End compensation rolling bearing with self-adaptive elimination of internal and external ring and ball clearance

A technology of rolling bearings and inner and outer rings, which is applied in the field of end compensation rolling bearings, can solve the problems of reducing support frictional resistance, reducing friction, and the impact of efficient use of bearings, and achieves the effects of accelerating air flow, improving cooling effects, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

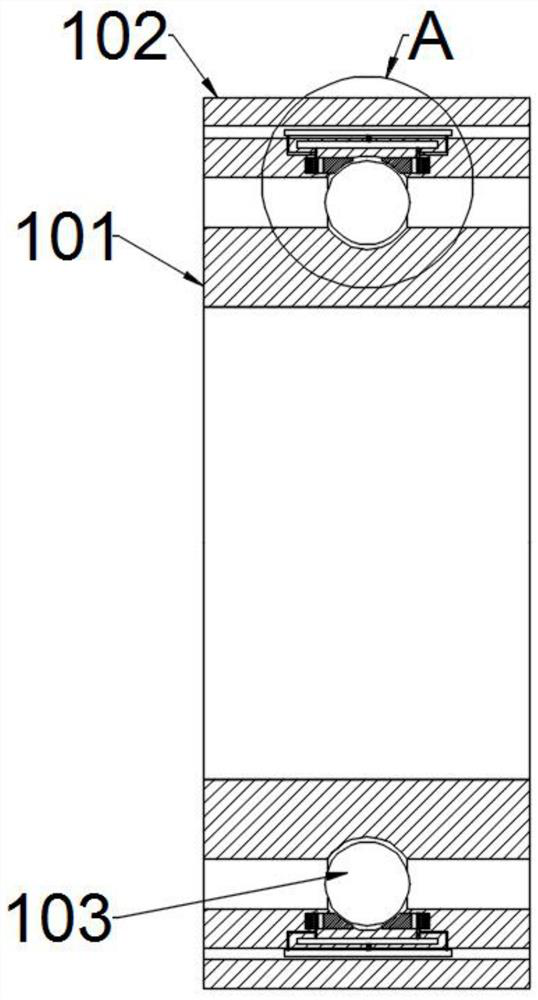

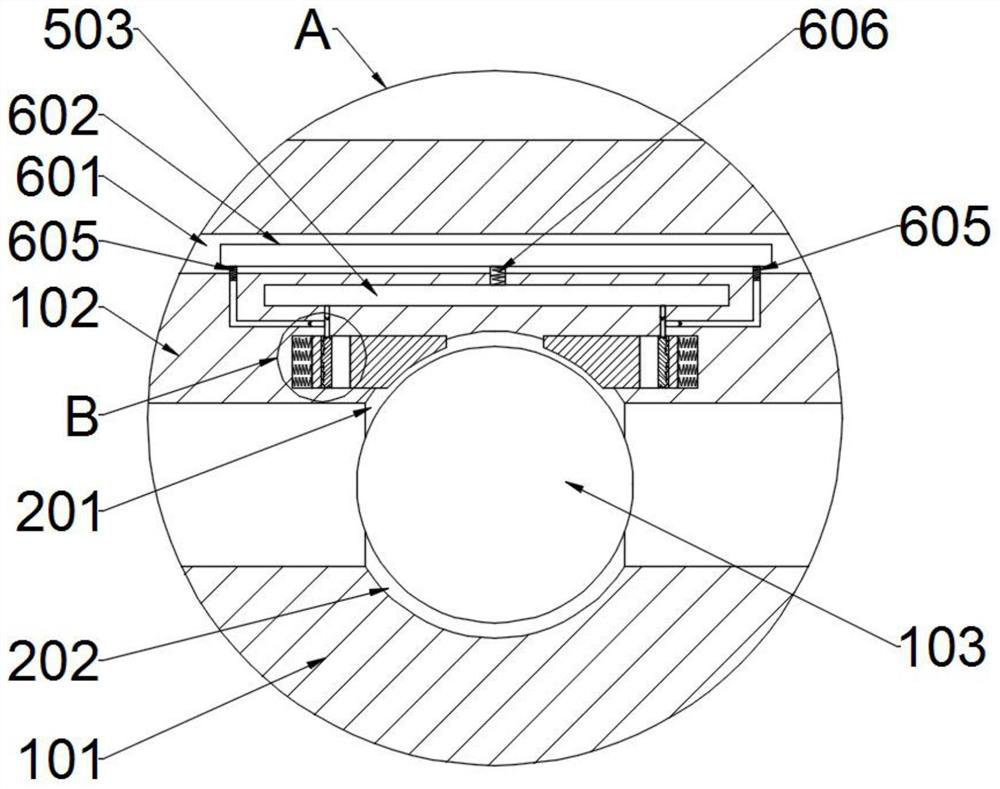

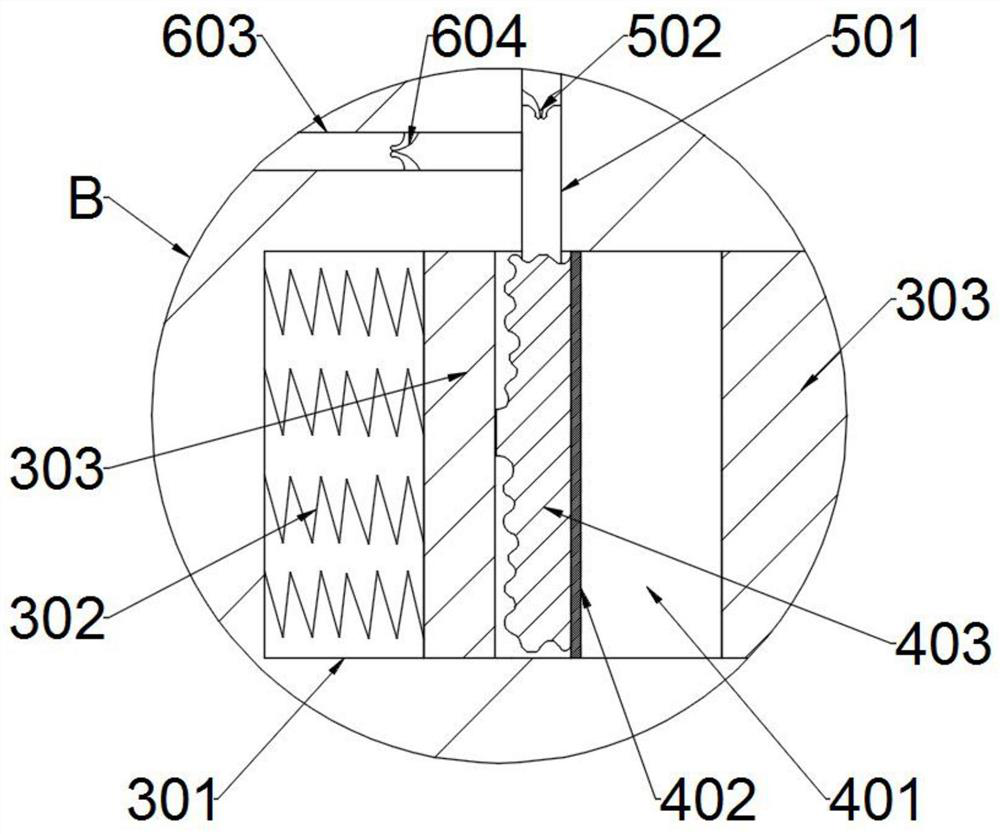

[0024] Example: such as Figure 1-5 As shown, the end-compensated rolling bearing with self-adaptive elimination of inner and outer rings and ball clearance includes basic components, limit components, clearance elimination components, elimination control components, oil inlet components, oil outlet heat dissipation components, and the basic components are located at the end of the whole set. The outer side is the main component of the bearing. The limit component is installed inside the basic component. The limit component plays a role in preventing the balls from falling. The side of the limit component is equipped with a clearance elimination component. The role of clearance, the clearance elimination component is equipped with an elimination control component, which plays a role in regulating the clearance elimination component, and the side of the elimination control component is provided with an oil inlet component, which controls the elimination regulation The effect of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com