Preprocessing method and manufacture method for Abelia macrotera (Graebn. et Buchw.) Rehd. bean jelly

A pretreatment and fairy technology, which is applied to the pretreatment method of fairy leaf jelly and the field of production thereof, can solve the problems of low success rate of production of fairy leaf jelly, irregular drying treatment of fresh leaves, and reduced quality, etc., and achieves color protection. Strong ability, food safety guarantee, and the effect of Q bomb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

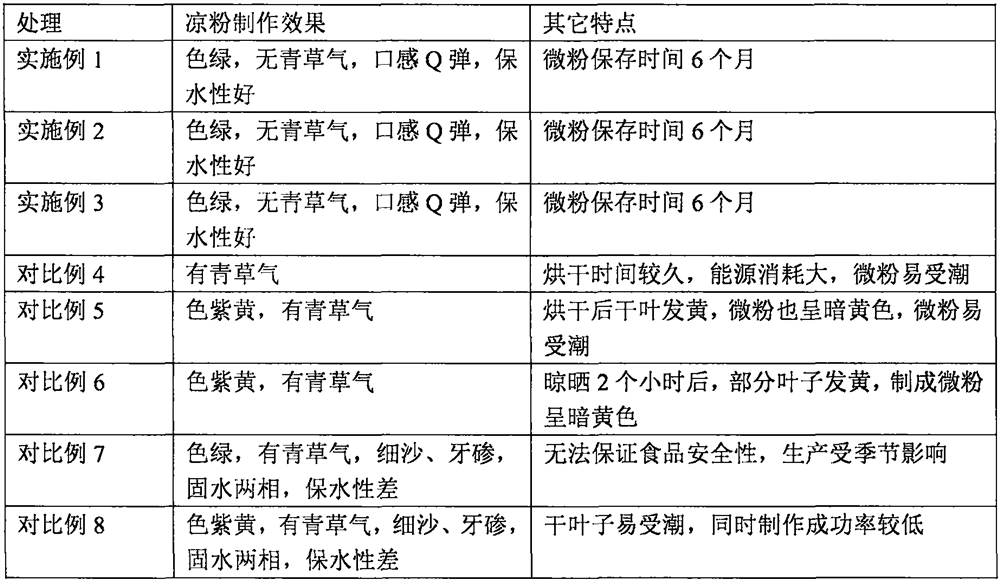

Examples

Embodiment 1

[0026] (1) Pretreatment of Immortal Leaf

[0027] a. Collect fairy leaves on a sunny day. The above-mentioned fairy leaves are fresh, and there are no yellow spots, black spots, etc. on the surface of the leaves.

[0028] b Rinse the collected leaves with running water, spread them flat in a clean place to dry for 1 hour.

[0029] c drying treatment: the temperature of the oven is raised to 120°C in advance, and the above-mentioned treated leaves are laid flat on the oven tray, and the tray is placed in the oven to dry at 115°C for 25 minutes, and then the temperature is lowered to 65°C until drying.

[0030] d pulverization: pulverize the dried fairy leaves with a superfine powder pulverizer, and sieve through a 200-mesh sieve after pulverization.

[0031] (2) Making of fairy leaf jelly

[0032] a Fully dissolve the superfine powder of fairy leaves in pure water at 100°C, the ratio of solid to liquid is 1:20, and keep stirring until the fairy leaves are fully dissolved.

...

Embodiment 2

[0036] a. Collect fairy leaves on a sunny day. The above-mentioned fairy leaves are fresh, and there are no yellow spots, black spots, etc. on the surface of the leaves.

[0037] b Rinse the collected leaves with running water, spread them flat in a clean place to dry for 1 hour.

[0038] c drying treatment: the temperature of the oven is raised to 135°C in advance, and the above-mentioned treated leaves are spread on the oven tray, and the tray is placed in the oven to dry at 130°C for 10 minutes, and then the temperature is lowered to 65°C until drying.

[0039] d pulverization: pulverize the dried fairy leaves with a superfine powder pulverizer, and sieve through a 400-mesh sieve after pulverization.

[0040] (2) Making of fairy leaf jelly

[0041] a Fully dissolve the superfine powder of fairy leaves in pure water at 100°C, the ratio of solid to liquid is 1:20, and keep stirring until the fairy leaves are fully dissolved.

[0042] b When the fairy leaves are fully dissol...

Embodiment 3

[0045] 1) pretreatment of fairy leaves

[0046] a. Collect fairy leaves on a sunny day. The above-mentioned fairy leaves are fresh, and there are no yellow spots, black spots, etc. on the surface of the leaves.

[0047] b Rinse the collected leaves with running water, spread them flat in a clean place to dry for 1 hour.

[0048] c drying treatment: the temperature of the oven is raised to 125°C in advance, and the above-mentioned treated leaves are laid flat on the oven tray, and the tray is placed in the oven to dry at 120°C for 15 minutes, and then the temperature is lowered to 65°C until drying.

[0049] d pulverization: pulverize the dry fairy leaves with a superfine powder pulverizer, and sieve through a 300-mesh sieve after pulverization.

[0050] (2) Making of fairy leaf jelly

[0051] a Fully dissolve the superfine powder of fairy leaves in pure water at 100°C, the ratio of solid to liquid is 1:20, and keep stirring until the fairy leaves are fully dissolved.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com