Small lathe rapid transposition tool rest device

A technology of indexing and tool rest, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of low processing efficiency and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

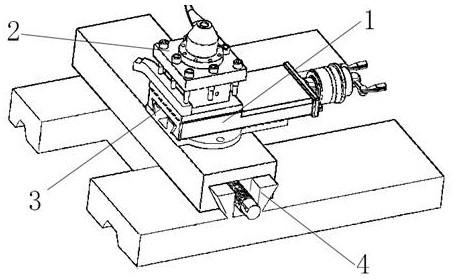

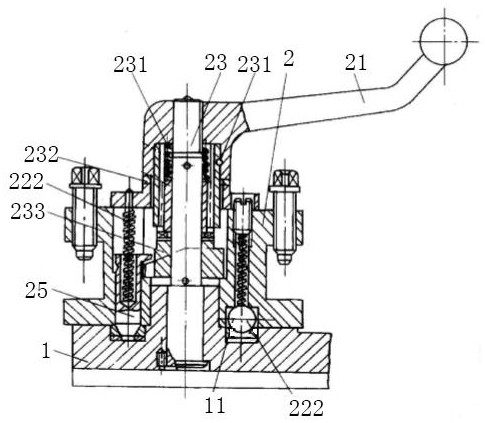

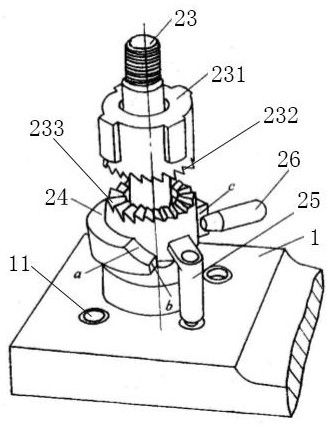

[0028] Refer to attached Figure 1-5 , a small-sized lathe quick indexing tool holder device, including a base 1 and a clamping structure, one side of the base 1 is provided with a square tool holder body 2 for matching rotation, and the other side of the base 1 is provided with an axial feed structure 3 and a radial feed structure 4, wherein the square tool holder 2 is provided with a rotation positioning structure, and the rotation positioning structure includes a 45-degree direction index and a 90-degree direction index.

[0029] The rotation positioning structure includes a handle 21, the handle 21 is externally matched and connected to the cover plate 22, the middle part of the bottom surface at one end of the handle 21 is connected to the top of the rotating shaft 23 through threaded engagement, and the rotating shaft 23 and the handle 21 are provided with a limiter. position, so that the handle 21 cannot fall off from the rotating shaft 23, the bottom bearing of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com