A two-way buffer hydraulic cylinder

A two-way buffer and hydraulic cylinder technology, applied in the direction of fluid pressure actuation device, can solve the problem of not installing two buffer devices, achieve superior performance, improve buffer effect, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

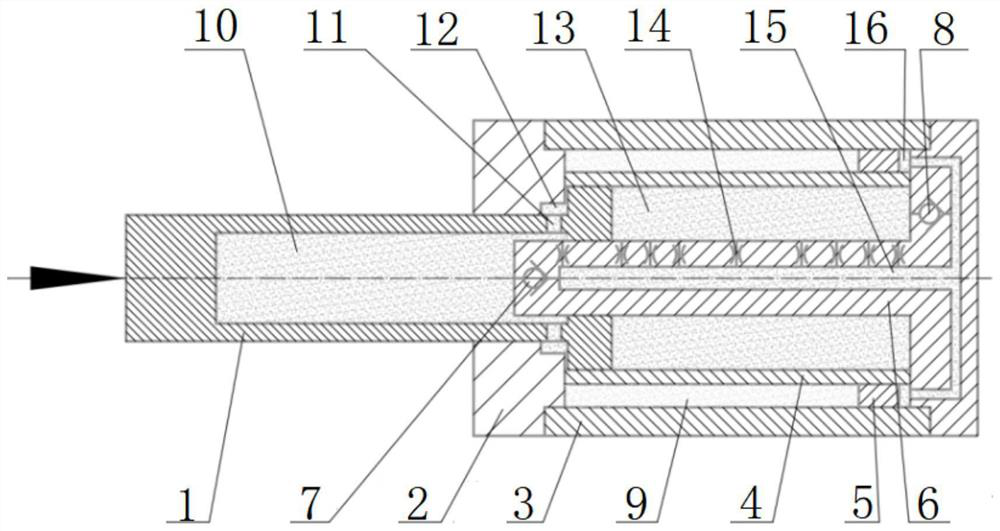

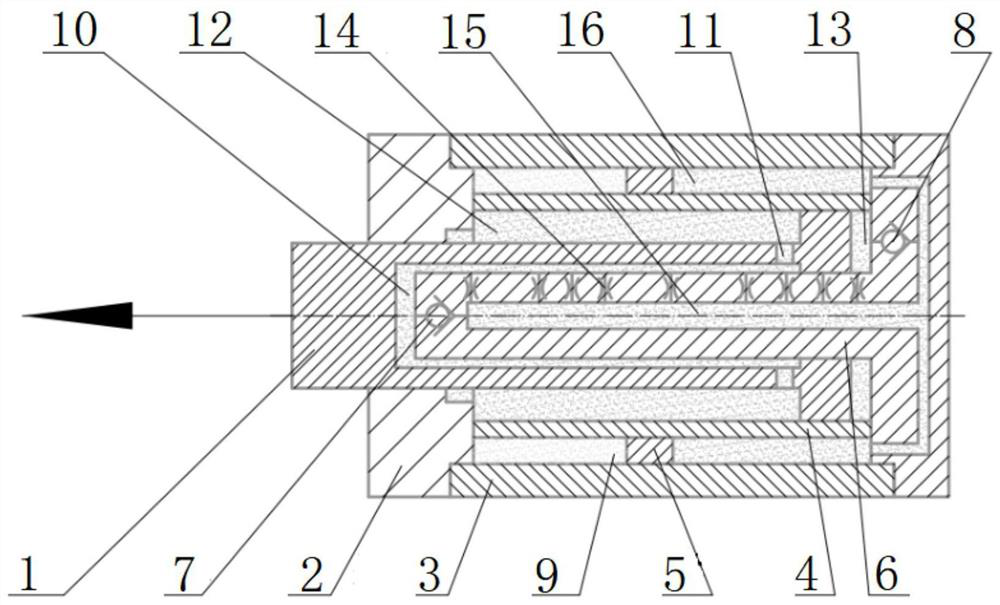

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0031] This embodiment provides a two-way buffer hydraulic cylinder, which utilizes the orifice throttling feature to realize the buffer function of the piston rod 1 during the two-way process of extension and retraction, and can realize buffer functions under various load characteristics.

[0032] like figure 1 and 2 As shown, the two-way buffer hydraulic cylinder includes: piston rod 1, cylinder head 2, outer cylinder 3, inner cylinder 4, spacer sleeve 5, throttle rod 6, one-way valve A7 and one-way valve B8.

[0033] The connection relationship of the two-way buffer hydraulic cylinder is as follows: the throttle rod 6 is a hollow tube with an opening at one end and a hole at the other end, and its internal cavity is an oil chamber D15. It is fixedly connected with one end of the outer cylinder 3 to realize the coaxial assembly of the throttle rod 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com