An integrated short connector for drilling tools

A technology of drilling equipment and connectors, which is applied in the direction of drilling pipes, drill pipes, earthwork drilling, etc., can solve the problems of high risk of connection safety, easy breakage of cables, and inconvenience of drilling construction, and achieve the requirements of simplifying on-site operations, The instrument matching operation is simple and the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

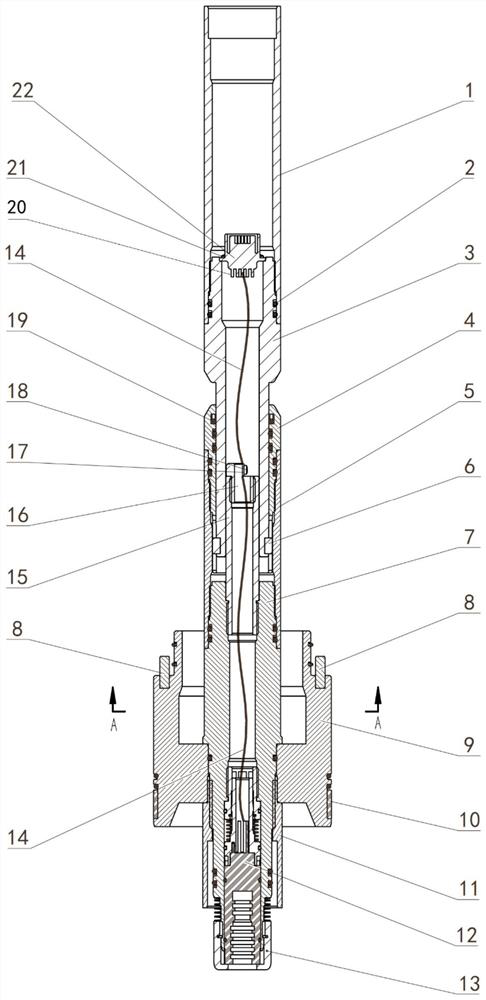

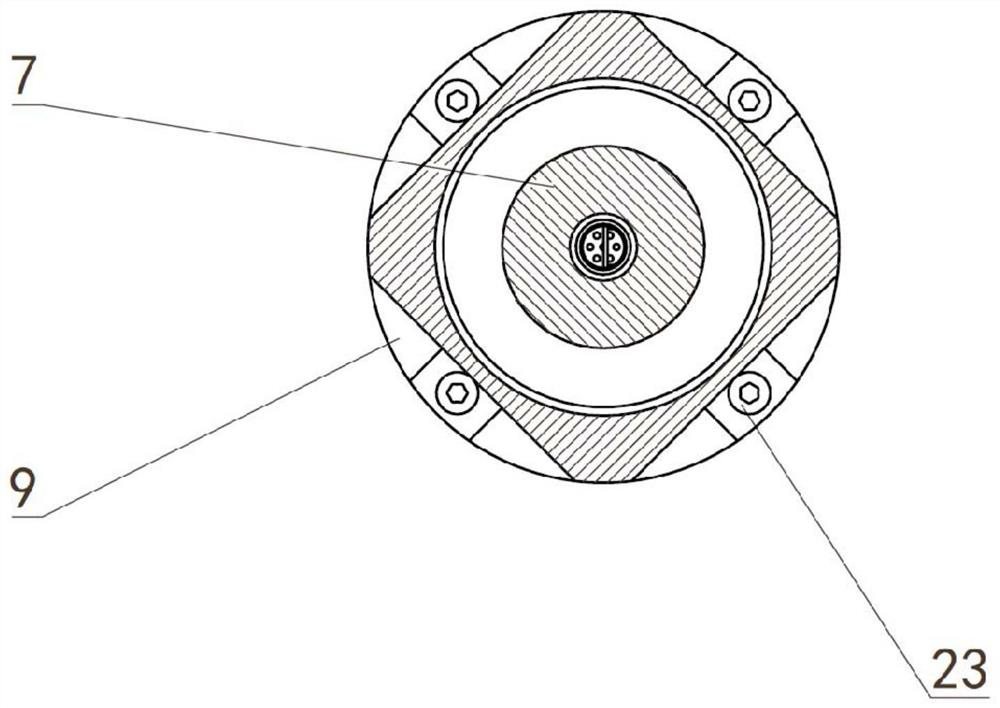

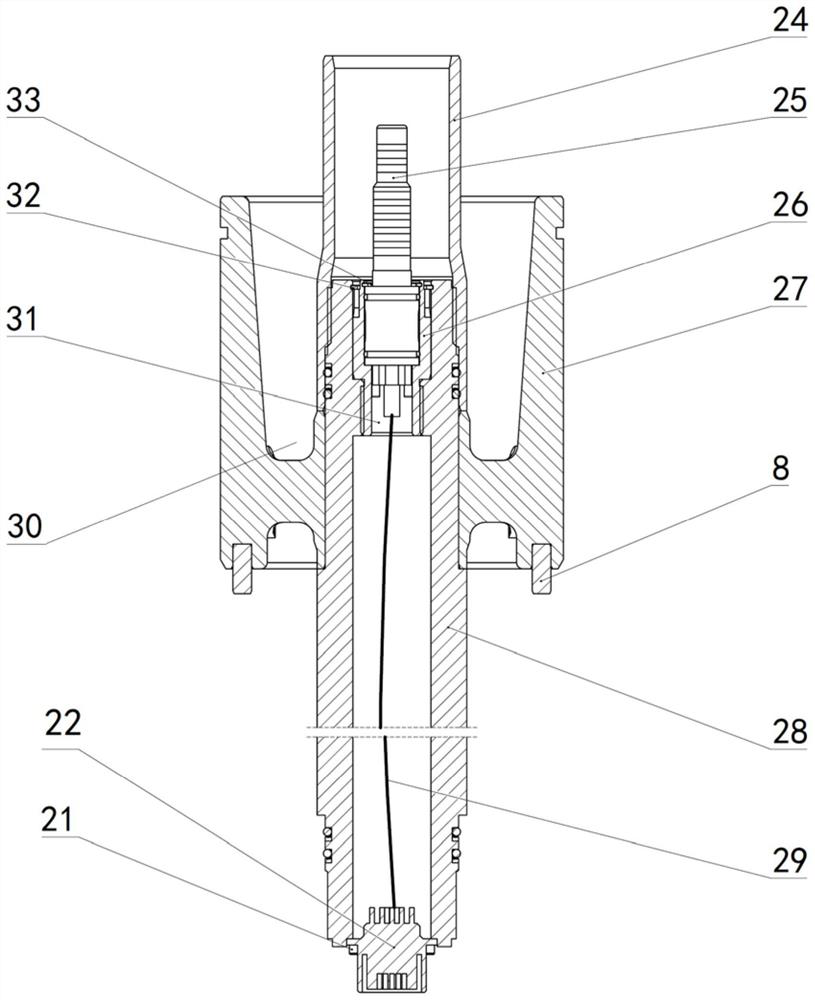

[0029] Below in conjunction with accompanying drawing, the present invention is further described:

[0030] see Figure 1 to Figure 6 , a tool-while-drilling integrated short connector, including a telescopic connector assembly, a fixed connector assembly and a drill collar adapter; the drill collar adapter includes an upper drill collar adapter 44 and a lower drill collar adapter 45. The connector assembly is installed in the upper drill collar adapter, the fixed connector assembly is installed in the lower drill collar adapter; the telescopic connector assembly and the fixed connector assembly are butted; the telescopic connector assembly is installed in the upper drill collar In the conversion joint, the fixed connector assembly is installed in the lower drill collar joint, and the upper and lower drill collar conversion joints directly drive the docking of the internal connectors. The inter-node communication and power supply bridge are more stable in the downhole, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com