Frame structure and mobile crane

A frame structure and frame technology, which is applied to cranes and other directions, can solve the problems of not being able to fully utilize the box-shaped torque transmission capacity of the frame, and achieve the effects of improving disassembly and assembly efficiency, reducing use time, and reducing driving weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

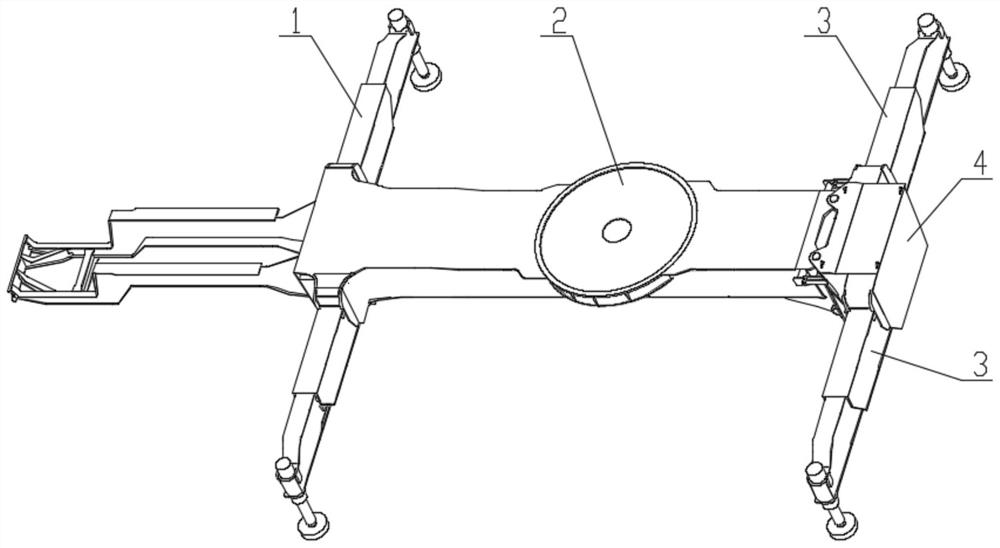

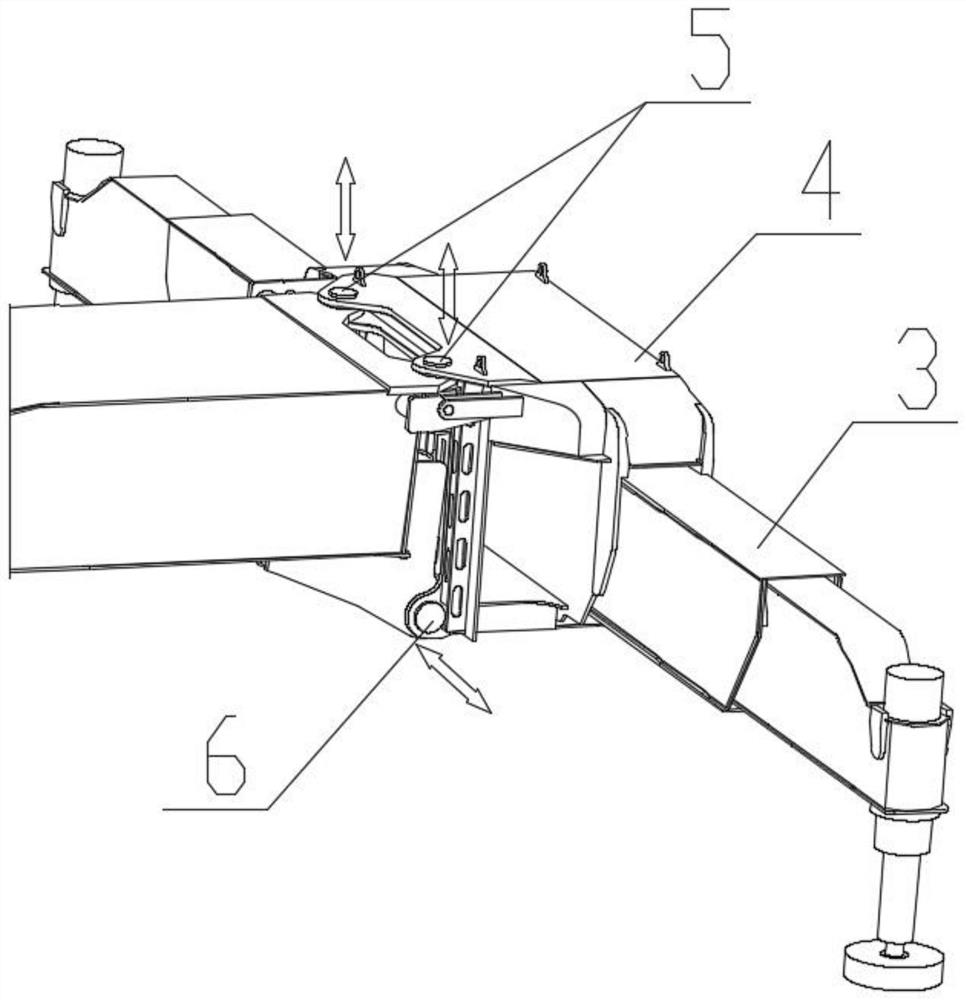

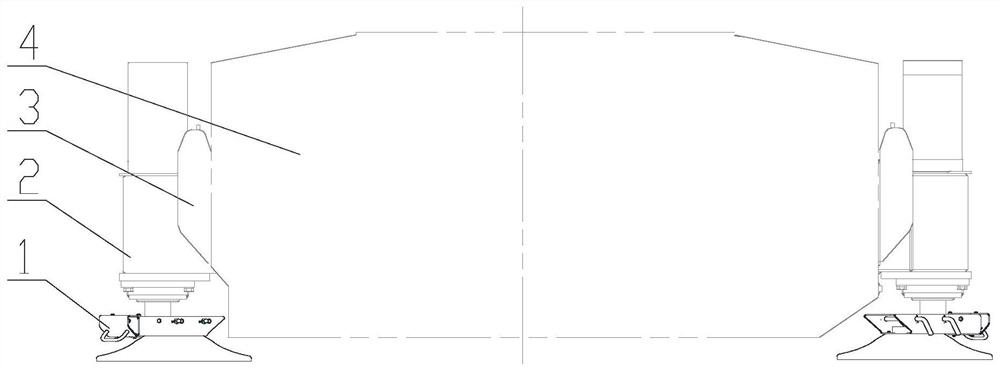

[0043]A vehicle frame structure, comprising a vehicle body 17 and a detachable part 4, the detachable part 4 is located in the longitudinal direction of the vehicle body 17; , hydraulic valves, etc.; the detachable part is connected to the vehicle body through pin shafts, and the pin shafts include two groups, namely the upper pin shaft group 5 and the lower pin shaft group 6; Direction setting, the lower pin group 6 is set along the vertical direction of the vehicle, such as figure 2 shown.

[0044] Described vehicle body 17 comprises vehicle frame 2, and described vehicle frame 2 is positioned at the longitudinal length direction of vehicle body 17; It acts as a supporting force; the movable legs include a front movable leg 1 and a rear movable leg 3; the front movable leg 1 and the rear movable leg 3 are located on both sides of the vehicle frame 2; Under the action of the oil cylinder, it can move telescopically along the fixed box in the frame 2, and its retracted and ...

Embodiment 2

[0059] A mobile crane includes the vehicle frame structure described in Embodiment 1. The vehicle frame structure can be disassembled into at least two parts in the longitudinal direction of the vehicle. In particular, the disassembled part contains the movable outrigger box type. The patented technology also relates to the connection structure of the disassembled part.

[0060] Acronyms and key term definitions:

[0061] Frame: The structural component of the crane, which is the installation carrier of the power system, driving system and other assembly devices, and at the same time plays a supporting role in the operation of the crane.

[0062] Movable Outrigger: A box-shaped structure that can be retracted back and forth to support a crane.

[0063] Fixed outriggers: Belonging to a part of the frame, it is a hollow box-shaped structure, and the movable outriggers can be telescopically moved in the hollow box.

[0064] Vehicle body: the concept of the vehicle body struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com