Steel structure scaffold

A technology for scaffolding and steel structures, applied in the field of steel structure scaffolding, can solve problems such as troublesome, time-consuming manpower, inability to adjust length and width, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

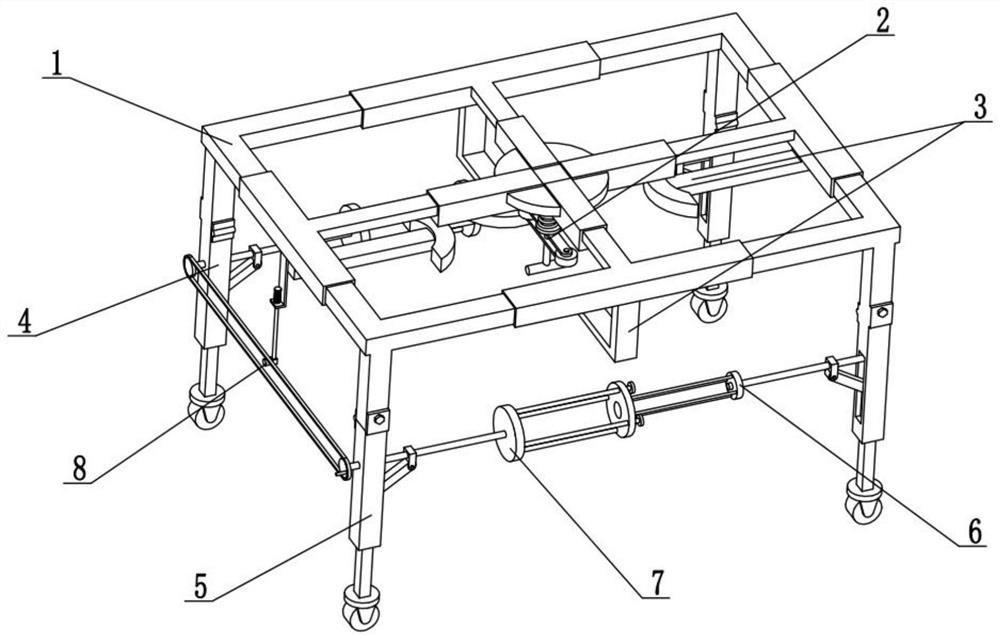

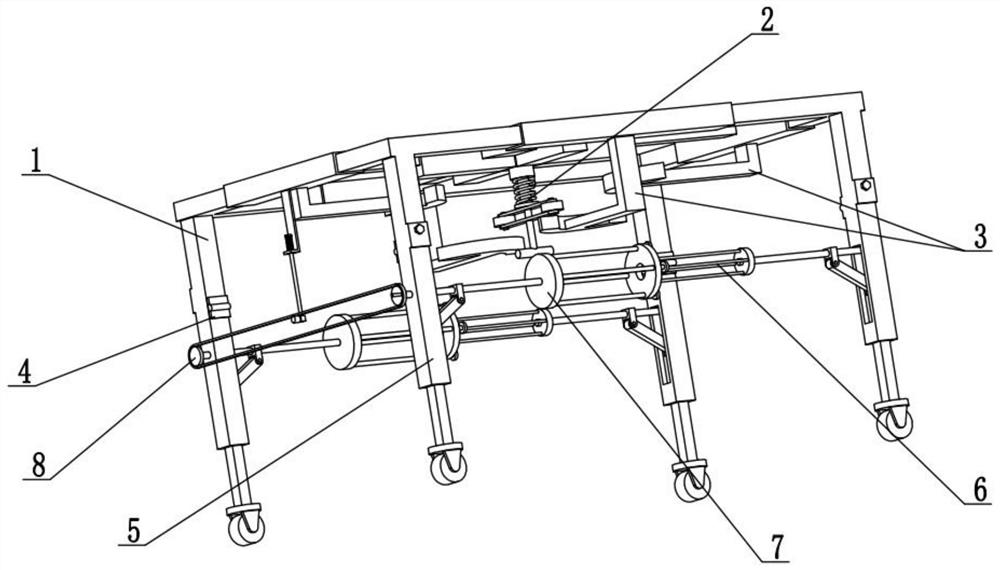

[0029] Combine below Figure 1-10 Describe this embodiment, the present invention relates to the technical field of construction, more specifically a steel scaffolding, including a telescopic frame 1 on the top surface, an extension and rotation mechanism 2, a suspension matching push rod 3, adjustable short legs 4, adjustable Long leg 5, follow-up rotating arm 6, adjustable active beam 7 and lifting linkage mechanism 8, the adjustable short leg 4 and the adjustable long leg 5 are all provided with two, two adjustable short legs 4 are respectively hinged to the left and right ends of the rear end of the top telescopic frame 1, and the two adjustable long legs 5 are respectively hinged to the left and right ends of the front end of the top telescopic frame 1, and the extension rotation mechanism 2 is fixedly connected to the bottom of the top telescopic frame 1 end, there are four suspension matching push rods 3, and the four suspension matching push rods 3 are all fixedly conn...

specific Embodiment approach 2

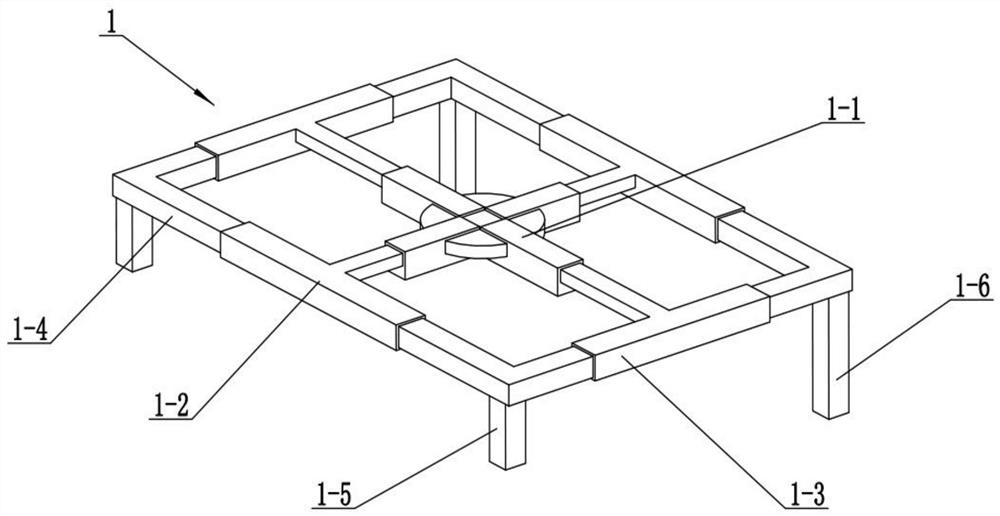

[0032] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the top telescopic frame 1 includes a cross slide 1-1, a front and rear moving sleeve 1-2, a left and right moving sleeve 1-3, and a right-angle sliding beam 1-4, short connecting legs 1-5 and long connecting legs 1-6, two front and rear moving sleeves 1-2 are respectively slidably connected to the front and rear ends of the cross slideway 1-1, two left and right moving sleeves 1- 3 are respectively slidably connected to the left and right ends of the cross slideway 1-1, and the two ends of the four right-angled sliding beams 1-4 are respectively slidably connected to two left and right moving sleeves 1-3 and two front and rear moving sleeves 1-2 Inside, the two short connecting legs 1-5 are respectively fixedly connected to the bottom ends of the two right-angle sliding beams 1-4 at the front end, and the two long connecting legs 1-6 are respectively fixedly ...

specific Embodiment approach 3

[0035] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the second embodiment, the extension and rotation mechanism 2 includes a hollow cylinder 2-1, a sliding pole 2-2, a tension spring 2-3, a horizontal beam 2-4, Pushing auxiliary wheels 2-5 and rotating handle 2-6, rotating handle 2-6 is fixedly connected to the bottom of horizontal beam 2-4, pushing auxiliary wheels 2-5 is provided with two, two pushing auxiliary wheels 2- 5 respectively rotate and connect to the front and rear ends of the horizontal beam 2-4, the sliding vertical rod 2-2 is fixedly connected to the horizontal beam 2-4, the sliding vertical rod 2-2 is slidingly connected in the hollow cylinder 2-1, and the hollow circle The cylinder 2-1 is fixedly connected to the bottom of the cross slideway 1-1, and a tension spring 2-3 is fixedly connected between the hollow cylinder 2-1 and the horizontal beam 2-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com