Electrostatic dust collection equipment capable of automatically replacing electrode plate

An electrostatic dust removal and automatic replacement technology, applied in the field of static electricity, can solve the problems of affecting the dust adsorption effect and not being able to automatically clean the dust on the electrode plate, so as to achieve the effect of enhancing the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

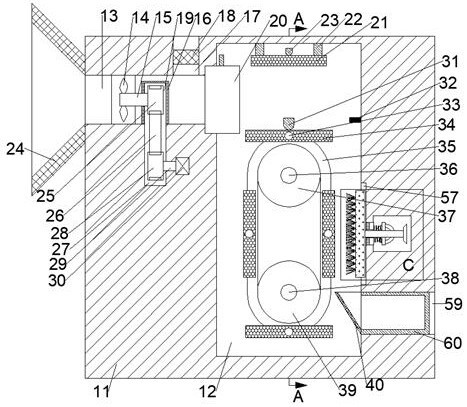

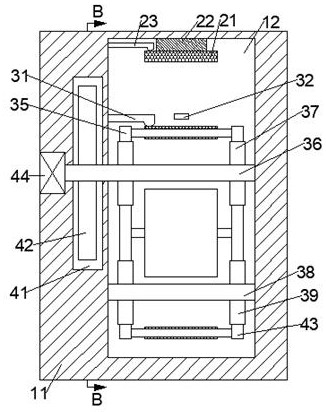

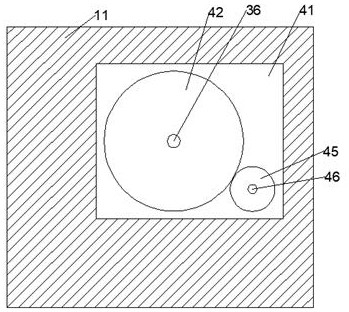

[0018] Combine below Figure 1-Figure 4 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] An electrostatic precipitator capable of automatically replacing electrode plates according to the present invention includes a body 11, a dust adsorption chamber 12 is provided inside the body 11, and a feed channel communicating with the outside is provided on the left side of the dust adsorption chamber 12 13. The left end surface of the corresponding position of the feed channel 13 is fixed with a dust collection cover 24, the dust collection cover 24 can increase the dust particles floating in the absorption chamber, and the circular surface at the middle position of the acceleration gear chamber 41 is fixed with a The fan pulley cover 16, the inside of the fan pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com