Method for converting high-temperature reverse bias aging time of crimping type insulated gate bipolar transistor

A technology of bipolar transistors and aging time, applied in calculation, computer-aided design, CAD circuit design, etc., can solve the problems of accelerated aging model, lack of passivation layer insulation life impact, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

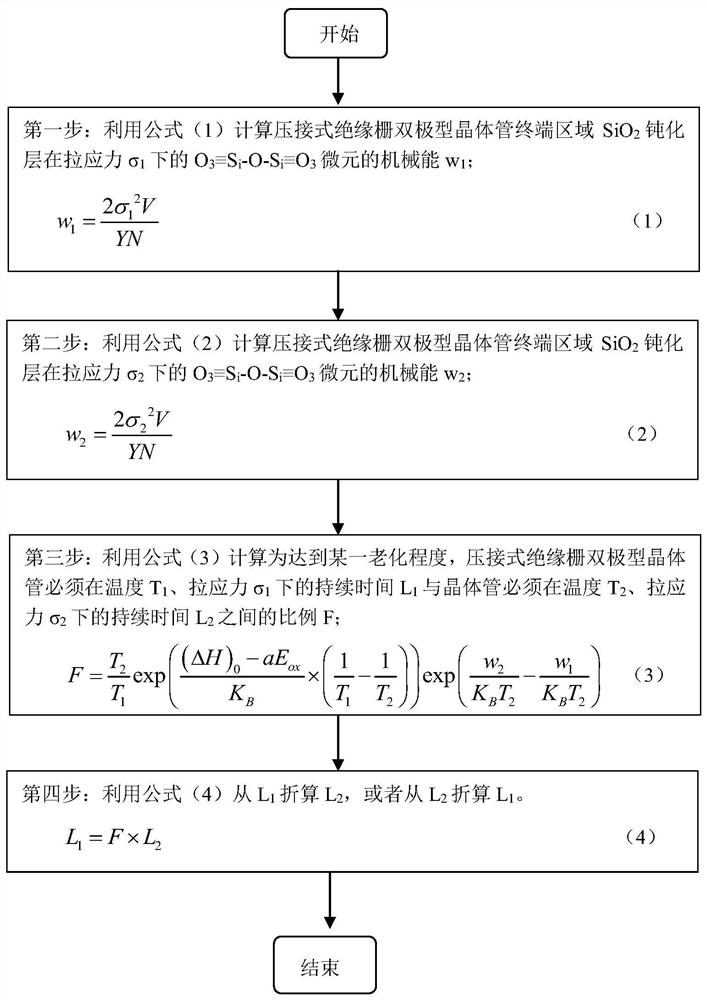

Method used

Image

Examples

Embodiment Construction

[0037] Taking a 3300V / 50A single-chip crimp IGBT device as an example, the specific implementation of the present invention will be described in detail below.

[0038] It is known that under the clamping force of the crimping IGBT, the maximum tensile stress of the passivation layer is 67.1Mpa; when a mechanical pressure of 2Gpa is applied, the maximum tensile stress of the passivation layer reaches 2.8Gpa, and the electric field strength on the passivation layer in the terminal area is as high as 200kV / cm. When a certain type of press-connect IGBT is subjected to a high-temperature reverse bias test, the temperature T 1 is 423K, the device is subjected to external mechanical pressure (the pressure is kept at 2Gpa, then the maximum tensile stress σ of the passivation layer 1 Reach 2.8Gpa), get the accelerated aging life of the device L f-test 200 hours, it is necessary to calculate the actual working conditions (temperature T 2 is 323K, the maximum tensile stress σ of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com