Comb-type slideway electric dragging winch group self-adaptive synchronous control system and method

A synchronous control and self-adaptive technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of out-of-synchronization of motors, affecting the safety of ships, and high cost of large longitudinal berths, achieving stable rope speed and automatic control efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

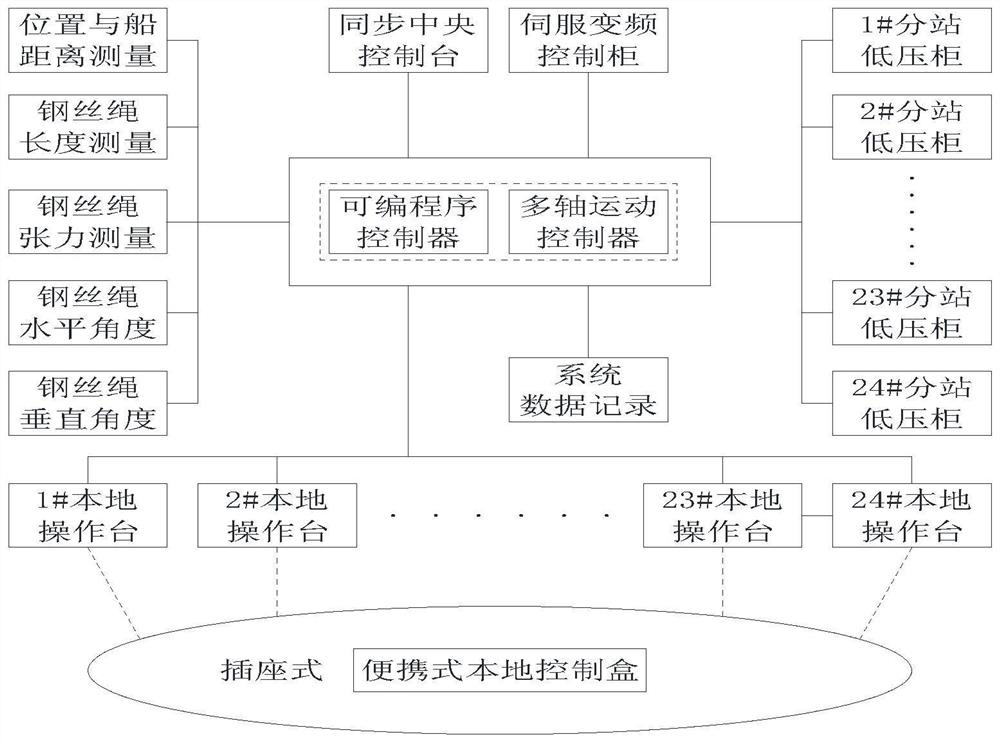

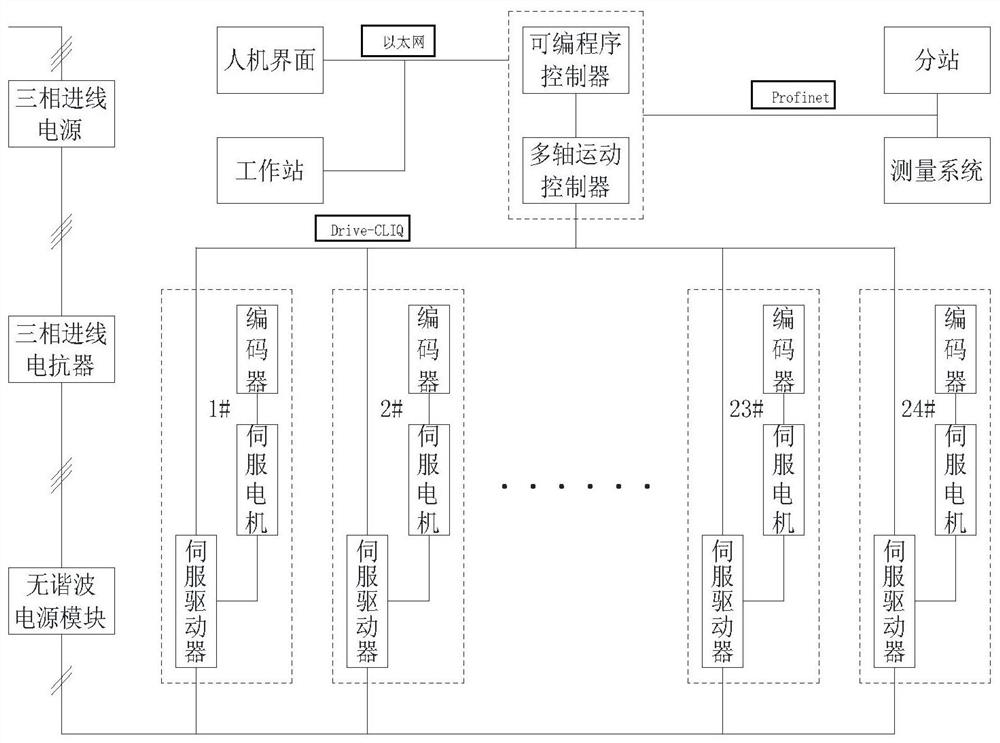

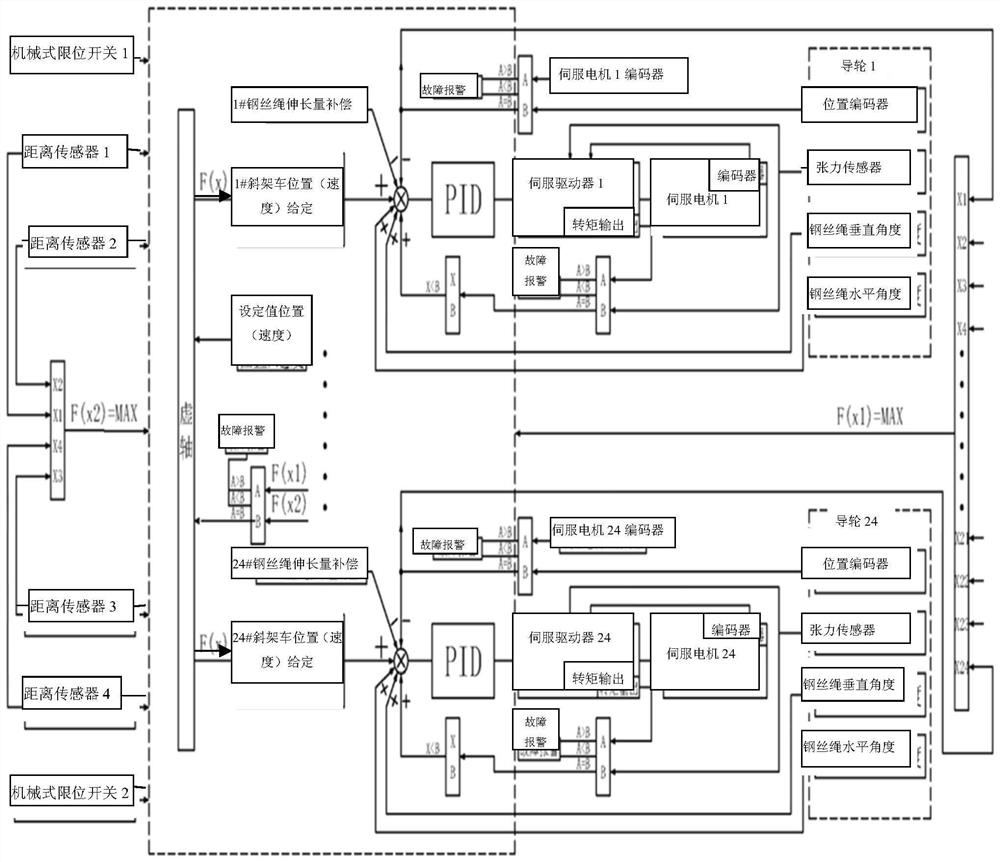

[0032] Embodiment 1, in the first aspect, the present invention provides an adaptive synchronous control system for comb-type slideway electric drag winch group, such as figure 1 As shown, it includes multi-axis motion controller, sensor detection system, system center console, data recording system, operation box and 24 winch modules; the operation box is a portable local control box. 24 winch modules are used to tow the ship to pier or launch; the multi-axis motion controller is integrated with a programmable controller; 24 winch modules correspond to 24 local consoles, and each local console corresponds to a local substation Low-voltage cabinet; 24 winch modules are respectively connected to the multi-axis motion controller; sensor detection system, data recording system, local console, system center console, and local substation low-voltage cabinet are respectively connected to the multi-axis motion controller. Each local console is provided with an operation box interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com