Curable composition for inkjet printing, cured product thereof, and electronic component having the cured product

A curable composition, inkjet printing technology, applied in the directions of printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve the problems of unusable, high viscosity, and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

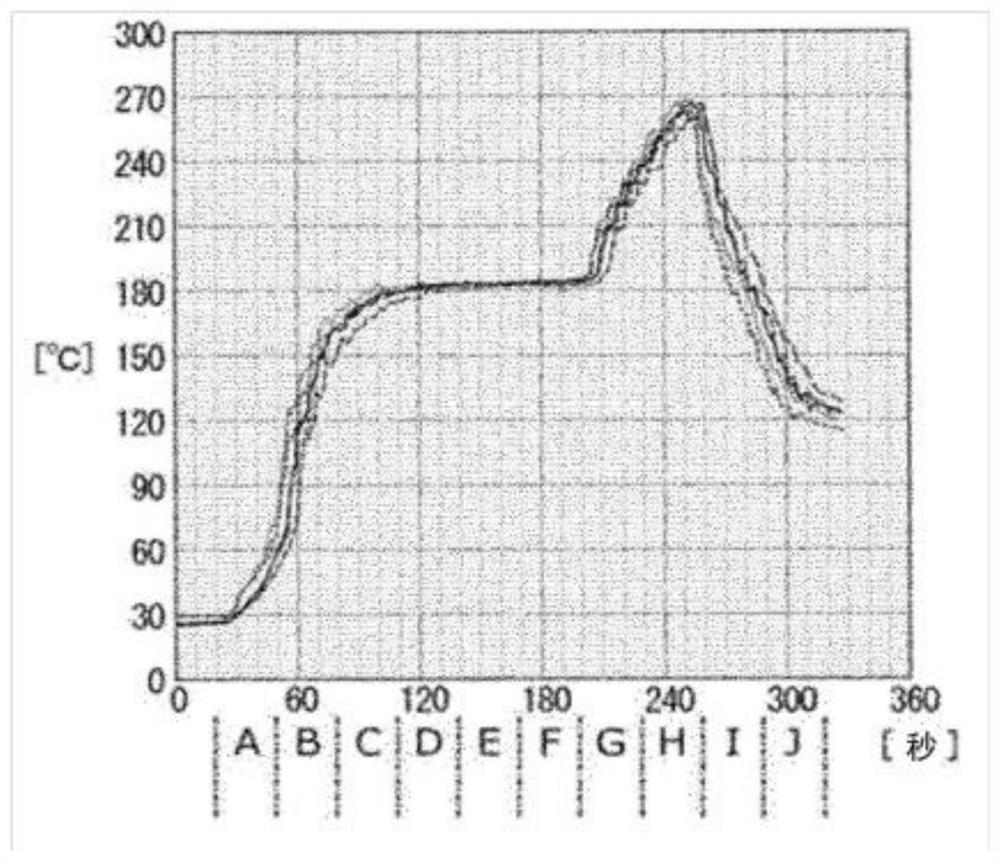

Image

Examples

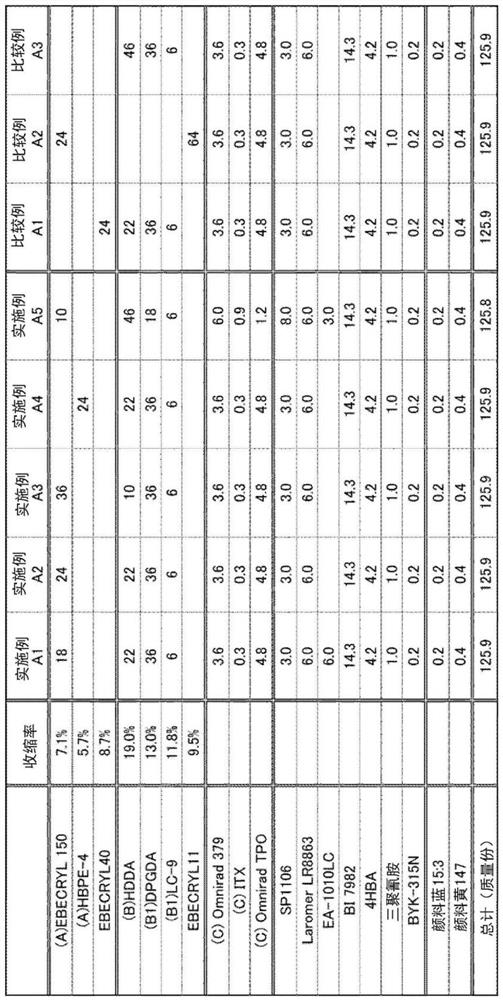

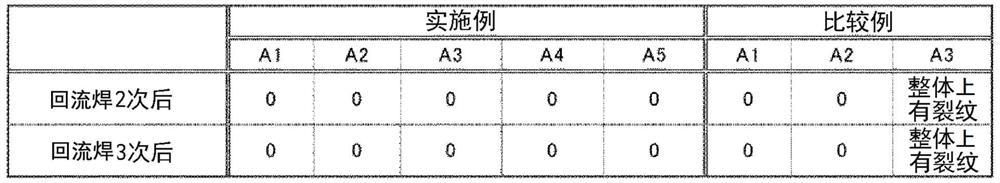

Embodiment A1~5 and comparative example A1~3

[0193] 1. Preparation of the composition

[0194] Each component was mixed by the ratio (unit: mass part) shown in Table 1, and it stirred with a dissolver. Then, dispersion was performed with 1 mm zirconia beads for 2 hours using a bead mill to obtain compositions of the present invention (Examples A1 to 5) and compositions not belonging to the present invention (Comparative Examples A1 to 3).

[0195] [Table 1]

[0196]

[0197] The product names and abbreviations in Table 1 are as follows.

[0198] EBECRYL 150: EO-modified bisphenol A diacrylate, manufactured by Daicel Ornex Co., Ltd.

[0199] HBPE-4: EO-modified hydrogenated bisphenol A diacrylate (EO 4 mole adduct), manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.

[0200] EBECRYL40: Pentaerythritol alkoxytetraacrylate, manufactured by Daicel Ornex Co., Ltd.

[0201] HDDA: 1,6-Hexanediol diacrylate, manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.

[0202] DPGDA: Dipropylene glycol diacrylate, manufact...

Embodiment B

[0275] Next, Example B will be described.

Embodiment B1~8 and comparative example B1~2

[0277] 1. Preparation of the composition

[0278] Each component was mixed in the ratio (unit: mass part) shown in Table 6, and it stirred with a dissolver.

[0279] Then, dispersion was performed with 1 mm zirconia beads by a bead mill for 2 hours to obtain compositions of the present invention (Examples B1 to 8) and comparative compositions (Comparative Examples B1 and B2).

[0280] [Table 6]

[0281]

[0282] The product names and abbreviations in Table 6 are as follows.

[0283] ABE-300: EO-modified bisphenol A diacrylate (EO 3 mole adduct), manufactured by Shin-Nakamura Chemical Industry Co., Ltd.

[0284] BPE-4: EO-modified bisphenol A diacrylate (EO 4 mole adduct), manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.

[0285] HBPE-4: EO-modified hydrogenated bisphenol A diacrylate (EO 4 mole adduct), manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.

[0286] BPE-10: EO-modified bisphenol A diacrylate (EO 10 mol adduct), manufactured by Daiichi Kogyo Pharma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com