Thermal pressure-maintaining device

A pressure-holding device and pressure head technology, which is applied in the field of electronic product processing, can solve the problems of difficult weight control, easy-to-stick material of the pressure-holding head, and high production cost of rubber-covered parts, so as to achieve stable and reliable heat-holding pressure, and easy to avoid The effect of sticky material and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

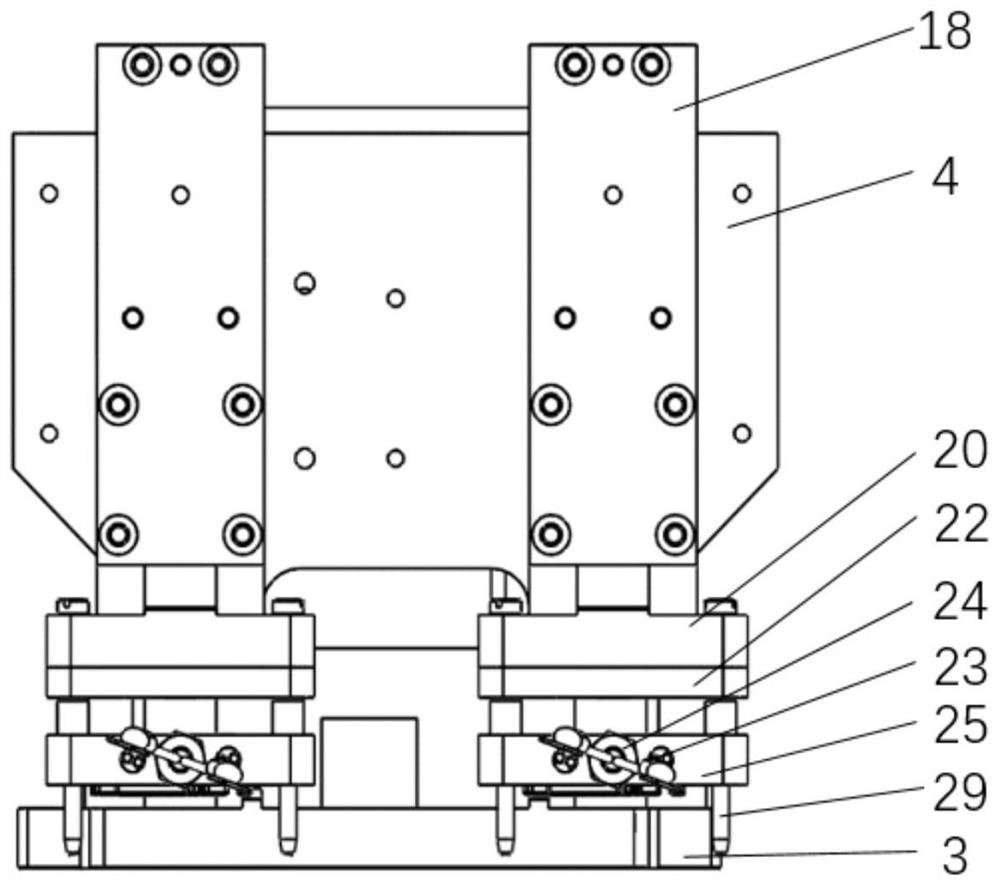

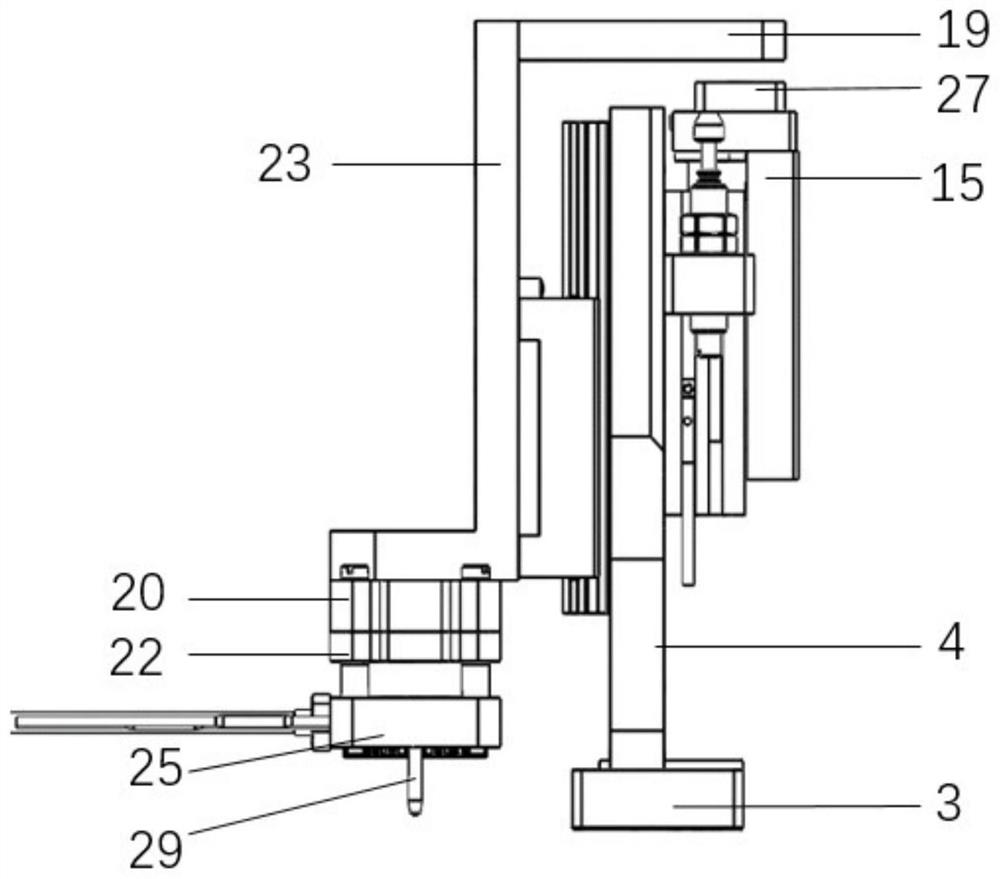

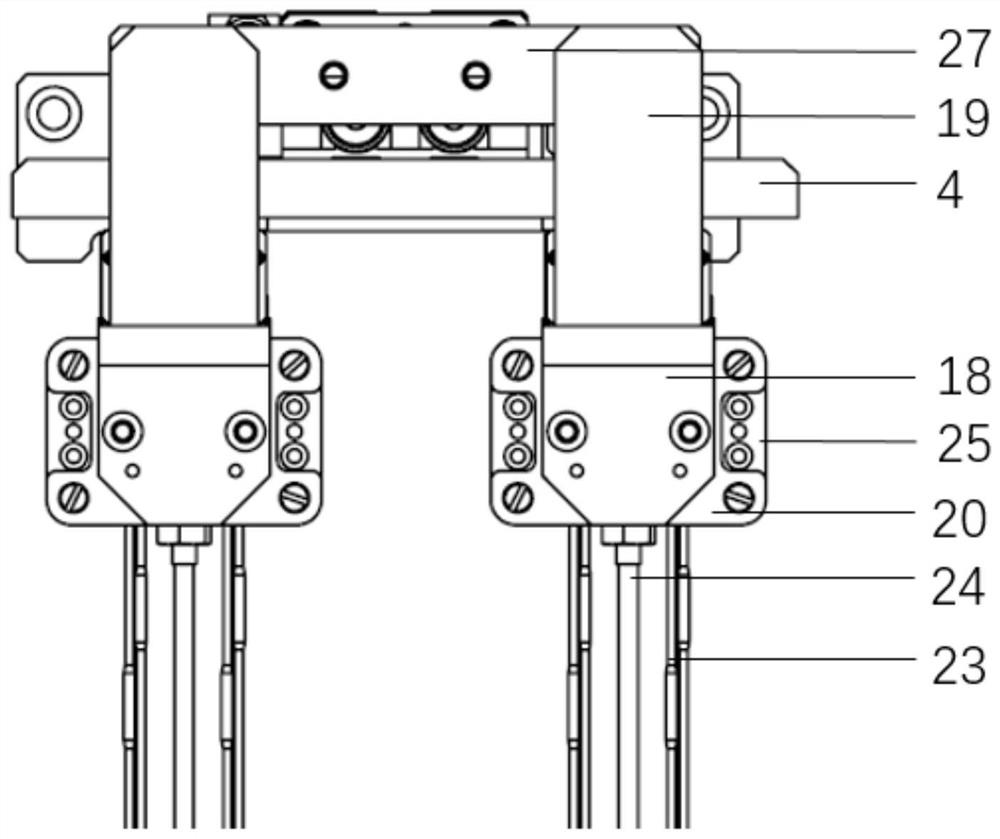

[0052] This embodiment provides a thermal pressure holding device, such as Figure 1~5 As shown, it includes: bottom plate 3, vertical plate 4, first slide cylinder 15, guide rail 9, slider 10, L plate 18, baffle plate 19, fixed block 20, heat insulation plate 22, heating rod 23, temperature controller Induction head 24, spring 25, pressure holding head 26, guide column 29;

[0053] Wherein, the vertical plate 4 is fixed on the base plate 3, the first slide table cylinder 15 is fixed on the back side of the vertical plate 4, the guide rail 9 is fixed on the front of the vertical plate 4, the L plate 18 is fixed on the slider 10, and the L plate 18 is connected with The fixed block 20, the fixed block 20, the heat shield 22, the spring 25, and the pressure-holding head 26 are connected into a whole through the connecting screw in turn from top to bottom. The induction head 24 is connected on the pressure-holding head 26 through its own thread and nut, and one end of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com