Novel heating and atomizing device

A new type of heating atomization technology, applied in the direction of tobacco, etc., to achieve the effect of avoiding potential leakage safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

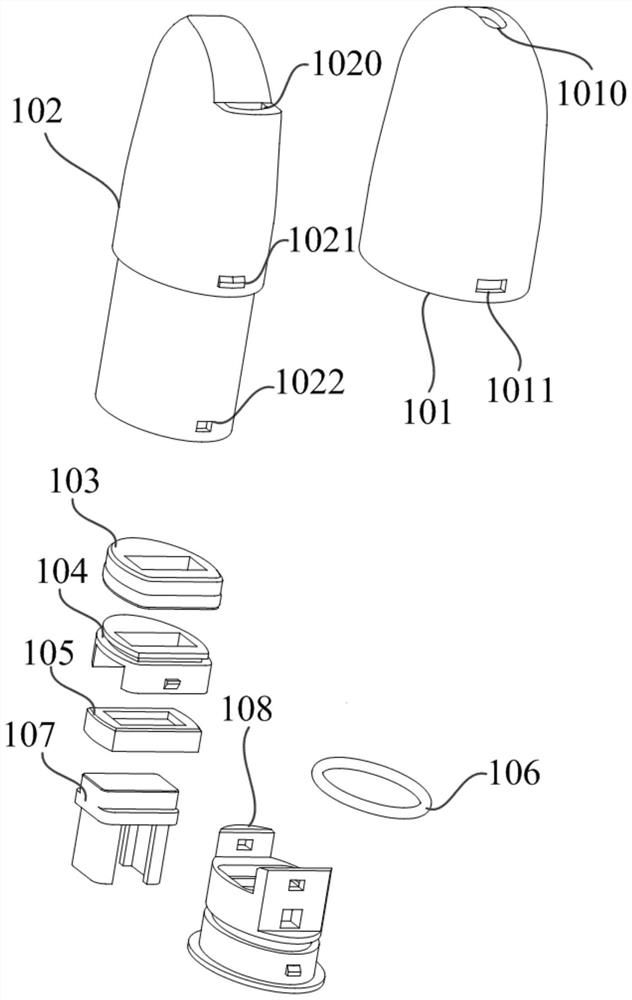

[0051] As an embodiment of the present invention, the liquid storage container further includes a sealing ring 106, which is sleeved on the outside of the lower cover 108 of the cartridge to prevent the liquid from seeping out from the side wall of the lower cover 108 of the cartridge .

[0052] As an embodiment of the present invention, the heating atomization device also includes a heating element bracket 210; the heating wire 211 and the base 212 are placed in the heating element bracket 210; the heating element bracket 210 is a cylindrical structure with an upward opening, and the second shell The lower half of 102 is sheathed between the periphery of the heating wire 211 and the side wall of the heating element bracket 210 , so that the top of the heating wire 211 is in contact with the oil seepage material 107 .

[0053] As an embodiment of the present invention, the heating atomizing device further includes a battery 23, a control board 22 and a charging board 24, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com