Rail transit elevated sound barrier

A technology for rail transit and overhead sound, which is applied in lighting and heating equipment, construction, cleaning methods, etc., and can solve problems such as dust removal and inability to ventilate through sound barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

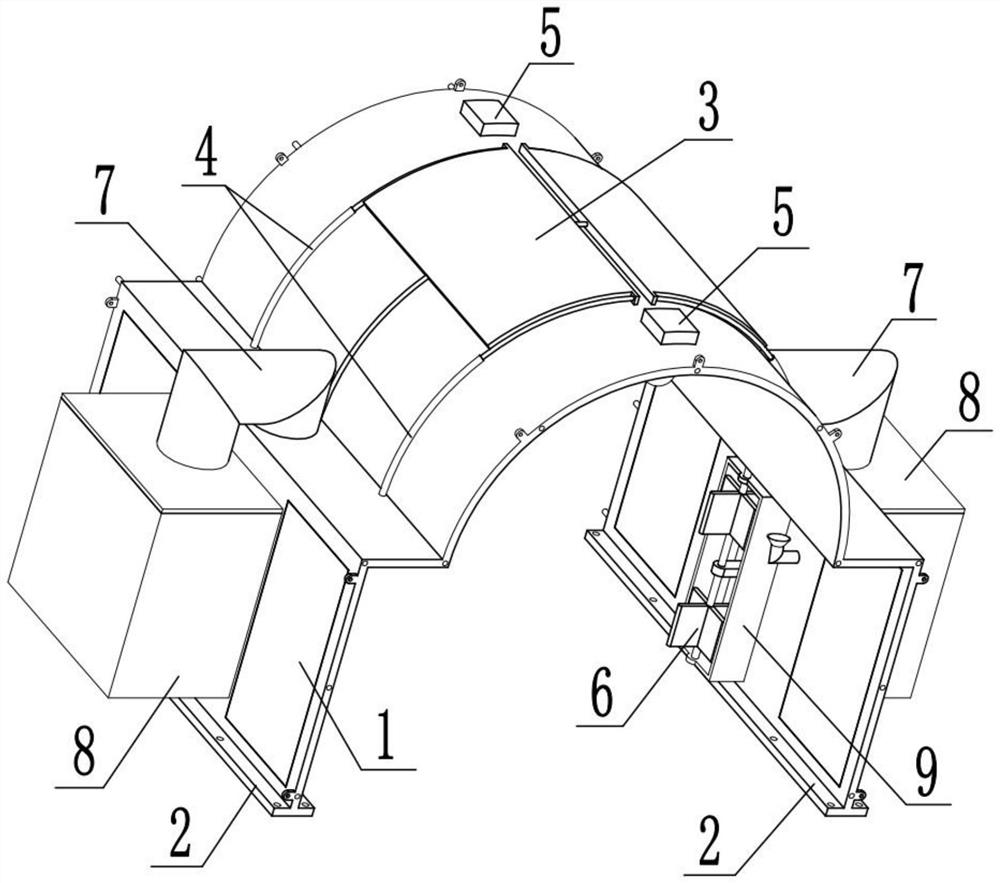

[0033] Combine below Figure 1-11 Describe this embodiment, the present invention relates to the technical field of sound barriers, more specifically, an elevated sound barrier for rail transit, including an elevated sound barrier component 1, a fixed connection base device 2, a curved surface recovery ventilation device 3, and a recovery telescopic connection device 4 , solar lighting device 5, rotating dust absorbing device 6, dust transfer pipe member 7, dust absorbing storage device 8 and shielding frame body 9, can connect a plurality of this devices together and be fixed on the both sides of track, allow a plurality of fixed The posts 1-7 are respectively slidably connected in a plurality of fixed sockets 1-6 adjacent thereto, and then a plurality of adjacent connecting seats 1-5 are used to fix two adjacent devices together to form a long Sound barrier, and the air in the long sound barrier may not be very good, so you can move two shielding curved plates 3-2 to expose th...

specific Embodiment approach 2

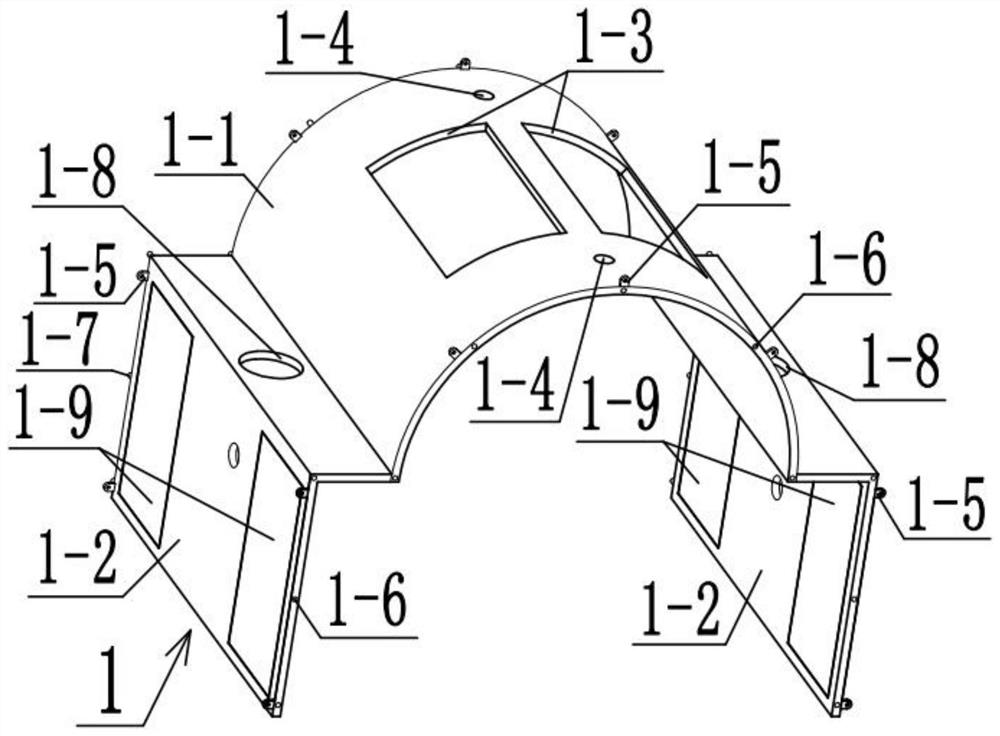

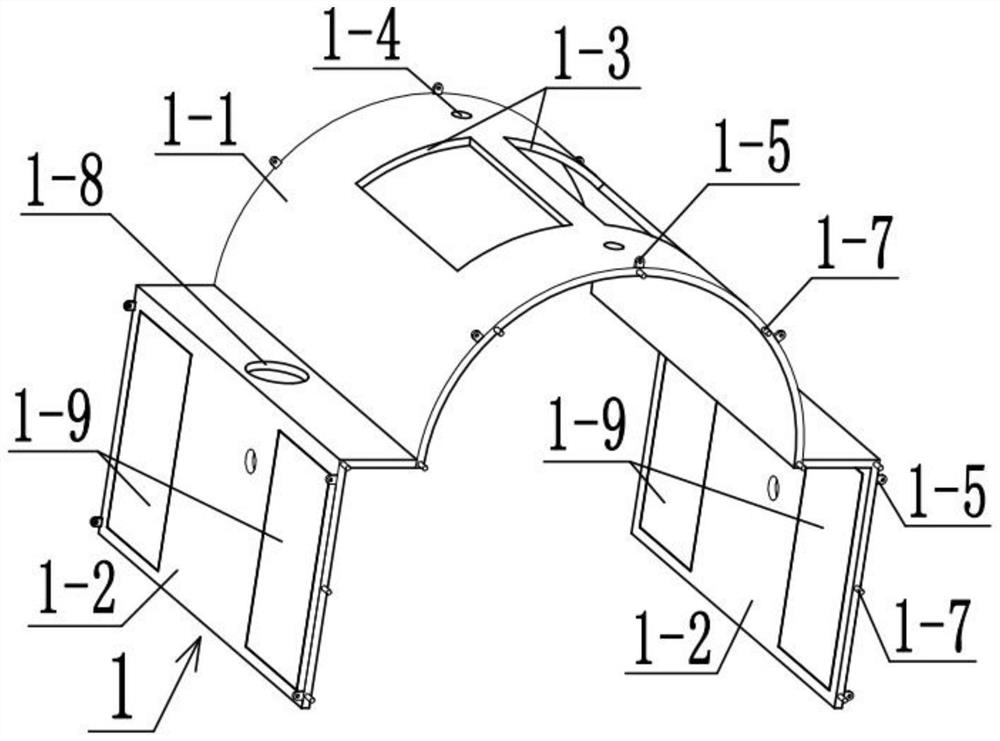

[0036] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain Embodiment 1. The elevated sound barrier component 1 includes a semi-arched plate 1-1, a vertical sound barrier plate 1-2, a ventilation port 1-3, and a lighting hole 1-4 , connecting seat 1-5, fixed socket 1-6, fixed post 1-7, dust suction hole 1-8 and light-transmitting window 1-9, and the semi-arched plate 1-1 plays the role of shielding and noise reduction, Both sides below the semi-arched plate 1-1 are fixedly connected with a vertical sound barrier plate 1-2, and the vertical sound barrier plate 1-2 plays the role of bearing connection and can also reduce noise. The semi-arched plate 1 Both ends above -1 are provided with air vents 1-3, after the air vents 1-3 are provided, the air in the device can be ventilated to ensure that the device will not be stuffy. There are two lighting holes 1-4, and the two lighting holes 1-4 can provide space for the fixed lamp holder 5-2 to pa...

specific Embodiment approach 3

[0038] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the fixed connection base device 2 includes the anchor plate 2-1 and the anchor hole 2-2, the anchor plate 2-1 plays the role of load-bearing connection, A plurality of anchor holes 2-2 are arranged on the anchor plate 2-1, so that a plurality of fixing bolts respectively pass through a plurality of anchor holes 2-2 and are connected under the ground, so that the device can be fixed on the ground, There are two fixedly connected base devices 2, and the two anchor plates 2-1 are respectively fixedly connected under the two vertical sound barrier plates 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com