effect of low cost, improved convenience and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

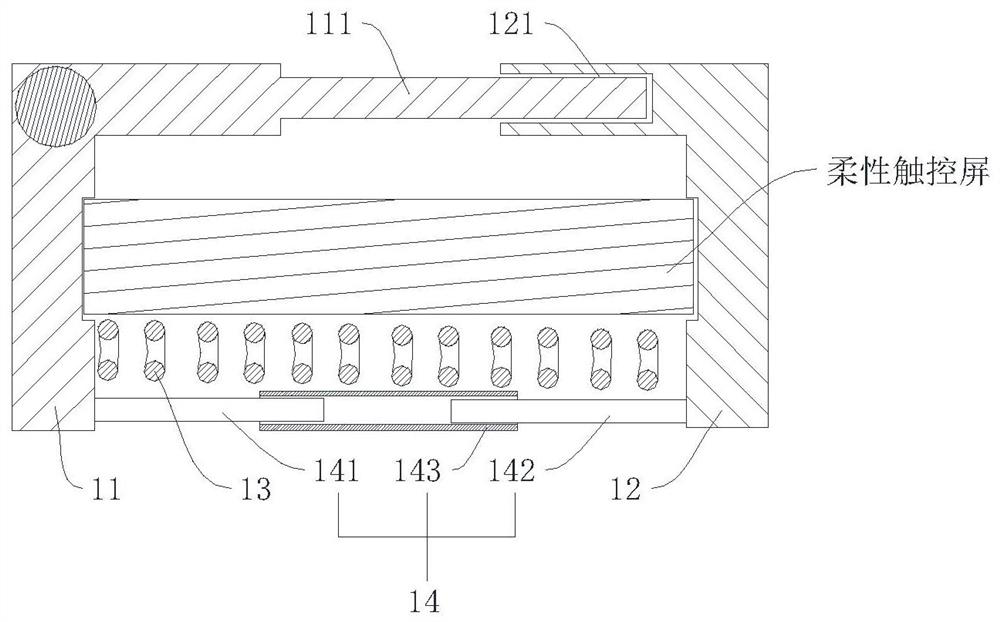

[0036] The following is attached Figure 1-8 The present invention is described in further detail.

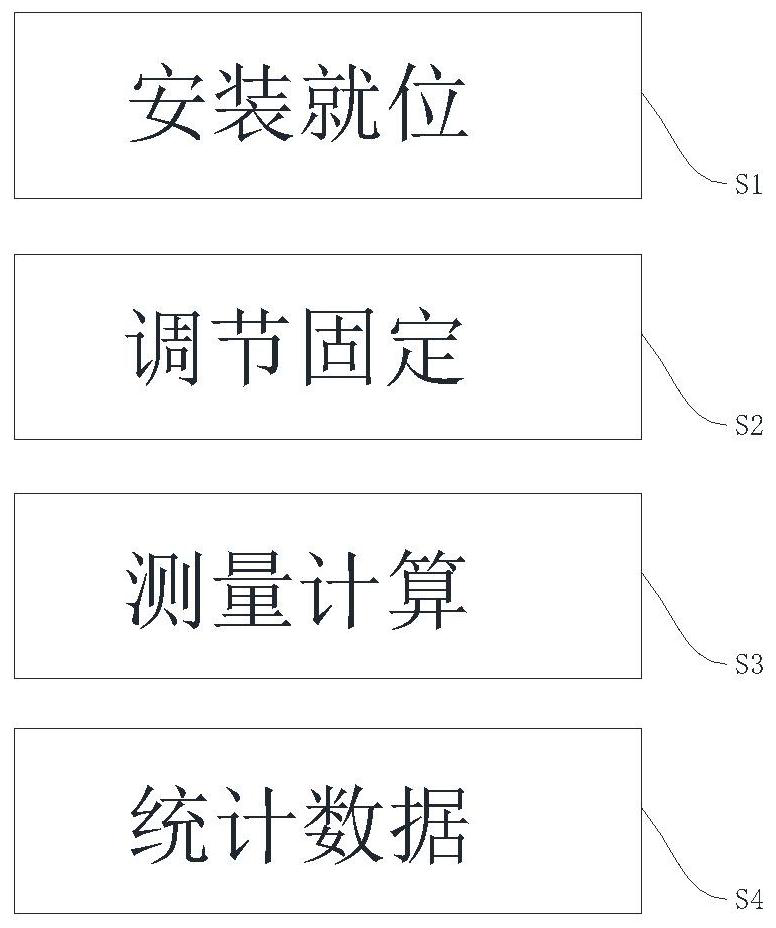

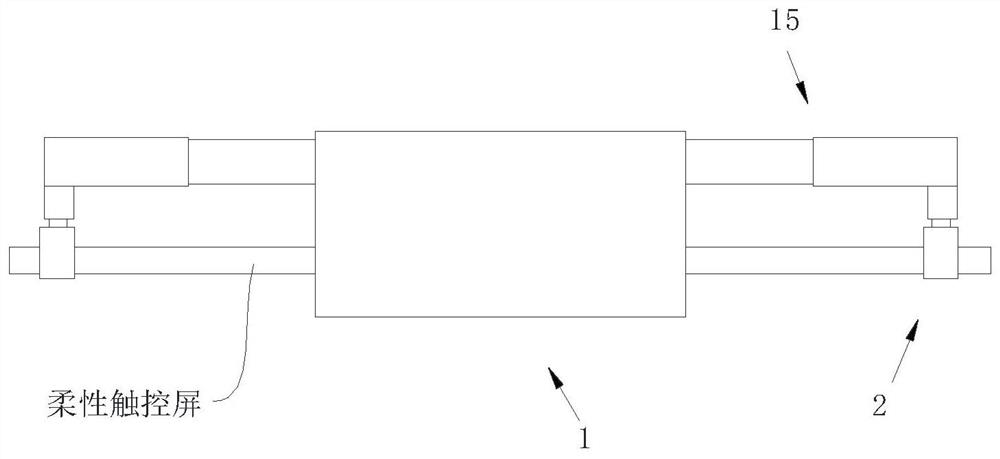

[0037] refer to figure 2 As shown, it is a flexible touch screen manufacturing physical performance testing method disclosed in the present invention, which uses a flexible touch screen manufacturing physical performance testing equipment, and the flexible touch screen manufacturing physical performance testing equipment includes: The fixer 1 is used to fix the flexible touch screen and fix the flexible touch screen at a specific position at a specific angle; the clamping driver 2 is connected to the fixer 1 and symmetrically clamped on the flexible touch screen to drive The flexible touch screen is deformed and bent; the connecting fixture 3 ( Figure 6 , Figure 7 shown in ), which is connected with the holder 1 and the clamping driver 2 and moves synchronously with the clamping driver 2; in the actual use process, the flexible touch screen is fixed by the holder 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com