A UAV-based T-beam construction tracking system and method

A technology of unmanned aerial vehicles and target tracking, which is applied to computer parts, control of finding targets, and devices for collaborative operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

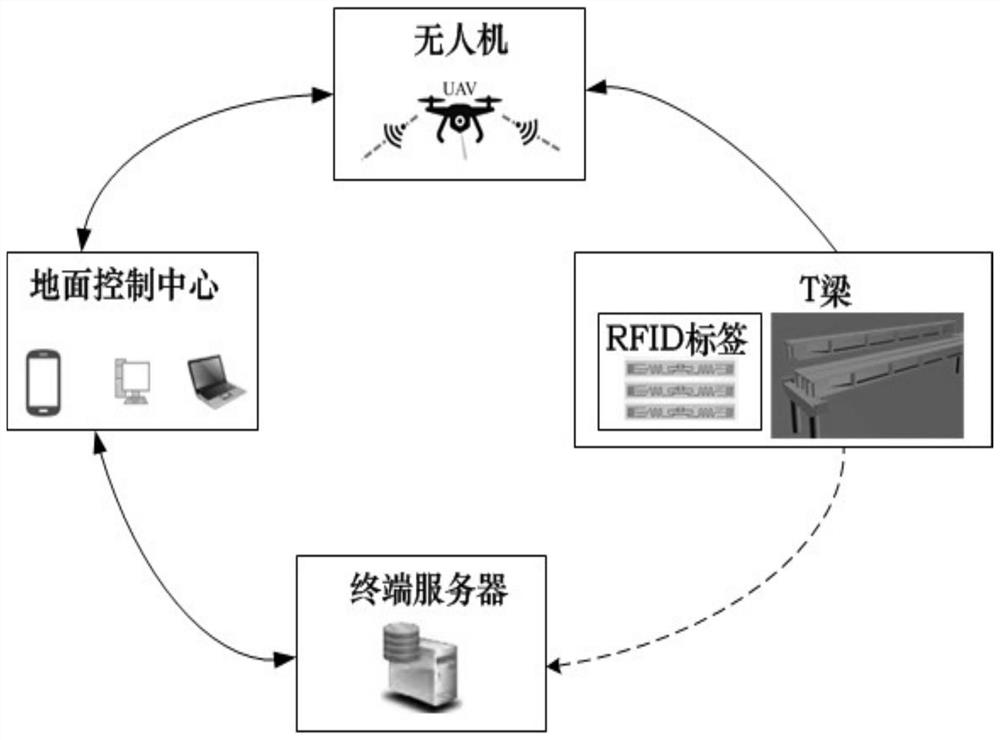

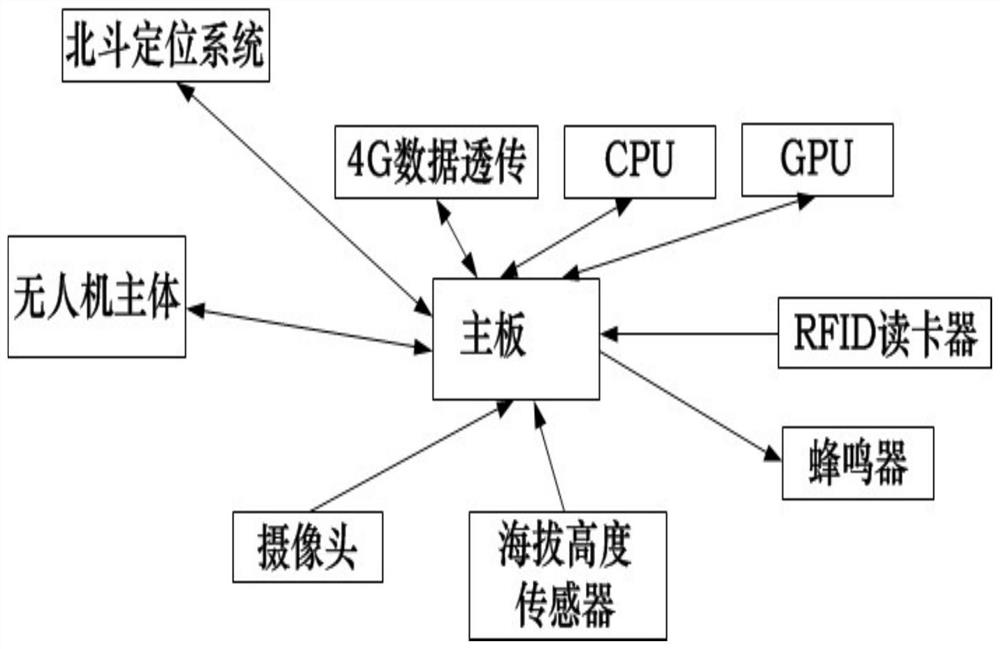

[0046] Implementation method: such as figure 1 , 2 As shown, the UAV-based T-beam construction tracking system includes an RFID tag installed on each T-beam, a UAV, a ground control center, and a terminal server, wherein the UAV is used to collect the T-beams. The beam information is sent to the ground control center; the drone is equipped with a camera, a Beidou positioning module, an altitude sensor, an inertial navigation module, an RFID UHF card reader, a data transparent transmission module, a buzzer and a main board; The RFID tag is used to store the corresponding T-beam data, and is identified by the RFID UHF card reader on the drone; the ground control center is used to receive the video stream and Beidou positioning data sent by the drone, Timestamp, RFID tag number information and process, and send control command information to the UAV, upload data to the terminal server; the ground control center is equipped with a human-computer interaction App; the terminal serv...

Embodiment

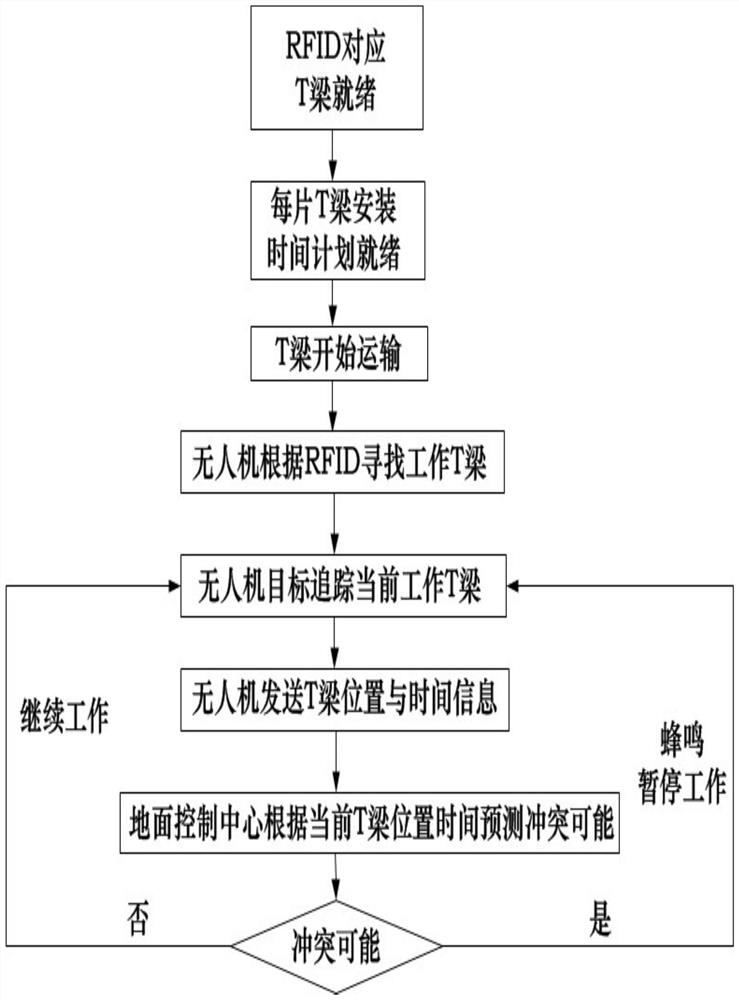

[0050] Example: such as image 3 As shown, this UAV-based T-beam construction tracking method is realized through the UAV-based T-beam construction tracking system described in the above-mentioned implementation mode. Taking the 25mT beam as an example, the specific method flow is as follows:

[0051] (1) An RFID tag with a unique number is fixed on each T-beam stored on the site;

[0052] Specific to this embodiment, the RFID tag can be fixed on the surface of the T beam after the 25mT beam is prefabricated;

[0053] (2) The ground control center makes a corresponding route and time plan for each T-beam, and displays it on the human-computer interaction app in the form of a Gantt chart; so that each T-beam has an appropriate transportation and installation plan;

[0054] (3) The UAV has received the number of the T-beam to be worked, flies into the T-beam site according to the flight plan, uses the airborne RFID UHF card reader to read the T-beam information, and locates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com