Automatic indenting machine

一种压痕机、自动的技术,应用在金属加工机械零件、其他制造设备/工具、大型固定成员等方向,能够解决设备造价高、消耗大电能、质量差等问题,达到操作方便、节省能耗、降低难度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

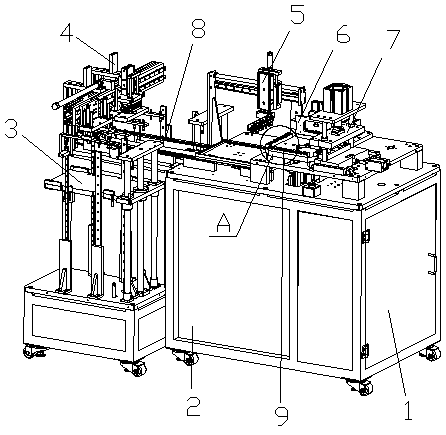

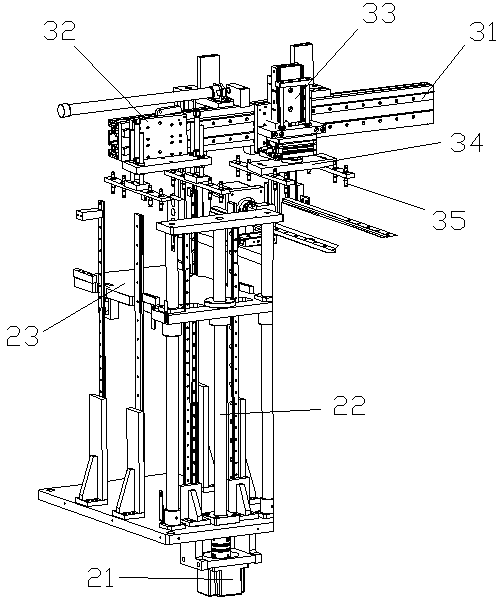

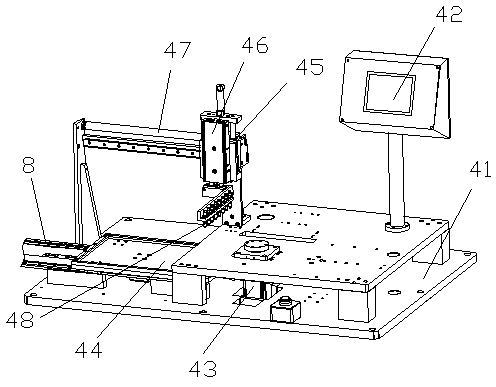

[0038] Such as Figure 1-Figure 6 As shown, the specific structure of the present invention is: an automatic indentation machine, which includes a frame, and the frame is provided with a power distribution control box 2 and a touch operation screen 42 that cooperate with each other. Case 2 is provided with workbench platen 41, and described workbench platen 41 is provided with support and the rotary motor 43 that passes out support, and described rotary motor 43 is provided with square rotary table 11, and described The upper four edges of the rotary table 11 are provided with a loading mold 9 that co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com