Municipal PVC tree pool cover plate grooving device

A tree pool and cover plate technology, applied in the municipal field, can solve the problems of waste of resources, damage to plastic plates, high maintenance costs, etc., and achieve the effect of fast and accurate indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

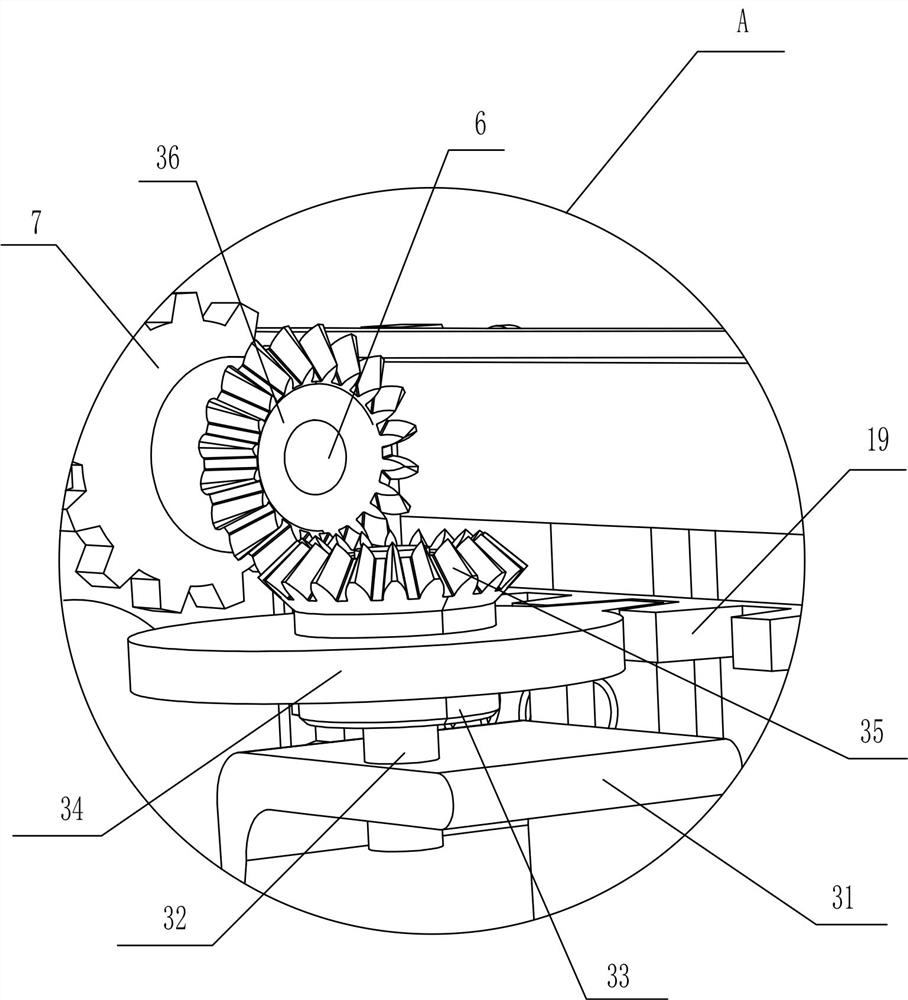

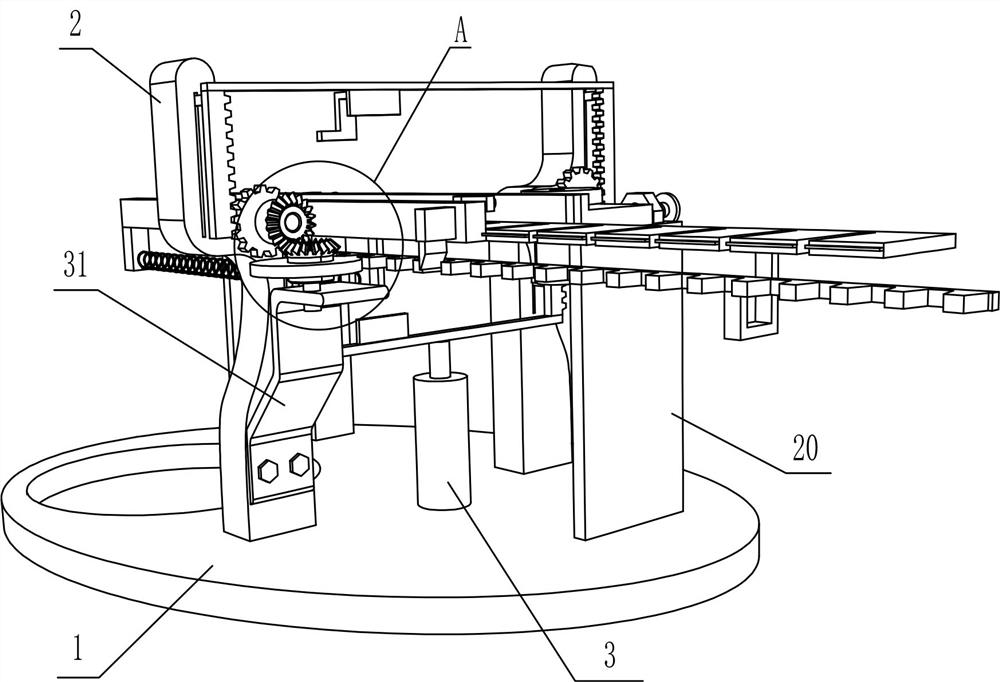

[0024] A kind of municipal PVC tree pool cover slotting device, such as Figure 1-5 As shown, it includes a base plate 1, a bracket 2, an indentation mechanism, a push block 11, a guide bar 12, a limit mechanism, a moving plate 16, a connecting rod 17, a spring 18, a long rack 19, a support 20, and a baffle 21. Nut 22 and screw rod 23. The upper middle part of the bottom plate 1 is fixedly connected with a bracket 2 front and back symmetrically. An indentation mechanism is arranged on the bracket 2 and the bottom plate 1. The push block 11 is arranged on the indentation mechanism. On the front side bracket 2 Fixedly connected with a guide bar 12, the guide bar 12 is provided with a limit mechanism, the rear side of the guide bar 12 is slidably connected with a moving plate 16, and the left and right sides of the moving plate 16 are fixedly connected with a connecting rod 17 symmetrically, and the left connecting rod 17 is connected to the guide bar. A spring 2 18 is connected ...

Embodiment 2

[0027] On the basis of Example 1, such as Figure 4-5 As shown, the indentation mechanism includes an electric push rod 3, a lower push rod 4, a lower rack 5, a rotating shaft 6, a large gear 7, an upper rack 8, an upper push rod 9 and a cutter 10. The side is fixedly connected with an electric push rod 3, and the electric push rod 3 is located between the brackets 2. The top of the electric push rod 3 is fixedly connected with a lower push rod 4, and the upper side of the lower push rod 4 is fixedly connected with a lower rack 5 symmetrically front and rear. The bar 5 slides in the chute at the bottom of the bracket 2, the middle part of the bracket 2 is rotatably connected with a rotating shaft 6, the rotating shaft 6 is fixedly connected with a large gear 7, the lower rack 5 meshes with the large gear 7, and the chute at the top of the bracket 2 The upper rack 8 is slidingly connected inside, and the upper rack 8 meshes with the large gear 7. An upper push rod 9 is fixedly ...

Embodiment 3

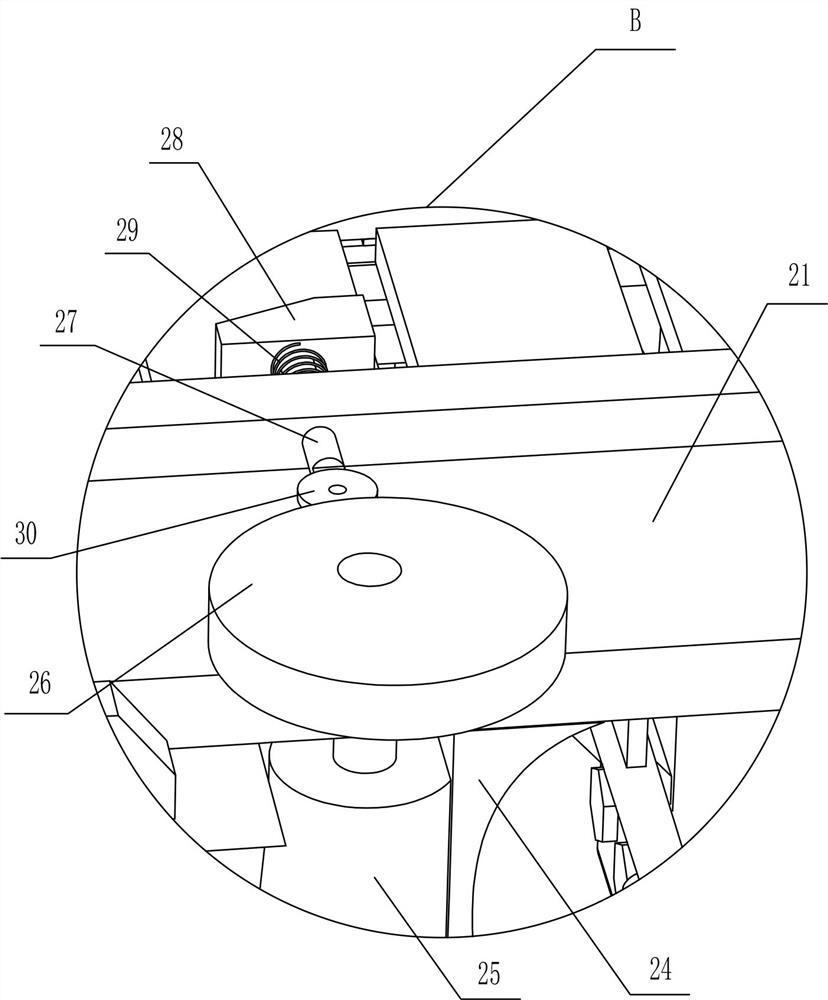

[0032] On the basis of Example 2, such as Figure 6-7Shown, also include bracing frame 24, motor 25, eccentric wheel 26, movable rod 27, extruding block 28, spring three 29 and pulley 30, baffle plate 21 right side lower sides are fixedly connected with bracing frame 24, and bracing frame 24 The right side is fixedly connected with a motor 25, and the top of the output shaft of the motor 25 is fixedly connected with an eccentric wheel 26, and the upper side of the right side of the baffle plate 21 is slid to be provided with a movable rod 27, and the front end of the movable rod 27 is fixedly connected with an extruding block 28. A spring three 29 is connected between the briquetting block 28 rear side and the front side of the baffle plate 21, and the spring three 29 is sleeved on the movable rod 27, and the rear end of the movable rod 27 is rotatably connected with a pulley 30, and the pulley 30 contacts with the eccentric wheel 26.

[0033] Also includes support plate 31, r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap