New energy motor shell positioning gripper

A motor housing and new energy technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of poor motor housing grabbing effect and inaccurate positioning grabbing, and achieve grabbing effect. Good, high grabbing efficiency, easy grabbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

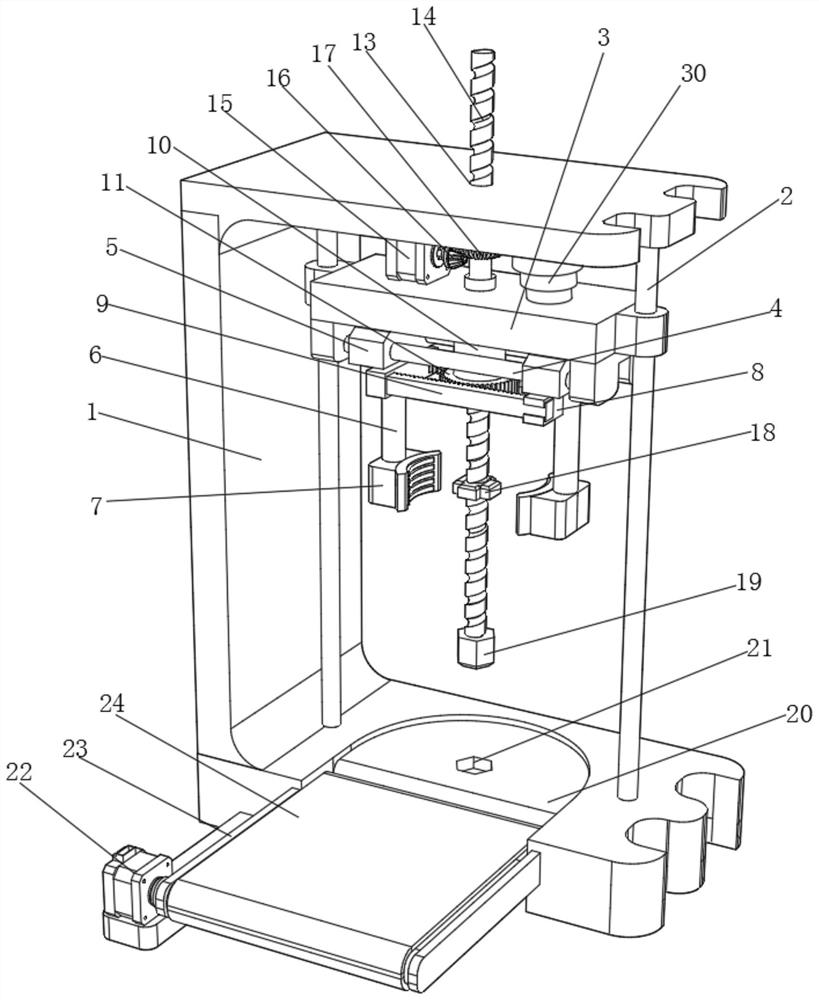

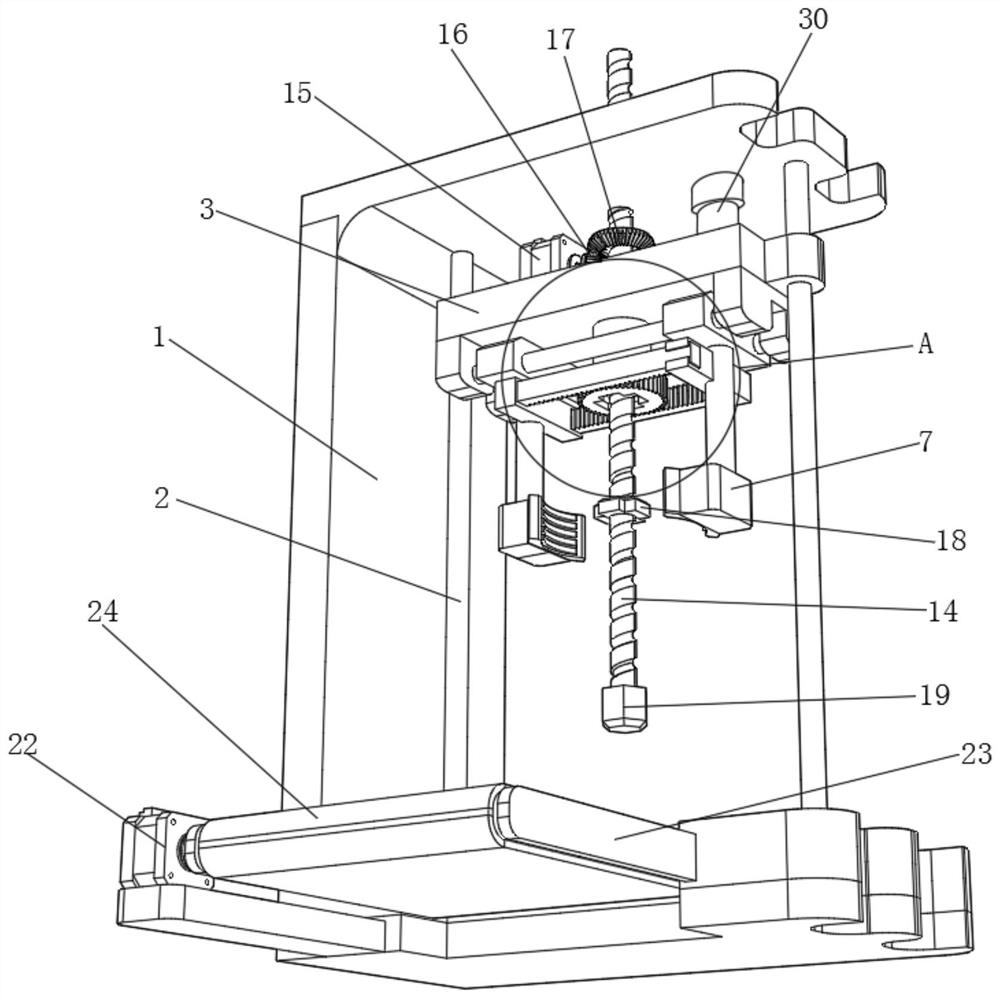

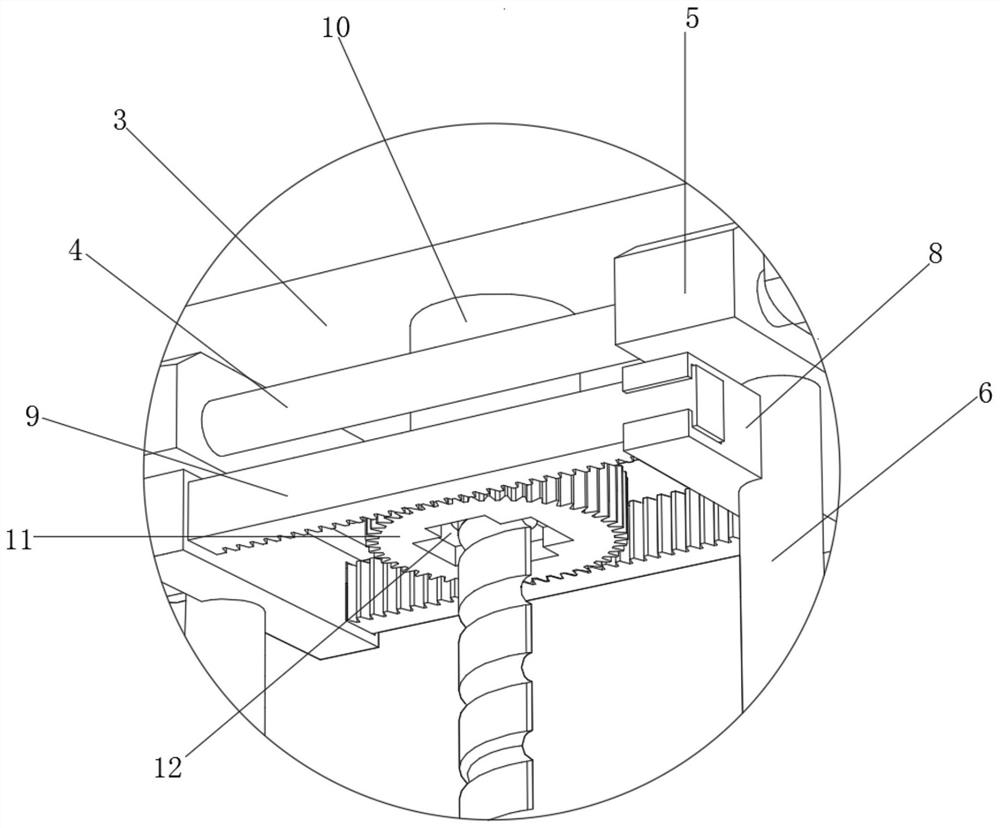

[0029] refer to Figure 1-Figure 4 , a new energy motor shell positioning gripper, including a support frame 1, two guide rods 2 are fixed by bolts in the support frame 1, and the outer walls of the guide rods 2 are slidably connected to the same installation block 3, and the installation block 3 Two sliding shafts 4 are fixed on the bottom by bolts, and two sliders 5 are slidably connected to one side of the outer wall of the sliding shafts 4, and the bottom side of the sliders 5 is fixed to a connecting column 6 by bolts, and the bottom of the connecting columns 6 all pass through Bolts are fixed with clamping blocks 7, and one side of the connecting column 6 is fixed with two fixed blocks 8 by bolts, and one side of the fixed blocks 8 is fixed with a rack 9 by bolts, and one side of the mounting block 3 is rotatably connected with a rotating column 10. And one side of the bottom end of the rotating column 10 is fixed with a rotating gear 11 by a bolt, and the cooperative us...

Embodiment 2

[0033] refer to Figure 5 , a new energy motor housing positioning gripper, including a connecting block 28 fixed to the bottom end of the connecting column 6 by bolts, and a plugging slot 29 is opened on one side of the connecting block 28, and a plugging slot 29 is inserted into the plugging slot 29. Connecting block 27, the other side of plugging block 27 is fixed with arc splint 26 by bolt, and the setting of splicing block 27 on the arc splint 26 and the insertion groove 29 on the connection block 28 can facilitate the replacement of arcs of different sizes. Shaped splint 26, so as to be able to better accurately grasp motor housings of different sizes, so as to better improve the grasping efficiency.

[0034] The working principle of this embodiment: when in use, when it is necessary to grab motor housings of different sizes, pull out the plug-in block 27 on the arc splint 26 from the slot 29 on the connection block 28, thereby replacing the arc splint 26. Grab motor ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com