Foundation construction method capable of achieving surface soil on-site solidification and pile combined bearing

A construction method and topsoil technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problem of pile body being prone to skew, and achieve the effect of increasing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-6 The application is described in further detail.

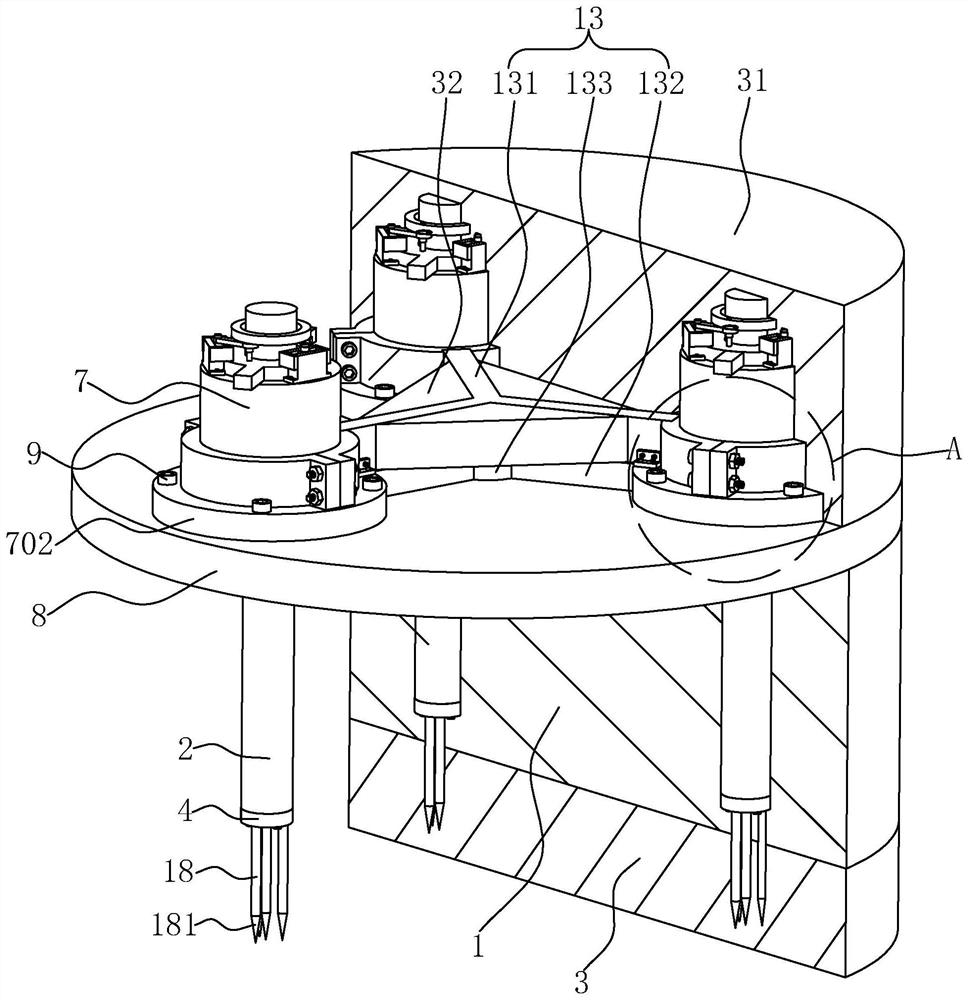

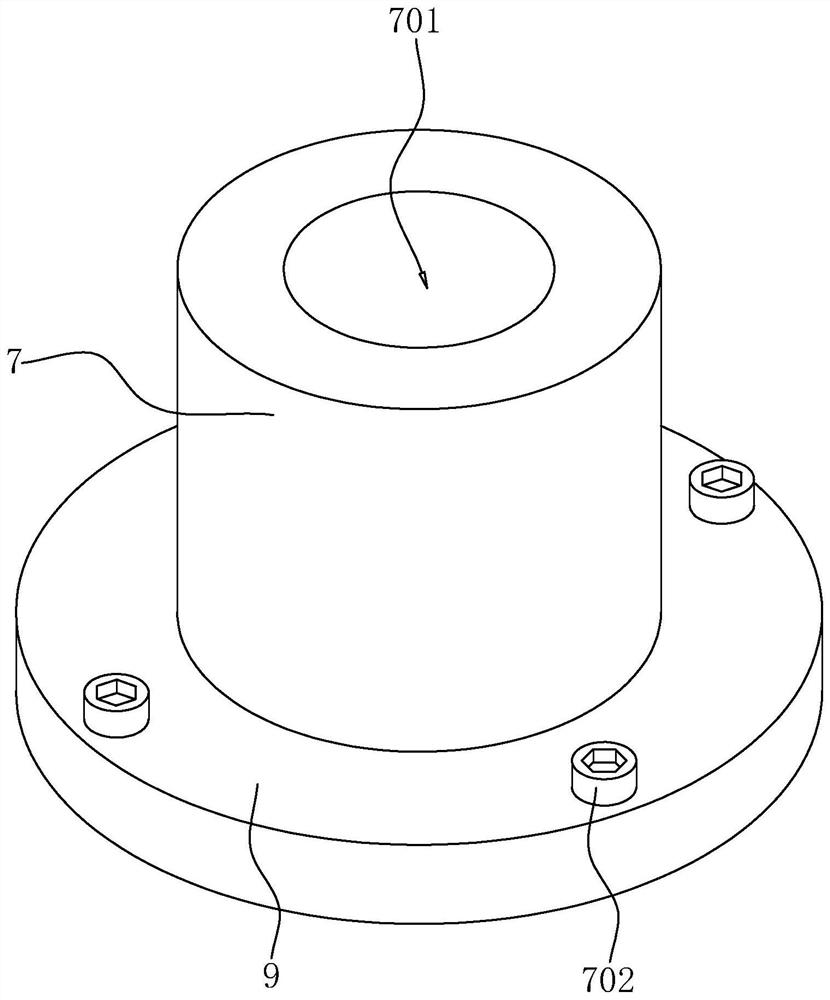

[0044] The embodiment of the present application discloses a foundation structure in which surface soil is solidified in situ and combined with piles. refer to figure 1 , the foundation structure includes several piles 2 inserted in the in-situ soil layer 1 and uprights 7 for fixing the piles 2, the top of the uprights 7 is fixedly provided with a clamping mechanism for clamping uprights 7 and for connecting uprights 7 brackets 13 .

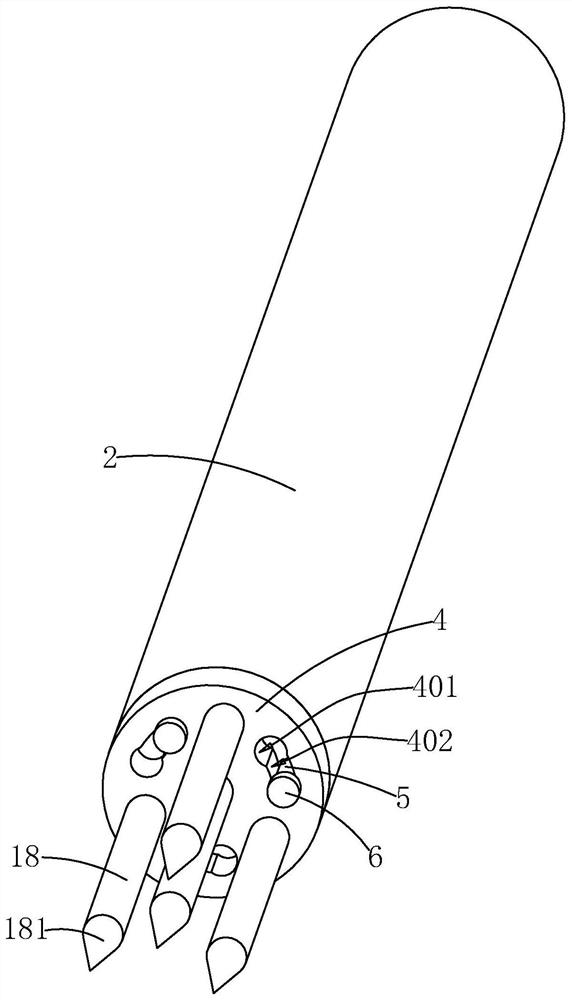

[0045] refer to figure 1 and figure 2 , in this embodiment, the number of piles 2 is three, and the three piles 2 are arranged vertically, and the three piles 2 are distributed in an equilateral triangle. The bottom end of the pile body 2 is fixedly provided with an installation block 4, and the lower surface of the installation block 4 is welded with several insertion rods 18. The lower surface of the in-situ soil layer 1 is the bearing layer 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com