Bottom oil way mechanism of cylinder body of hinge beam of six-face top hydraulic machine

A six-sided top hydraulic and hinged beam technology, which is applied in the direction of fluid pressure actuating devices, can solve problems such as easy deflection of cone plugging, hinged beam leakage, oil leakage, and difficult installation and operation, so as to improve production efficiency and improve durability. Compression and compression resistance, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] Provide the specific embodiment of the present invention below in conjunction with accompanying drawing as follows:

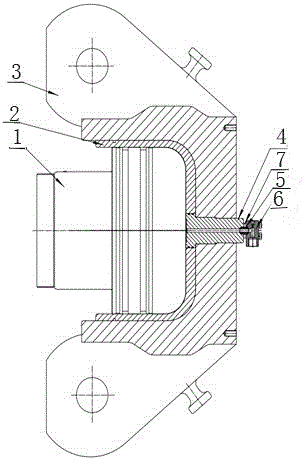

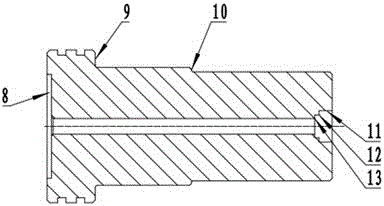

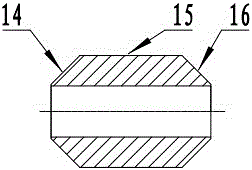

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the oil circuit mechanism at the bottom of the hinged beam cylinder body of a six-sided top hydraulic press of the present invention is mainly composed of a rear plug 4, a cone plug 5, a three-way valve member 6, and a connecting bolt 7; wherein: the circumference of the rear plug 4 The body is respectively provided with anti-compression steps 9 and two anti-compression steps of anti-compression steps 10; the assembly position of the rear plug 4 on the hinge beam 3 and the working cylinder 2 reaches the anti-compression steps 9, and when the pressure increases to a certain amount, the anti-compression The pressure step 10 can realize secondary pressure resistance. In the working direction of the rear plug 4, a concave oil groove 8 is provided on the contact surface between the rear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com