Enzymatic color-protecting laundry detergent

A laundry detergent and color-protecting technology, which is applied in the field of daily chemical products, can solve the problems of limited color-protecting effect and compatibility problems of non-ionic color-retaining agents, and achieve the effects of protecting color, satisfying washing performance, and reducing fabric color loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] An enzyme-added color-protecting laundry detergent is formed by mixing the following raw materials in mass percentages:

[0013] Saponin extract 25%; Tea saponin 2%; Carboxylic acid surfactant 3%; Fatty alcohol polyoxyethylene ether multi-surfactant 10%; Poly 4-vinylpyridine nitrogen oxide 1%; Liquid protease 0.5%; sodium citrate 1%; stilbene biphenyl fluorescent whitening agent 0.3%; sodium chloride 1%; isothiazolinone 0.1%; water 56.2%.

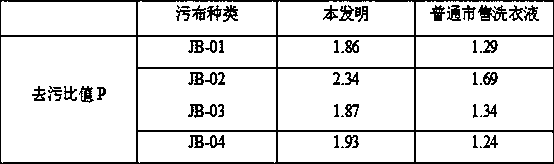

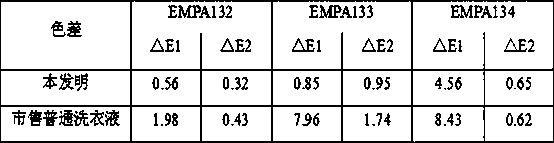

[0014] I. Decontamination performance test:

[0015] The decontamination performance test was carried out with reference to GB / T13174-2008 "Determination of Detergency and Cycle Washing Performance of Detergents for Clothing", prepared 250 ppm of washing water, and used milk stains JB-01, oil stains JB-02, and blood stains JB-03 , Perspiration JB-04 was tested, and the test results are shown in Table 1.

[0016] The decontamination performance test data of the enzyme color-protecting laundry detergent of the present invention and c...

Embodiment 2

[0026] An enzyme-added color-protecting laundry detergent is formed by mixing the following raw materials in mass percentages:

[0027] Saponin extract 40%; Tea saponin 1%; Carboxylic acid surfactant 5%; Fatty alcohol polyoxyethylene ether multi-surfactant 2%; Poly 4-vinylpyridine nitrogen oxide 0.1%; Liquid protease 0.3%; sodium citrate 5%; polyacrylic acid polymer 1%; Cathone 0.5%; water 45.4%.

Embodiment 3

[0029] An enzyme-added color-protecting laundry detergent is formed by mixing the following raw materials in mass percentages:

[0030] Saponin extract 30%; tea saponin 2%; carboxylic acid surfactant 10%; fatty alcohol polyoxyethylene ether multi-surfactant 2%; poly 4-vinylpyridine nitrogen oxide 0.5%; Liquid protease 0.6%; sodium citrate 3%; stilbene biphenyl fluorescent whitening agent 0.1%; sodium sulfate 0.1%; phenoxyethanol 0.3%; water 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com