Printing device for screen printer and using method thereof

A technology for screen printing machines and printing devices, applied to screen printing machines, general parts of printing machinery, printing machines, etc. It is inconvenient to adjust the angle of the squeegee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

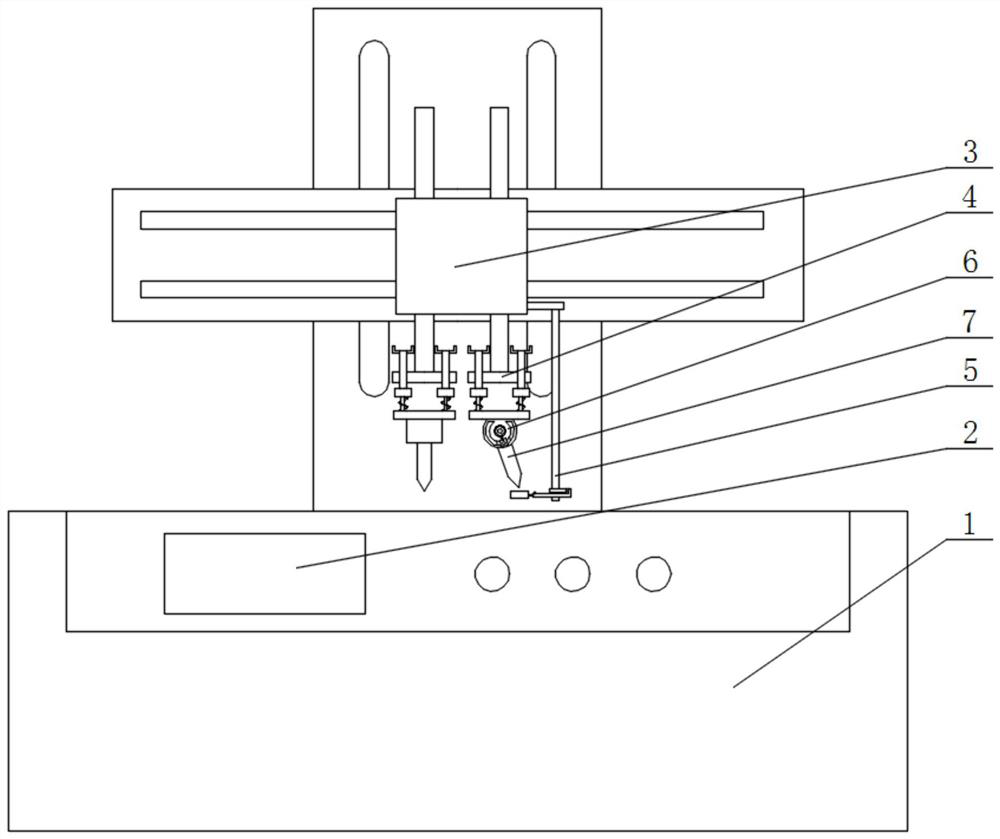

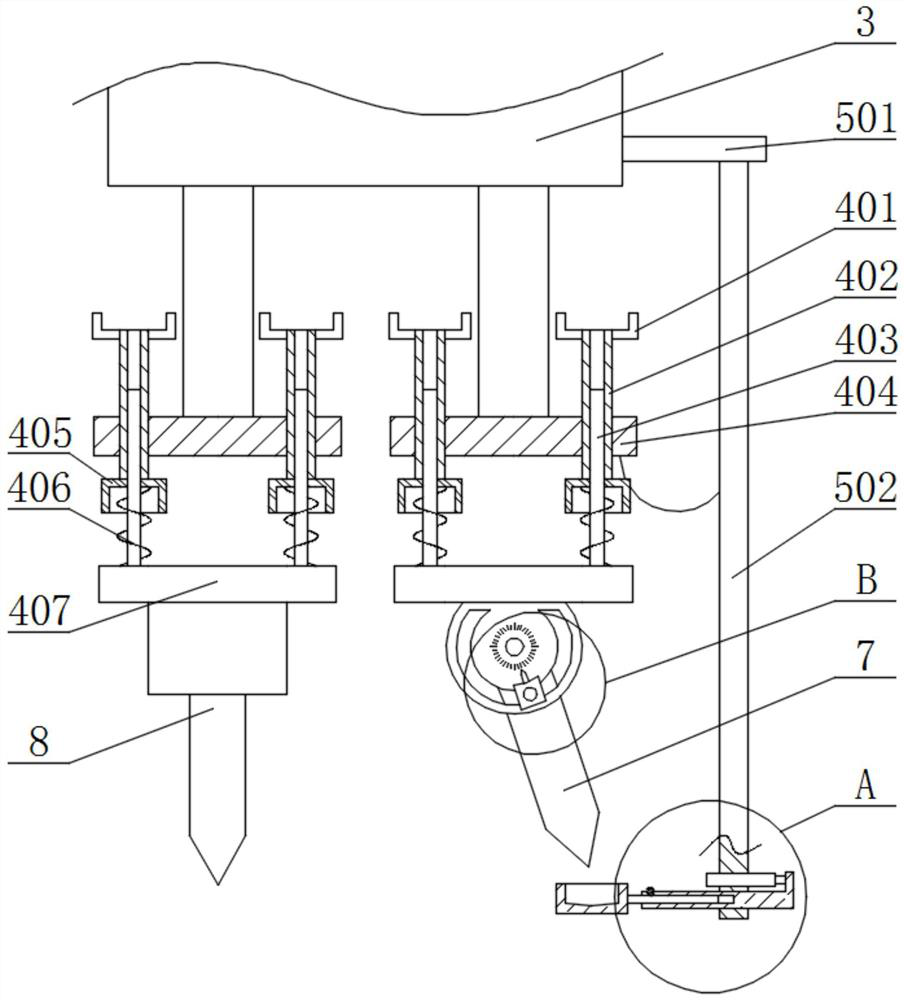

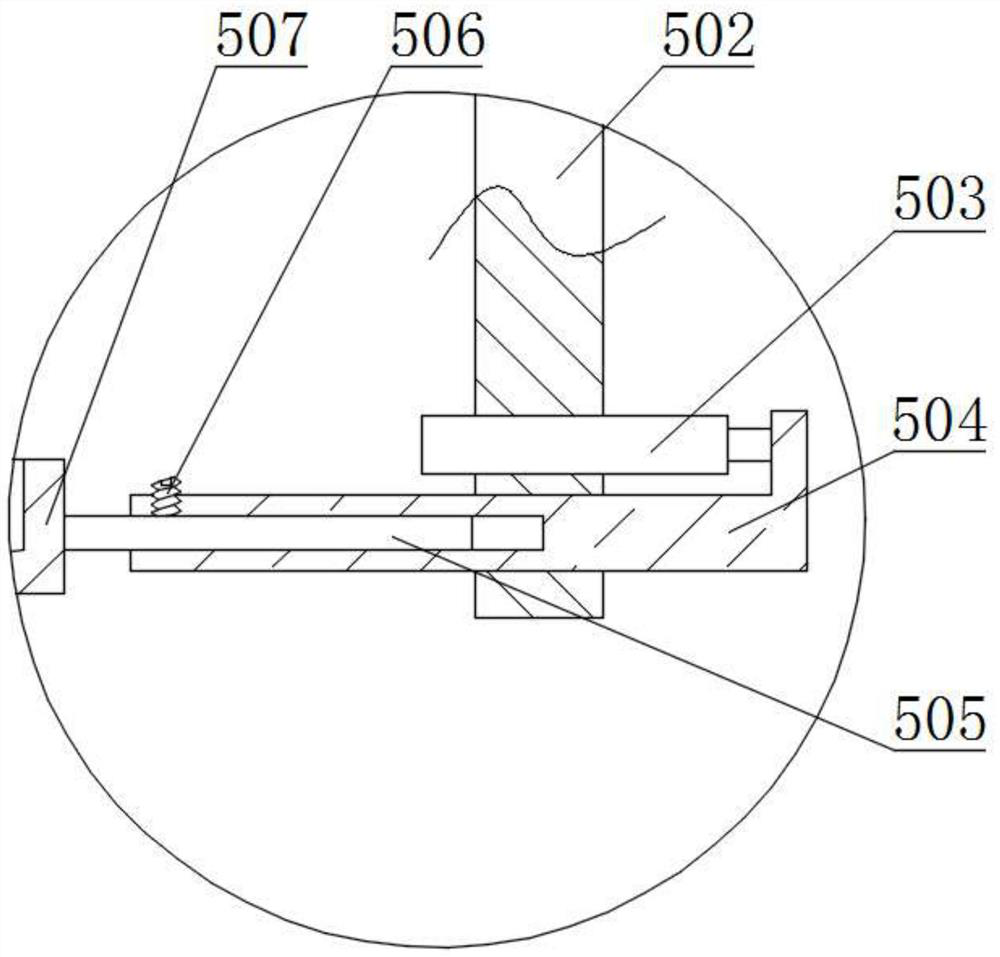

[0029] see Figure 1-6 , the present invention provides a technical solution:

[0030] A printing device for a screen printing machine and a method for using the same, comprising a printing machine main body 1 and a lifting mechanism 3, a controller 2 is fixedly connected to the front end of the printing machine main body 1, and a lifting mechanism 3 is fixedly connected to the front end of the printing machine main body 1, The bottom end of the lifting mechanism 3 is fixedly connected with a position compensation device 4, the bottom end of the position compensation device 4 on the left side is fixedly connected with an ink return plate 8, and the bottom end of the position compensation device 4 on the right side is fixedly connected with an angle adjustment device 6. One end of the angle adjustment device 6 is rotatably connected with a squeegee 7, and the right end of the lifting mechanism 3 is fixedly connected with a protective device 5, and the position compensation devi...

Embodiment 2

[0037] The same parts of Embodiment 2 and Embodiment 1 will not be repeated. The difference is that when it is necessary to use the first electric telescopic rod 409 to adjust the tension force of the spring 406, the staff controls the first electric telescopic rod 409 through the controller 2 The fixed block 408 is moved in the vertical direction while the fixed block 408 moves in the vertical direction with the connecting frame 405 through the rotating cylinder 402 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com