End cover matched with aluminum external water slot bright strip

An external water cutting and bright strip technology, applied in the direction of engine sealing, sealing device, engine components, etc., can solve the problems of easy falling, difficult to assemble the aluminum bright strip external water cutting end cover, etc., to achieve simple assembly and easy automatic assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

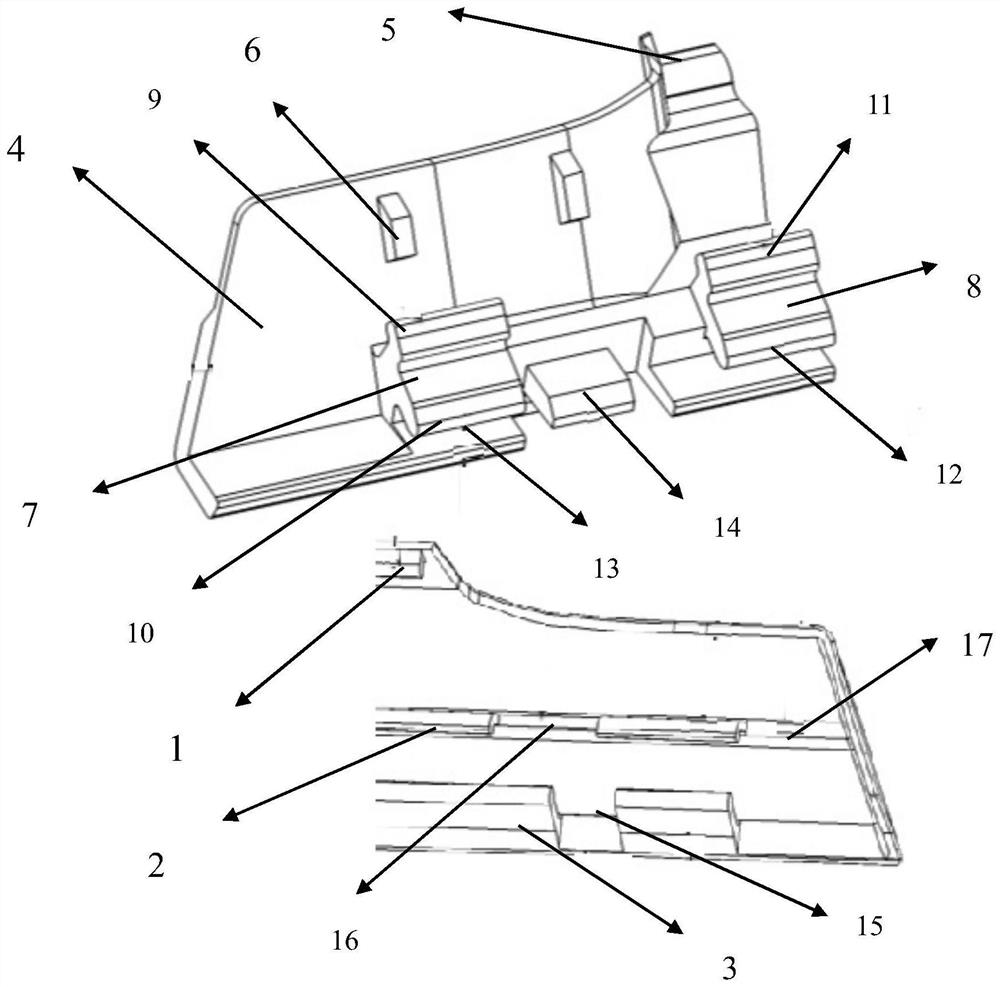

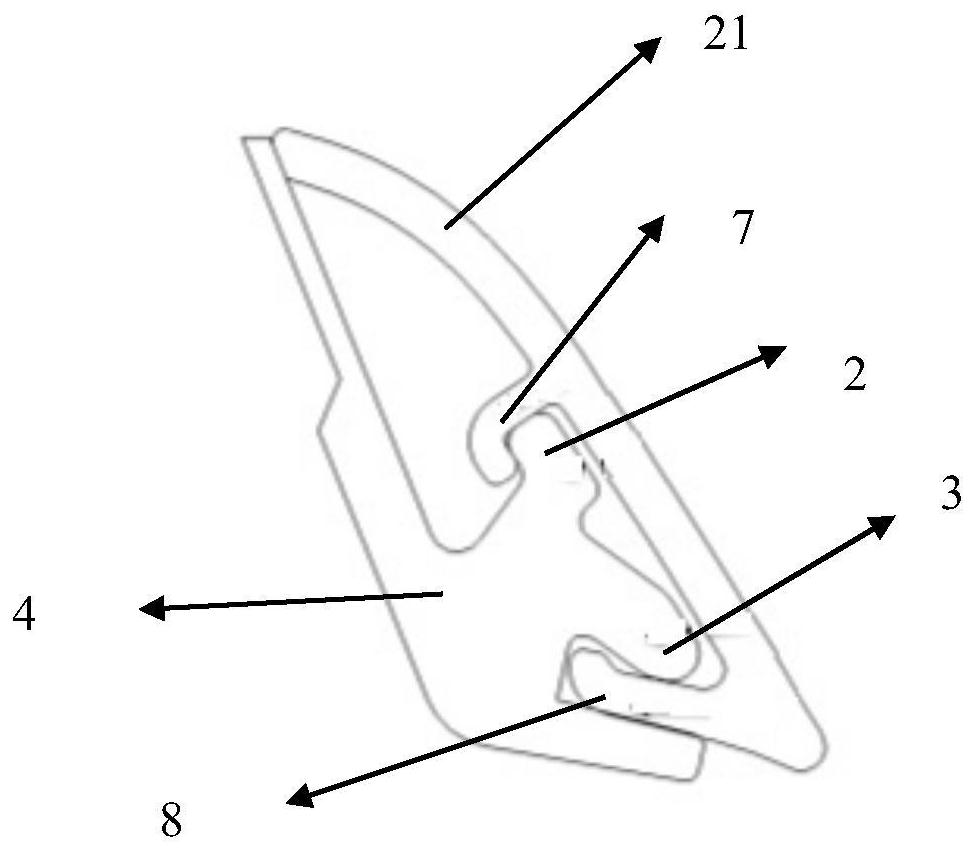

[0021] Such as figure 1 and figure 2 As shown, the end cap matched with the outer water-cut aluminum bright strip is installed at the end of the bright strip 21. The bright strip 21 has upper side rib 1, middle rib 2 and lower side rib 3. The material and mechanical properties of the aluminum bright strip can be According to customer requirements, there is no special requirement. The material of the end cover can be POM, PP-T20, ABS and other hard plastics according to customer requirements. The end cover fixing rib that is matched with the middle rib 2, the upper part of the body 4 is provided with an upper fixing rib 5, and the upper fixing rib 5 cooperates with the upper rib 1 of the bright strip 21, and the upper fixing rib 5 is located at the side end of the upper part , the inner surface of the body 4 is provided with abutment clip 6, here the bright strip 21 is supported by the abutment clip 6 to prevent the bright strip 21 from collapsing, here there are two end cove...

Embodiment 2

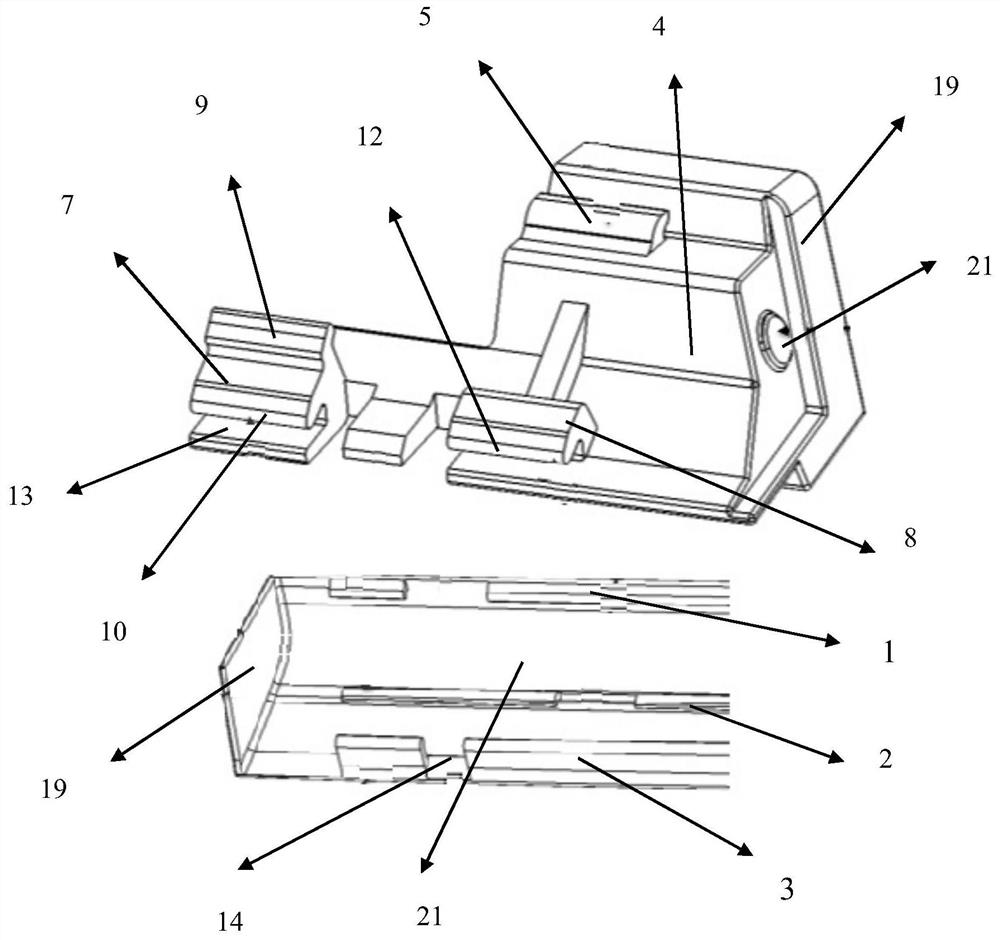

[0025] Such as image 3 , Figure 4 as well as Figure 5 As shown, most of the structure of this embodiment 2 is the same as that of embodiment 1. The end cover has a crescent gap, and there are two end cover fixing ribs, including the first end cover fixing rib 7 and the second end cover fixing rib 8, On the first end cover fixing rib 7, there is a rib 9 on the first end cover and a rib 10 under the first end cover, and the second end cover fixing rib 8 has a rib 12 under the second end cover, which is fixed on the first end cover. Elastic grooves 13 are formed on the ribs 7 and the second end cover fixing ribs 8, and the positioning limit ribs 14 are located between the first end cover fixing ribs 7 and the second end cover fixing ribs 8, and the end cover has a flanging support edge 18 , there is a flanging 19 on the bright strip 21, and an end cap positioning boss 20 on the body 4, the flanging supporting edge 18 is located inside the flanging 19, and the end cap positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com