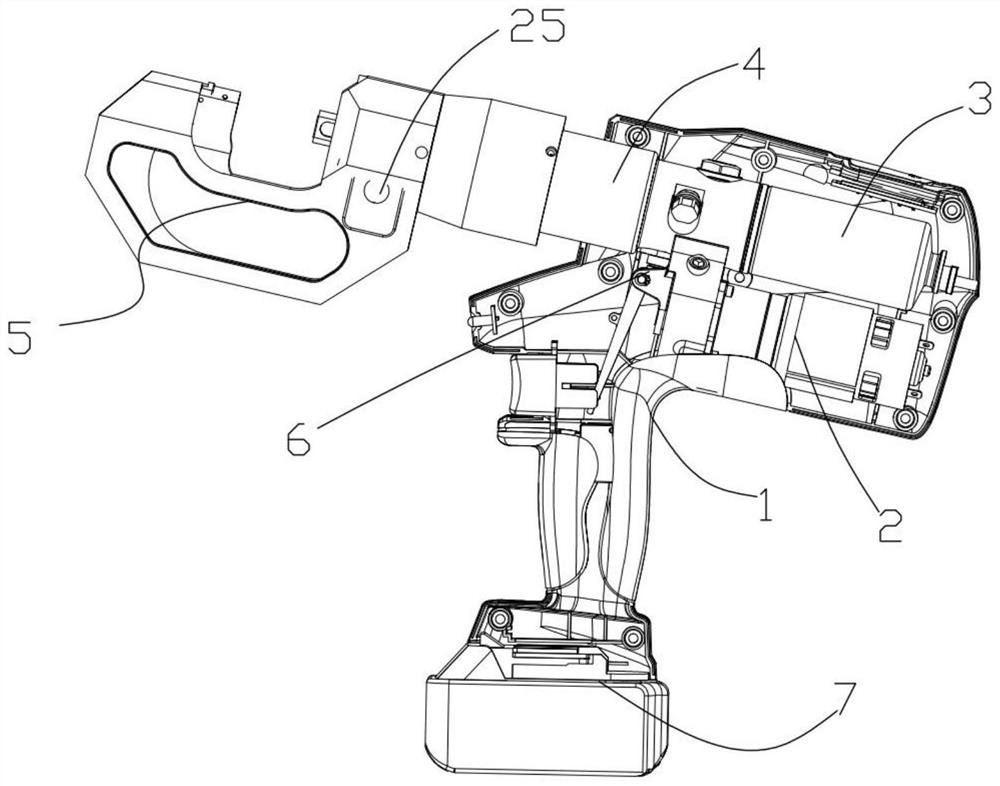

An intelligent control hydraulic tool

A hydraulic tool, intelligent control technology, applied in the direction of manufacturing tools, punching machines, presses, etc., can solve the problems of poor replacement performance, large processing head limitations, poor response of the pressure relief mechanism, etc., to achieve stable structure of the pressure relief mechanism, Improve the effect of using intelligence and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

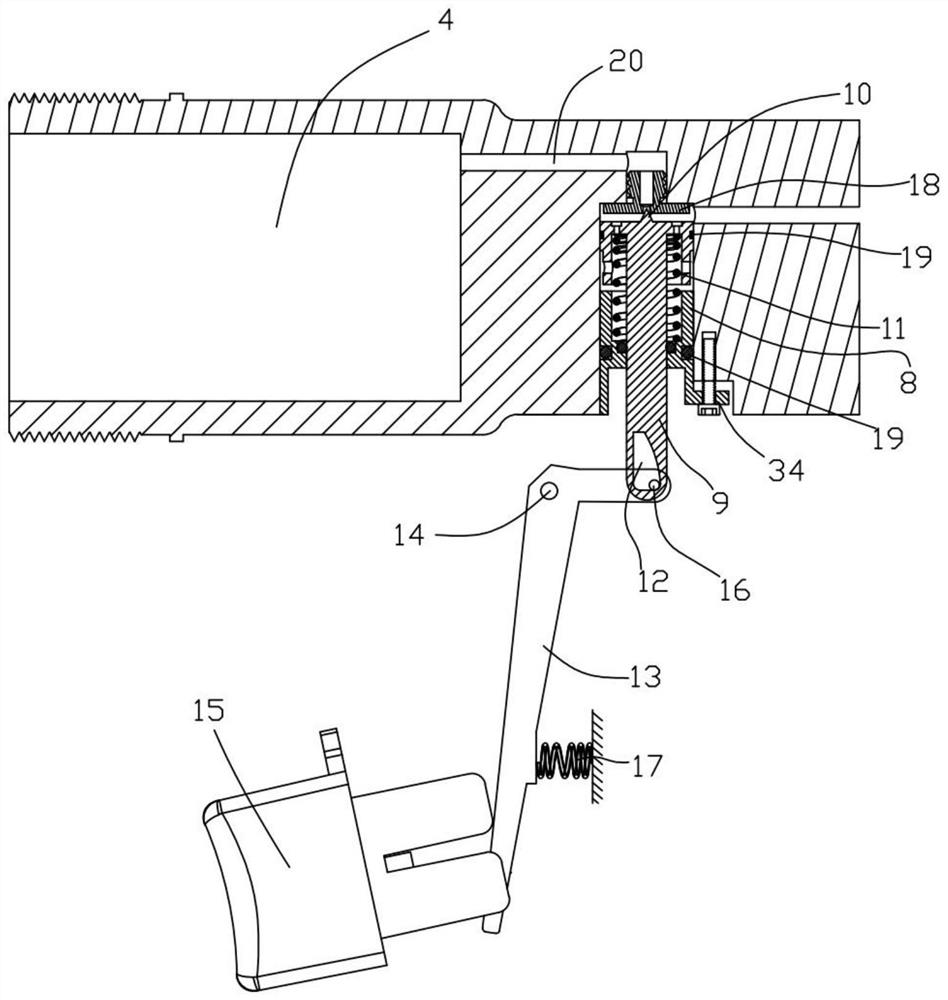

Embodiment 1

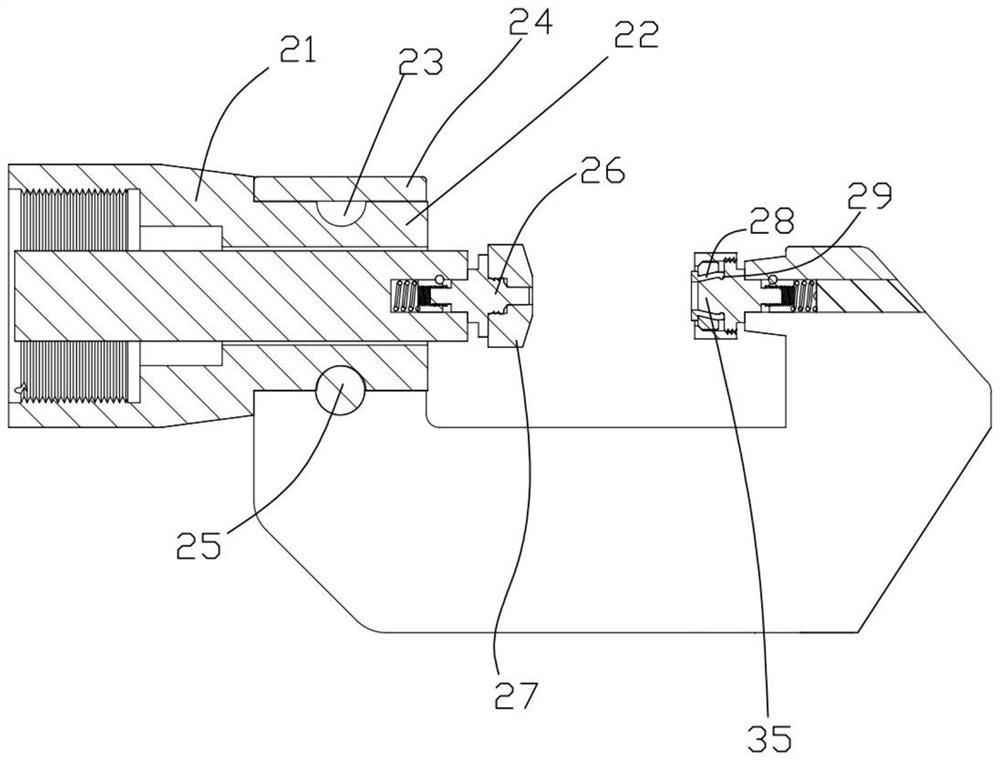

[0031]The fixed head includes a C-shaped head, one end of the C-shaped head is provided with a ring sleeve 24, and the inner wall of the ring sleeve 24 is provided with a perforation, and the perforation corresponds to the inner ring 23 and is inserted with a fixing pin 25, The ring sleeve 24 and the inset ring 23 of the installation part 22 are limited by the fixing pin 25. The output end of the oil cylinder 2 is connected with a punch 26, and the punch 26 is covered with an elastic pad 27, and the punch 26 wears Through the elastic pad 27, the other end of the C-shaped head is provided with a die, and the die includes an equal segment block 28 arranged in a trisecting ring, and the outer portion of the equal segment block 28 is provided with an elastic ring. Equally divided block 28 is provided with a limiter 35, the bottom of the limiter 35 is provided with a ring groove, the bottom of the equalized block 28 is provided with a spherical block 29, and the spherical block 29 i...

Embodiment 2

[0033] Be set as movable head, movable head then comprises square bar 36, and square bar 36 one ends are provided with ring sleeve 24, and the other end is then covered with movable block, die is installed on the movable block, punch 26 concaves of the present embodiment The mode of mold installation is the same as that of Embodiment 1, all of which are connected by threads. The lower part of the movable block is provided with a locking groove 37, and a locking pin 38 is inserted in the locking slot 37. The locking pin 38 is arranged on a spring for positioning. The position of the movable block and the square rod 36 can further process thicker plates, improving the applicability of use.

[0034] In addition, the riveting head can also be replaced with a punching head, only need to change the mould, and because the pressure in the hydraulic tool processing process is relatively large, after the die and the punch 26 connected by the thread receive the force, it will cause seriou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com