Pressure self-unloading type hot water tank based on chemical production

A technology for chemical production and hot water tanks, applied in containers, packaging, transportation and packaging, etc., which can solve the problems of low pressure outside the tank, limited speed of pressure relief, difficult control of steam output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Embodiment:

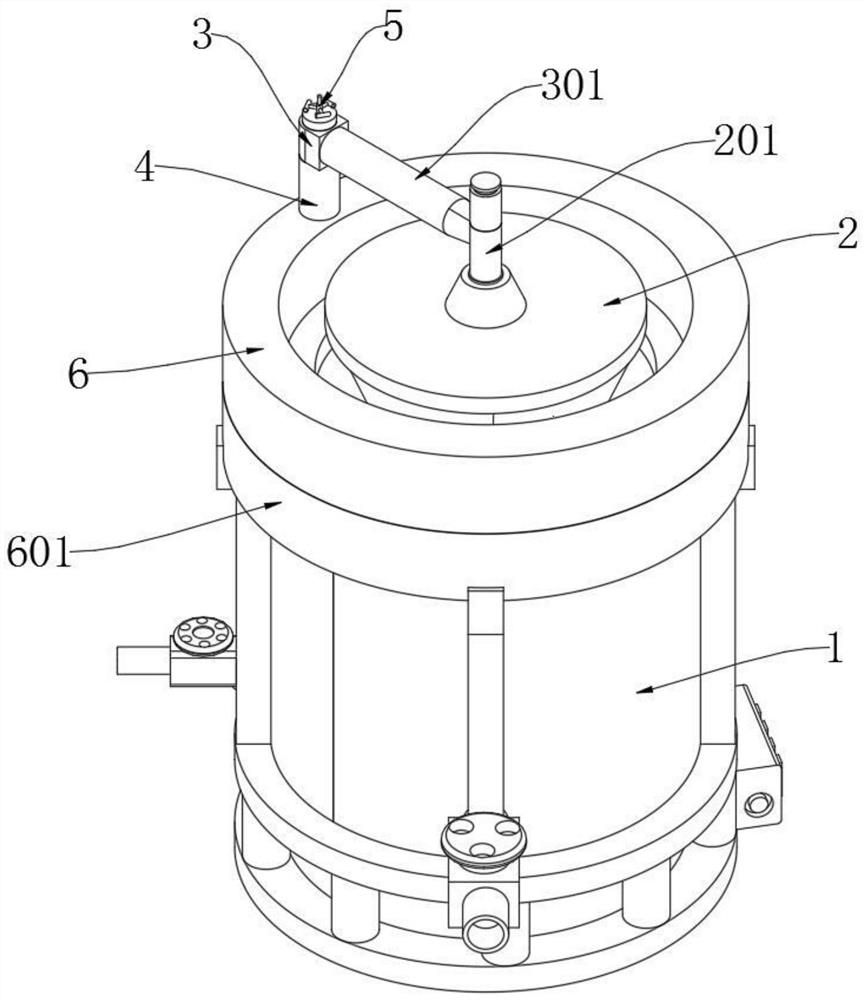

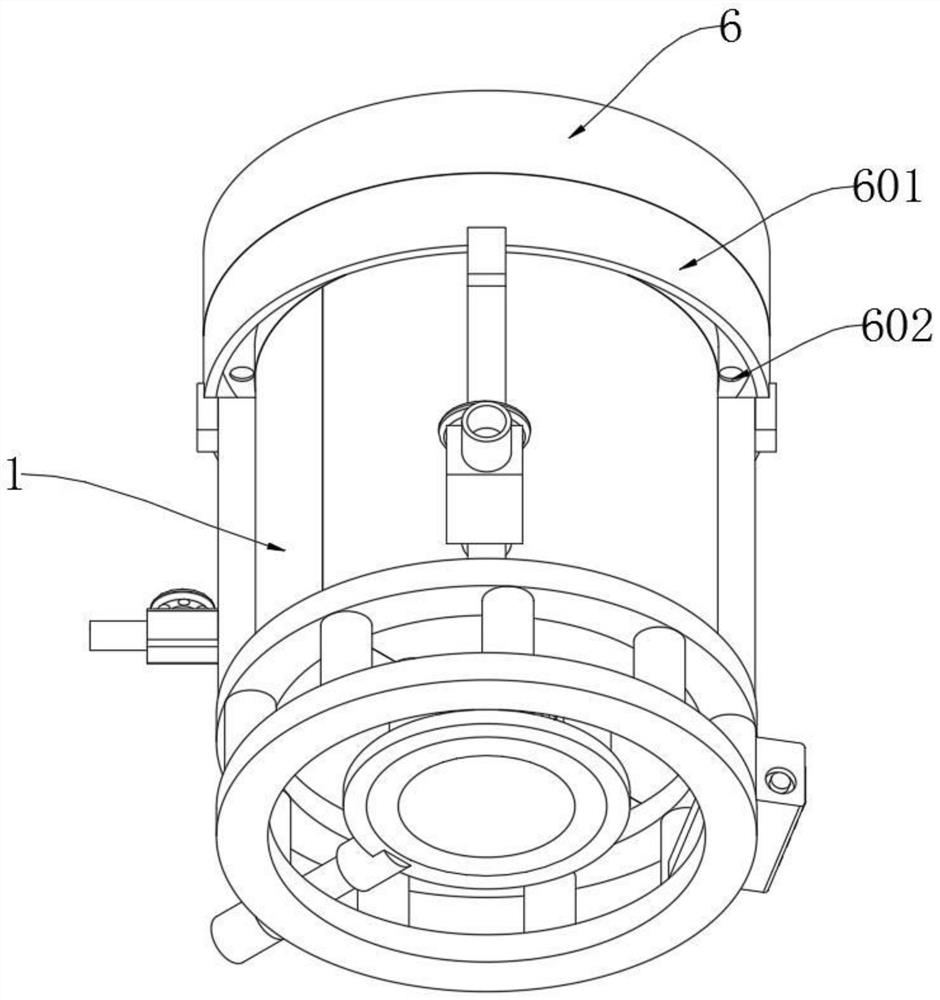

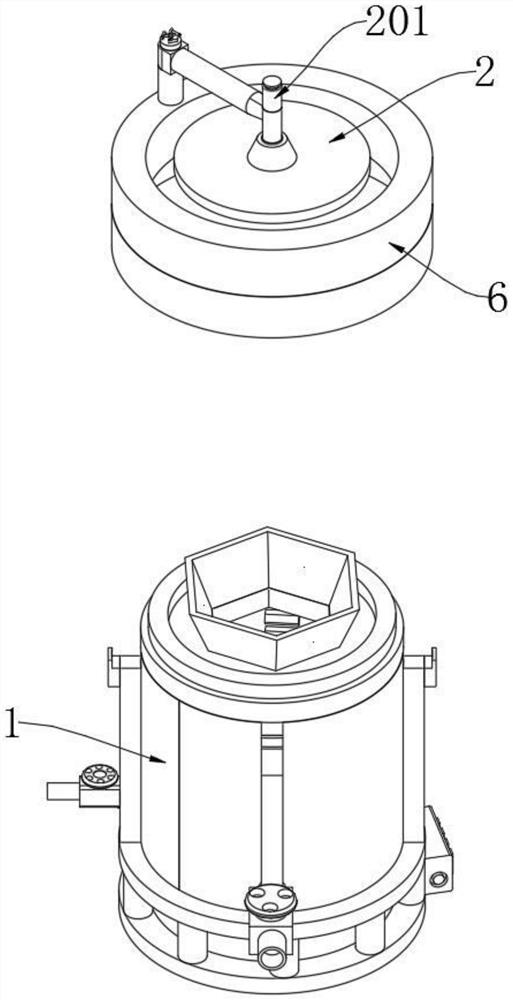

[0035] Append figure 1 Attachment Figure 8 Looking:

[0036]The present invention provides a chemical dumping mechanism 2 including a hot water tank body 1, a hot water tank body 1, a disk-shaped top seal mechanism 2, a top seal mechanism 2 includes an top seal. The tube 201, the ring 202, and the interior of the interface 203, the central portion of the top plane of the top seal mechanism 2 is fixedly mounted, and the pressure pipe 3 is discharged vertically in the upper left end of the top seal tube 201, in the top of the tube 201 A rectangular pair interface 203 is opened at a position opposite to the pressure relief tube 3, and a ring-shaped ring 202 is fixed in the inner pipe 201 in the interface 203, and the lower end of the dumping mechanism 7 is attached. Then, on the ring 202; the central portion of the upper end of the top of the top seal mechanism 2 is vertically left to the left, and the left end of the pressure relief tube 3 fixes the vertically d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap