Powdery material sample riffle divider and using method thereof

A technology of powdery material and dichotomizer, applied in the direction of sampling device, etc., can solve the problems of inability to uniformly sample materials, loss of accuracy of samples, questioning of representativeness of samples, etc., and achieve the effect of simple structure, easy operation and accurate reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

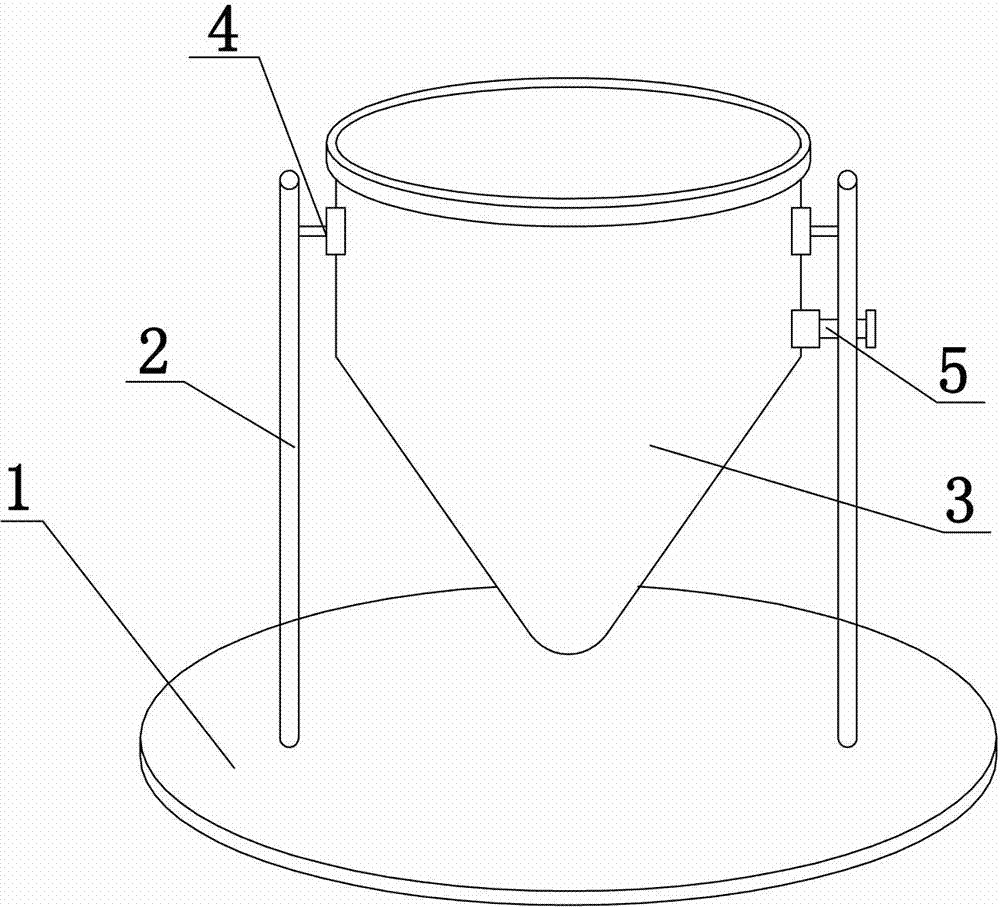

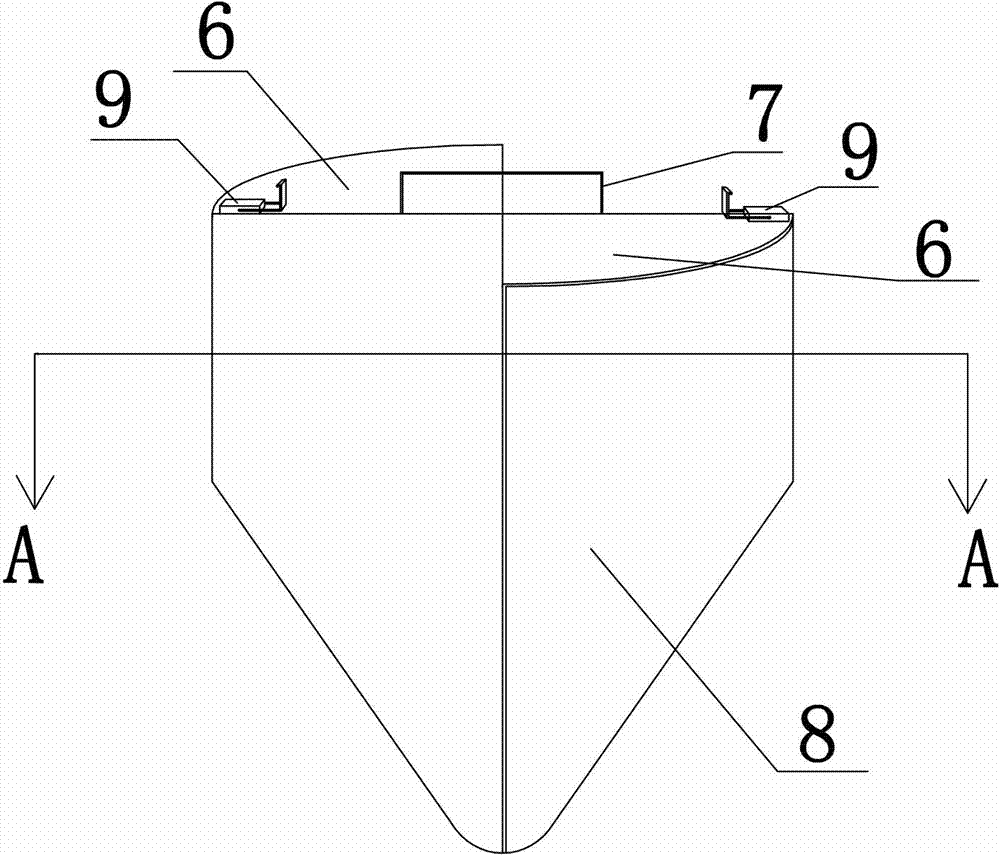

[0022] The specific embodiments of the present invention are further described below with reference to the accompanying drawings.

[0023] like figure 1 , 2 As shown in , 3 and 4, the powdery material sample divider of the present invention is characterized in that it comprises an overturning bucket and a divider arranged in the overturning bucket, and the overturning bucket comprises a base 1, which is located in the The bracket 2 on the base 1, the material barrel 3 which is arranged on the bracket 2 and is rotatably connected to the bracket 2 through a pair of turning shafts 4, is arranged on the bracket 2 and is located under one of the turning shafts 4. pin 5,

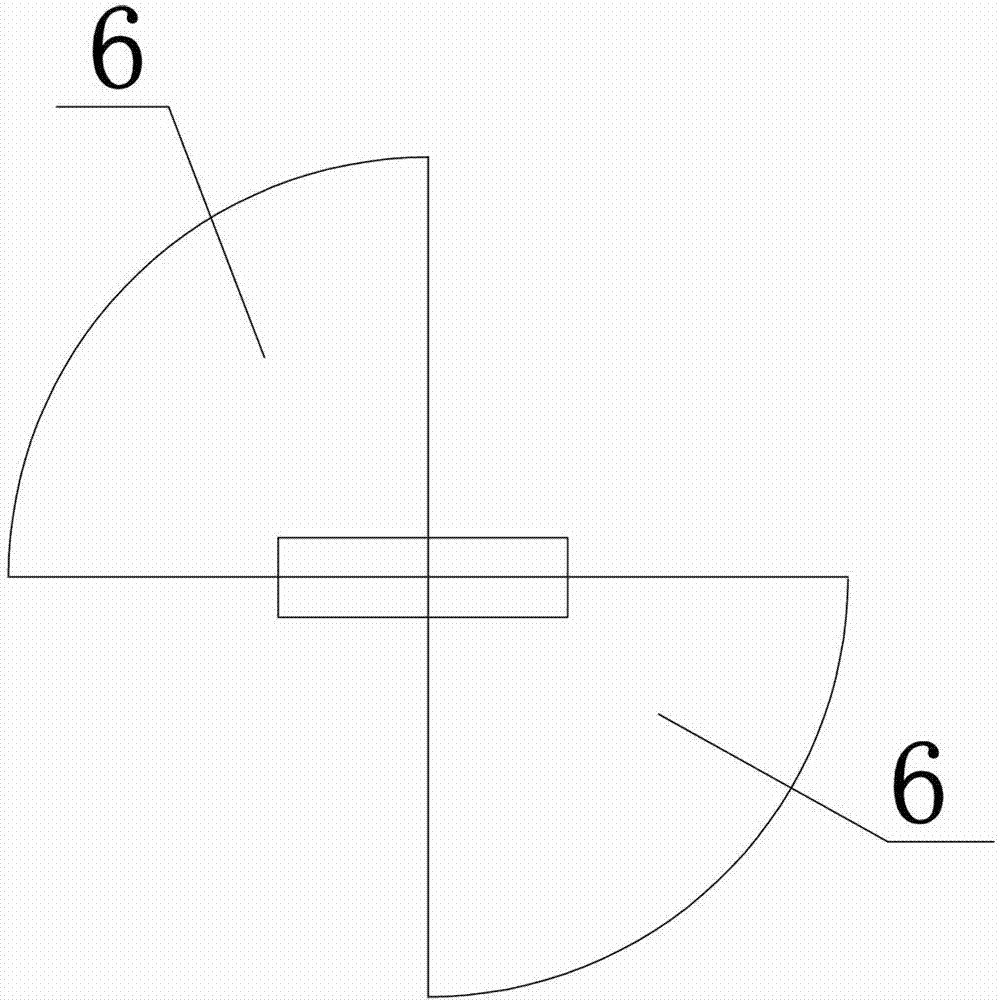

[0024] The said feeder includes two feeder plates 8 that are vertically arranged and crossed, and two stopper plates 6 arranged at the top of the two feeder plates 8 and arranged diagonally. The handle 7 at the top of the material plate 8 is respectively provided with two locks 9 on the two material baffle plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com