Fan

A fan and shroud technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of complex assembly process, many parts and high cost, and achieve simple assembly process, few parts and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

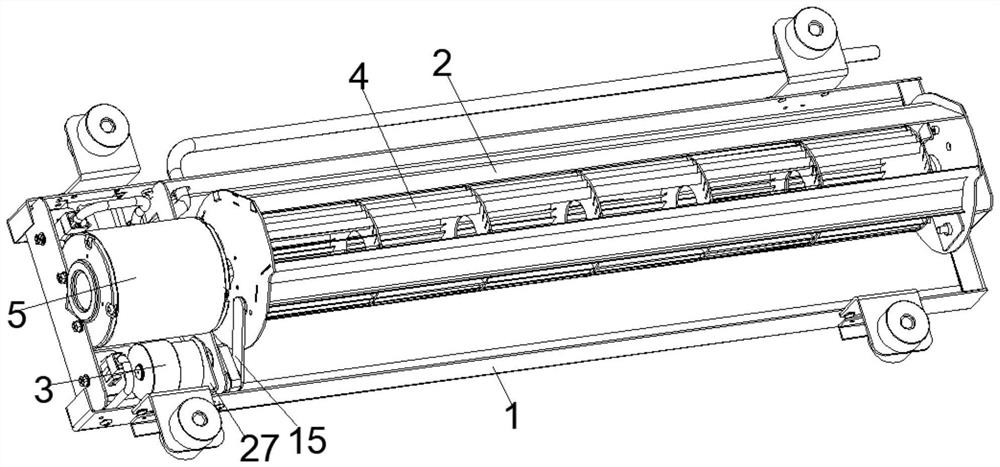

[0038] This embodiment provides a fan, which includes a frame 1, a wind deflector 2, a first motor 3, a blade assembly 4 and a second motor 5, wherein the first motor 3, the second motor 5 and the wind deflector 2 are installed on the frame 1, and the connection between the above-mentioned wind deflector 2 and the frame 1 is a rotational connection, and the wind deflector 2 is connected with the rotating shaft of the above-mentioned first motor 3, and the first motor 3 can drive the wind deflector 2 swings, the above-mentioned fan blade assembly 4 is arranged inside the wind deflector 2, the rotating shaft of the second motor 5 is connected with the blade assembly 4, and the second motor 5 will rotate inside the wind deflector 2 to generate wind when the second motor 5 is energized and running. The wind flows out of the blower fan after being diverted by the shroud 2 .

[0039] Specifically, a bearing seat 6 is installed on the side wall of the above-mentioned wind deflector 2...

Embodiment 2

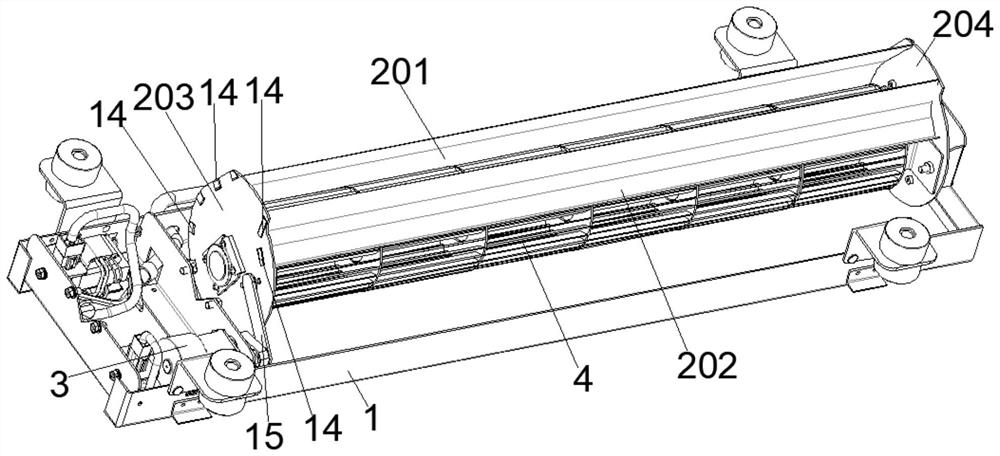

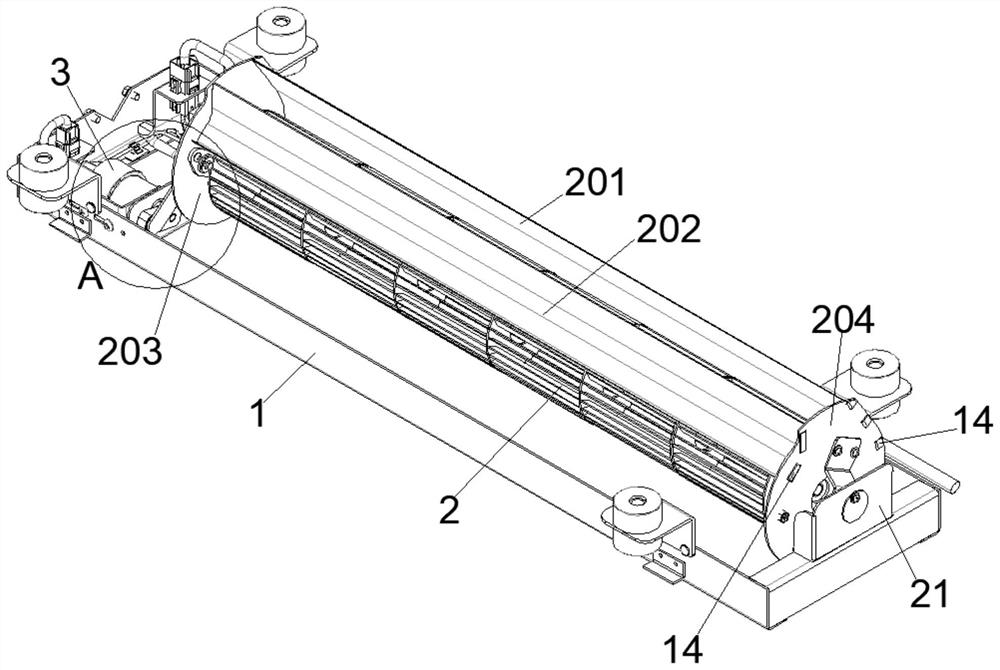

[0042] This embodiment serves as a specific implementation of Embodiment 1. In this embodiment, the above-mentioned wind deflector 2 includes a first wind deflector 201, a second wind deflector 202, a left side plate 203 and a right side plate 204, wherein , one end of the first deflector 201 and one end of the second deflector 202 are connected to the left side plate 203, the other end of the first deflector 201 and the other end of the second deflector 202 are connected to the right On the side plate 204, that is, the first deflector 201 and the second deflector 202 are connected between the left side plate 203 and the right side plate 204, and the first deflector 201 and the second deflector 202 are spaced apart. Set, the wind generated when the fan blade assembly 4 rotates is blown out from the gap between the first deflector 201 and the second deflector 202, when the first motor 3 drives the deflector 2 to swing as a whole, the above gap Rotate to control the wind directi...

Embodiment 3

[0045] This embodiment is used as a specific implementation of the embodiment. The fan provided by this embodiment also includes a first L-shaped plate 8, a second L-shaped plate 9 and a connecting plate 10, wherein the first L-shaped plate 8 and the second L-shaped plate 8 The pattern plate 9 is set away from, and the above-mentioned connection plate 10 is a flat plate, and the connection plate 10 is connected between the above-mentioned first L-shaped plate 8 and the second L-shaped plate 9. At this time, the above-mentioned first L-shaped plate 8, the connection plate 10 And the second L-shaped plate 9 forms a middle raised plate-like structure, and the above-mentioned first L-shaped plate 8 is detachably fixedly connected to the left side wall of the above-mentioned right side plate 204 by the first screw 11, and, in this The left side wall of right side plate 204 is also provided with column 12, and this column 12 protrudes left side wall of right side plate 204 toward the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com