Shock-absorption and high-strength concave-convex reinforcement pipe for bicycle or scooter

A high-strength, bicycle technology, used in bicycle frames, bicycle accessories, transportation and packaging, etc., can solve the problems of insufficient solder, unstable strength, large force, etc., and achieve the effect of compact internal structure, easy setting and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

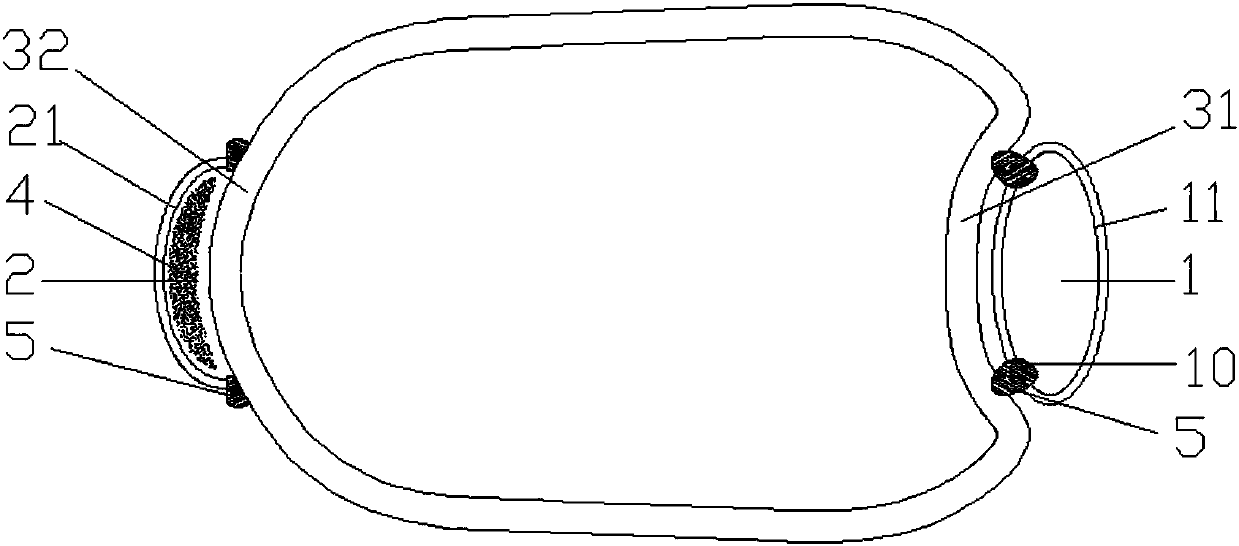

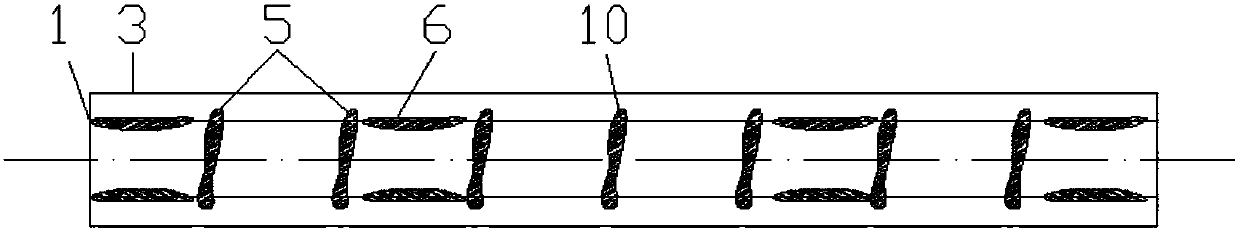

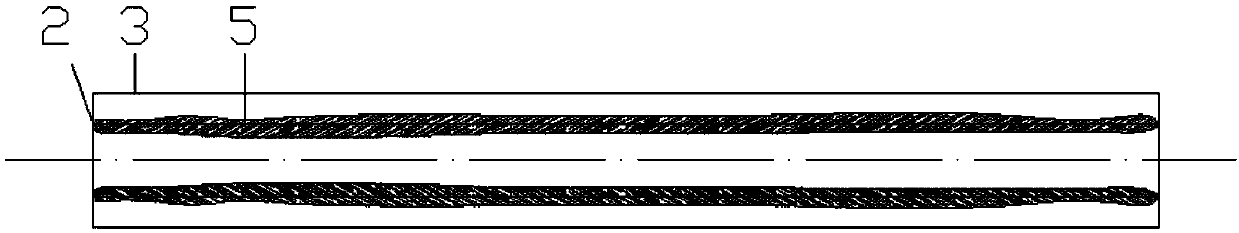

[0018] Such as Figure 1~2 , a shock-absorbing high-strength bicycle or scooter concave-convex reinforcing tube, used for welding the frame tube 3 for reinforcement, including a concave reinforcing tube 1 and a convex reinforcing tube 2, the concave reinforcing tube 1, The material of the convex reinforcement pipe 2 is 6061 aluminum profile, the thickness of the pipe wall of the concave reinforcement pipe 1 is 2.5-6mm, and the thickness of the pipe wall of the convex reinforcement pipe 2 is 4-7.5mm. In the reinforcement of the frame tube 3, the tube wall thickness of the convex reinforcing tube 2 is greater than the tube wall thickness of the concave reinforcing tube 1, and the concave reinforcing tube 1 includes a tube body 11, and the curvature of the tube body 11 is in line with that of the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com