Municipal lake floating garbage salvage ship

A technology for salvaging boats and lakes, which is applied to special-purpose ships, general water supply conservation, and open water surface cleaning. Salvage, restore the effect of normal falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

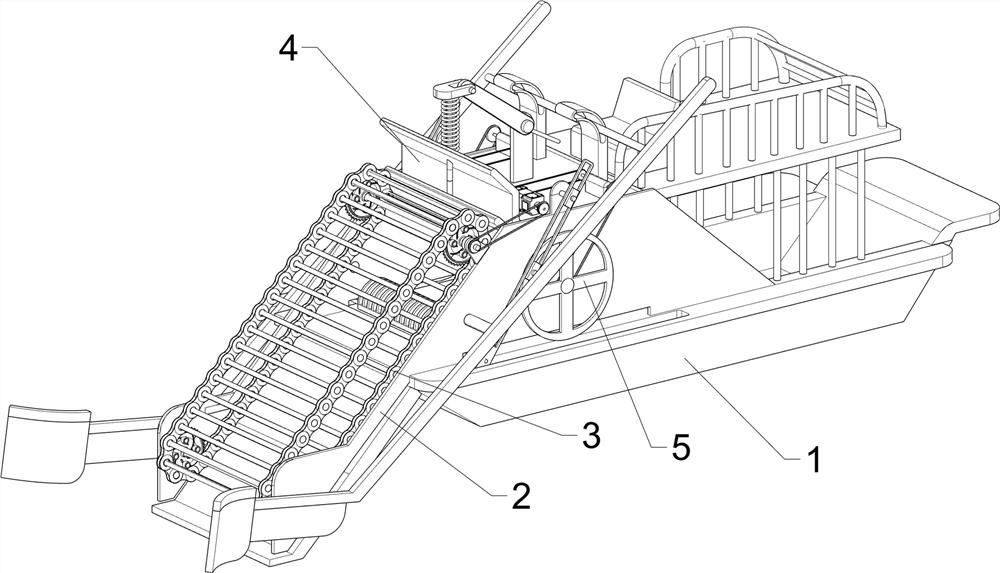

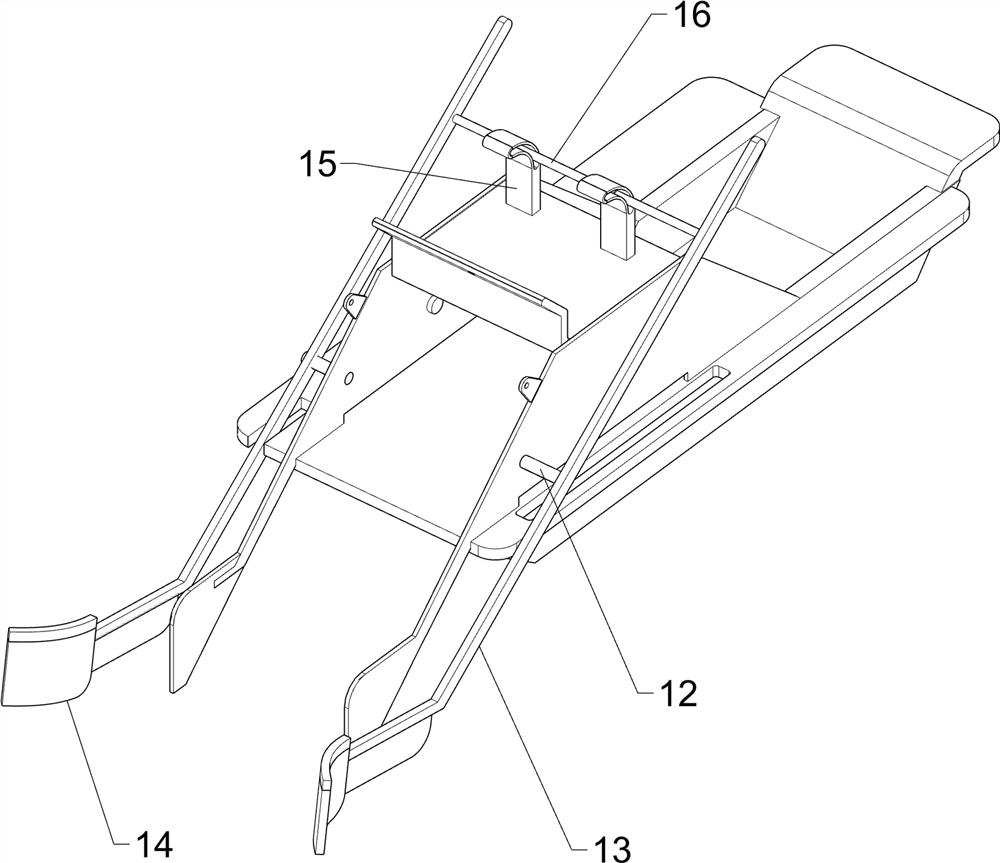

[0023] A municipal lake floating garbage salvage ship, such as Figure 1-3 As shown, it includes a hull 1, a support frame 2, a transmission mechanism 3, a baffle plate 4 and a pushing mechanism 5, the left side of the hull 1 is provided with a support frame 2, the upper part of the support frame 2 is fixedly connected with a baffle plate 4, and the left side of the support frame 2 A transmission mechanism 3 is provided, and a push mechanism 5 is provided on the support frame 2 .

[0024] When people need to use this device, first move this device into the water, then people can sit on the support frame 2 to operate, so that this device moves in the water, and then people start the transmission mechanism 3 to salvage the floating garbage on the lake In the hull 1, the baffle plate 4 can block the garbage so that it will not fall on the top of the support frame 2, and at the same time, the transmission mechanism 3 drives the driving mechanism 5 to move, so that the pushing mech...

Embodiment 2

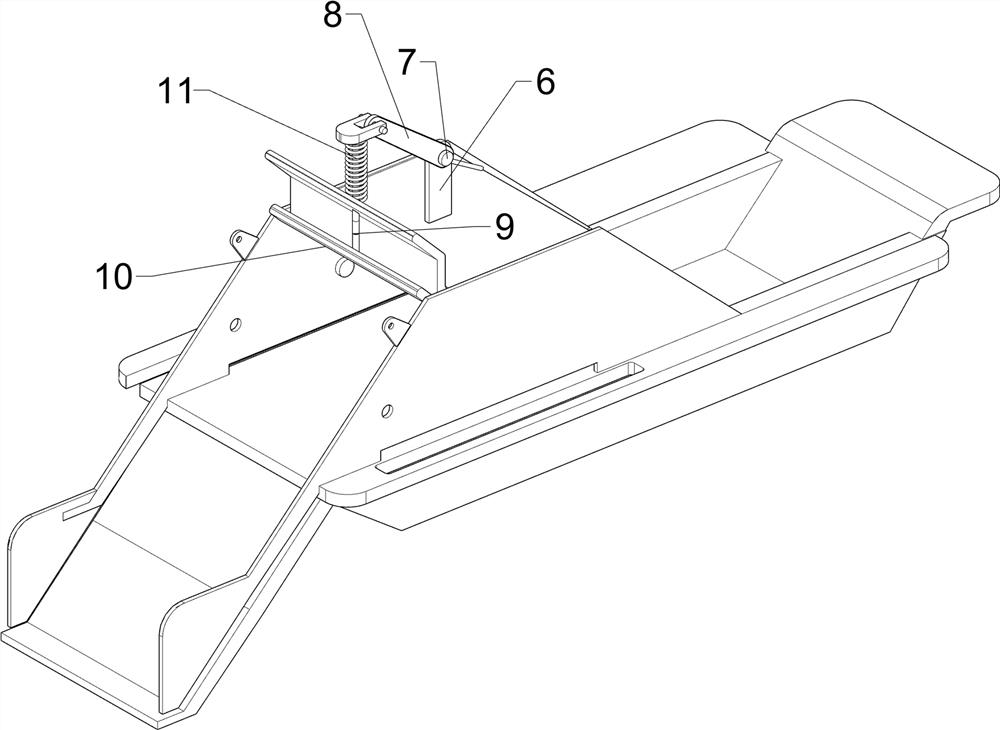

[0030] On the basis of Example 1, such as Figure 4-5 As shown, it also includes a support plate 6, a third rotating shaft 7, a connecting plate 8, a pull rod 9, an extruded block 10, and an elastic member 11. A support plate 6 is arranged in the middle of the top of the support frame 2, and the support plate 6 is rotated. A third rotating shaft 7 is connected, and a connecting plate 8 is arranged on the third rotating shaft 7, and a tie rod 9 is fixedly connected to the connecting plate 8, and the pulling rod 9 is slidingly connected with the baffle plate 4, and the bottom end of the pulling rod 9 is provided with an extrusion block 10, and An elastic member 11 is connected between the plate 4 and the pull rod 9, and the elastic member 11 is a compression spring.

[0031] When there is more garbage and the gap between the transmission mechanism 3 and the support frame 2 is blocked, people can pull the right end of the connecting plate 8 upwards, so that the pull rod 9 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com