Tooth covering top stopper, metal zipper with special function and using method of zipper

A technology of metal zippers with special functions, applied in the field of zippers, which can solve the problems that zippers cannot be reused, affect the service life of zippers, and cannot realize quick disengagement, etc., and achieve the effect of smooth and beautiful chain teeth, ensuring meshing strength and tight meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

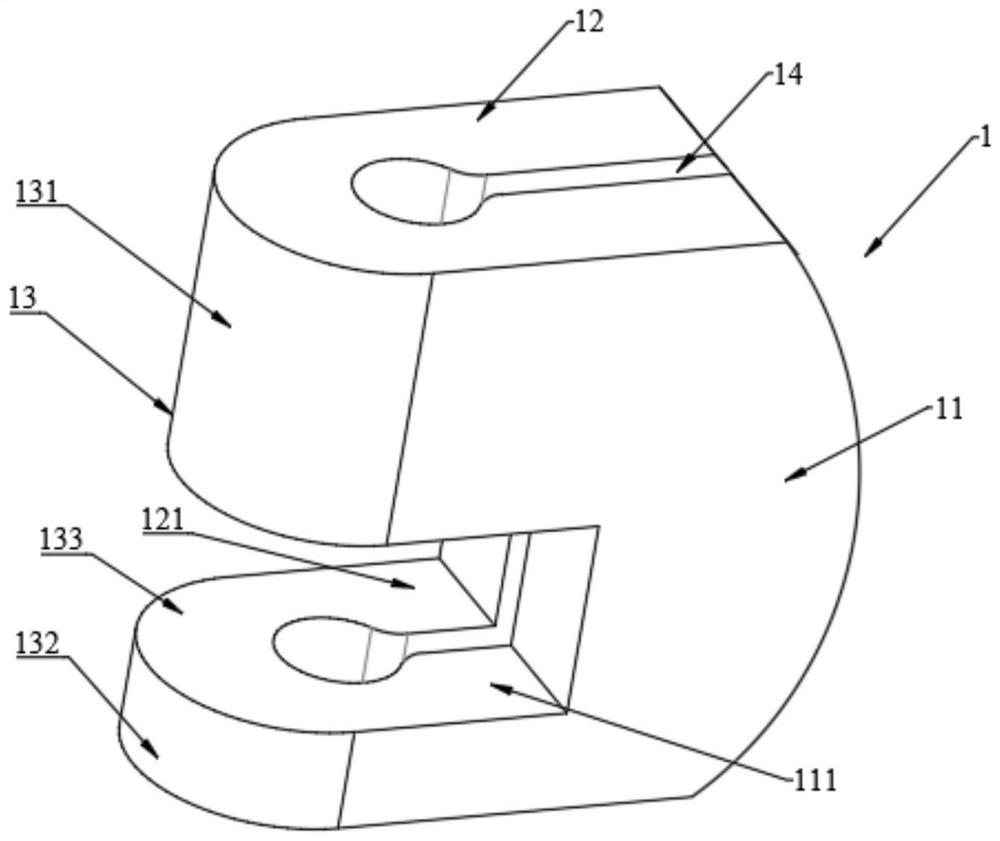

[0046] refer to figure 1 , a kind of tooth-wrapped top stop, installed at the end of the cloth tape that forms the zipper, is characterized in that it includes a front clamping copper sheet 11, a rear clamping copper sheet 12, and a transitional copper sheet 13, and the front clamping copper sheet 11 and the rear clamping copper sheet 12 are connected by a transition copper sheet 13 to form a U-shaped semi-opening structure, and the openings formed by the front clamping copper sheet 11, the transition copper sheet 13, and the rear clamping copper sheet 12 are used for Clamped on the cloth tape; the front clamping copper sheet 11, the rear clamping copper sheet 12, and the transitional copper sheet 13 are integrally formed;

[0047] The middle part of the front clamping copper sheet 11 is provided with several front transverse notches 111, and the front transverse notches 111 extend from the middle of the front clamping copper sheet 11 to one side end;

[0048] The middle part...

Embodiment 2

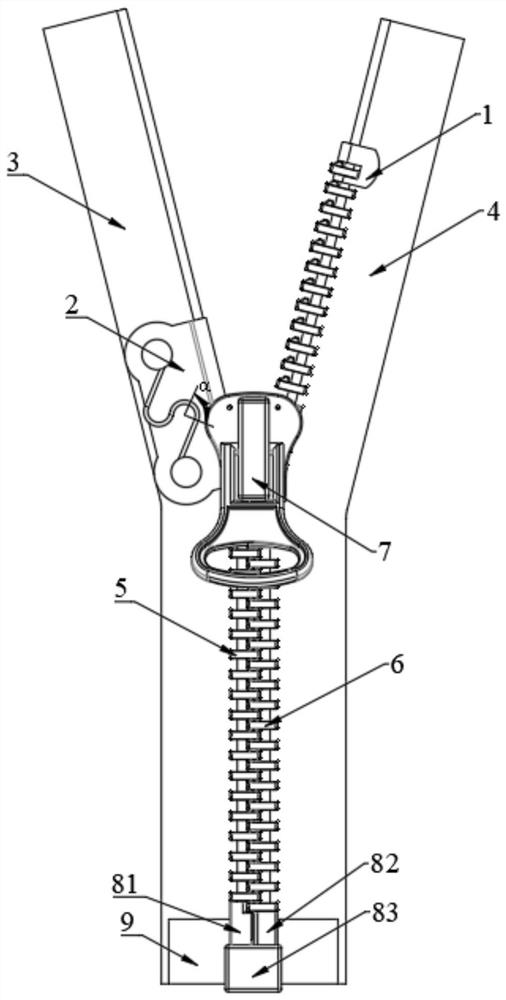

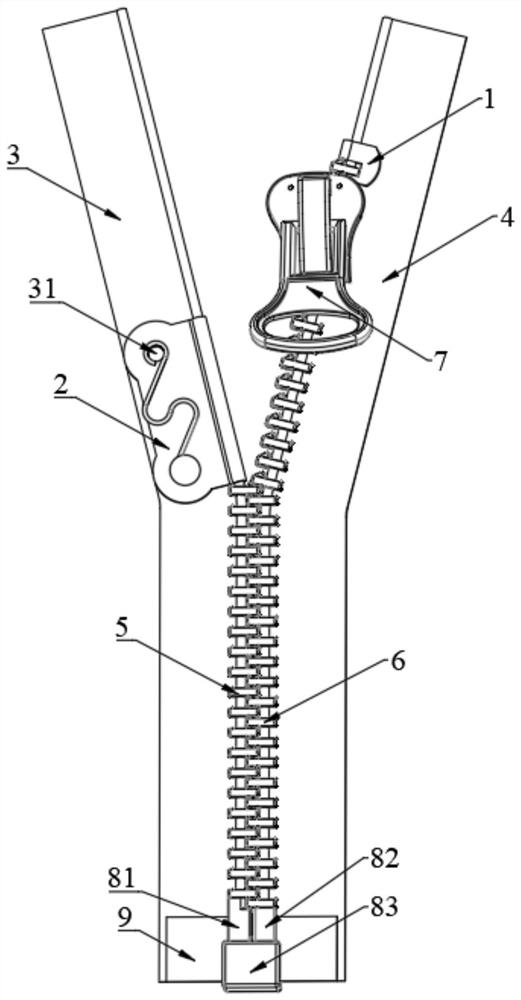

[0052] refer to figure 2 , image 3 , a metal zipper with special functions includes a left cloth tape 3, a right cloth tape 4, a left chain element 5 arranged on the left cloth tape 3, a right chain tooth 6 arranged on the right cloth tape 4, and a slider 7, the A left intubation tube 81 is arranged below the left chain tooth 5 at the bottom of the left cloth belt 3, and a right intubation tube 82 and a socket 83 are arranged at the bottom of the right chain tooth 6 at the bottom of the right cloth belt 4. 82 is integrally formed with the socket 83; it also includes a left upper stop assembly 2 and a right upper stop 1, and the right upper stop 1 is a tooth-wrapped upper stop as described in Embodiment 1; the lower ends of the left cloth belt 3 and the right cloth belt 4 A reinforcing tape 9 is provided, and the reinforcing tape 9 is provided with the left cloth tape 3 and the right cloth tape 4 for fixing the left intubation tube 81 , the right intubation pipe 82 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com