Novel girder erection equipment and erection method

A new type of equipment and technology, applied in the direction of bridge construction, erection/assembly of bridges, bridges, etc., to achieve the effect of less investment, simple operation and fast erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

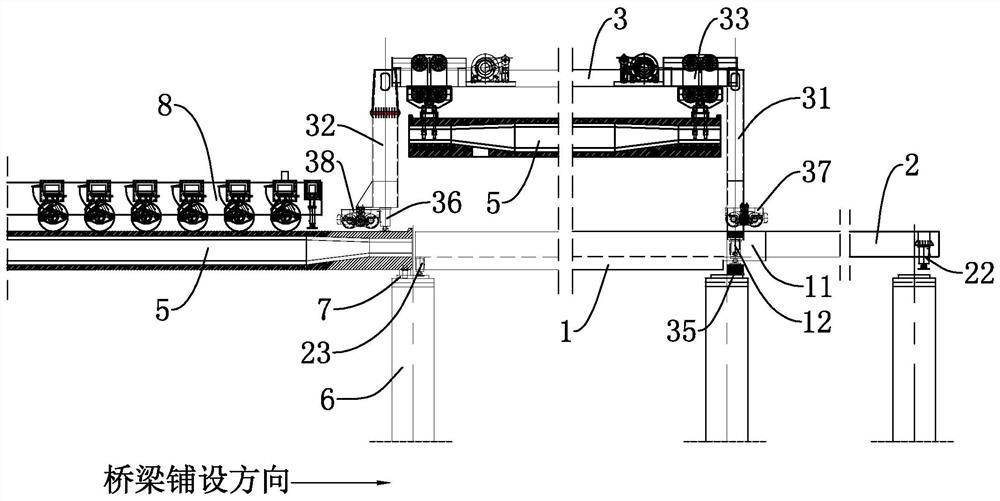

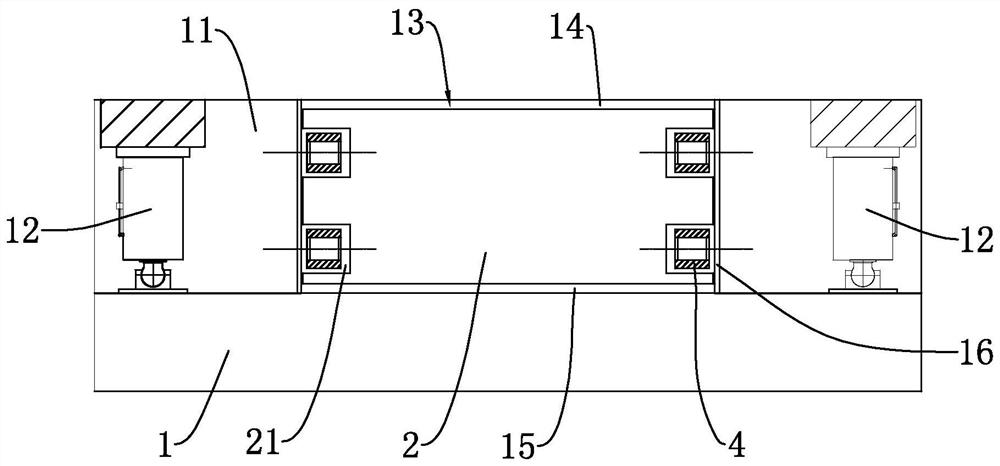

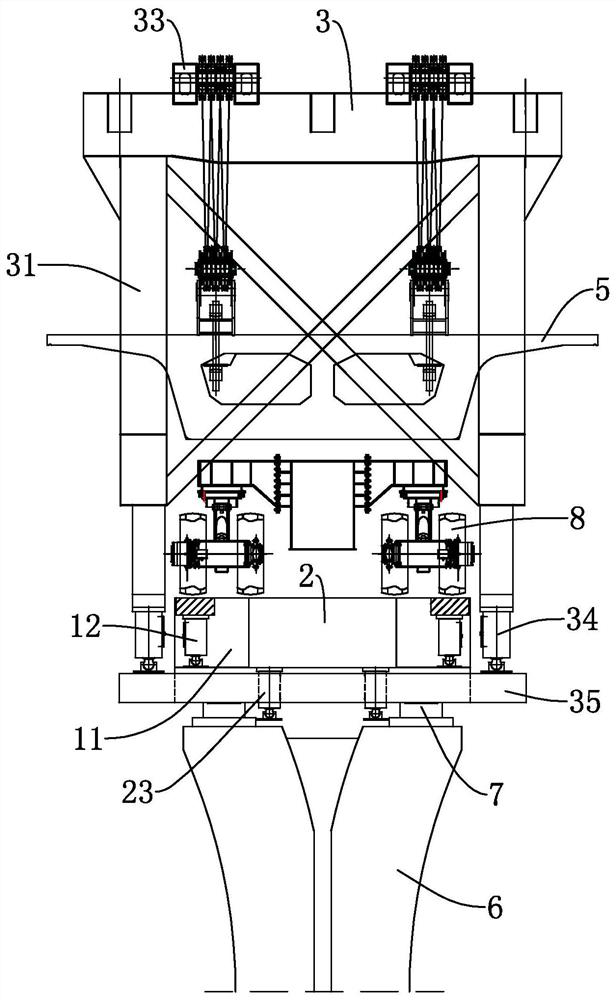

[0044] The embodiment of the present invention discloses a new type of beam erecting equipment, which is used to quickly and stably erect the beam 5 to be erected on the beam erecting hole position of the bridge pier 6 . The beam erection hole position is the position between two adjacent bridge piers 6 to be erected in the direction of bridge laying, and the bridge piers 6 to be erected are provided with supporting pad stones 7 to support the beam 5 to be erected.

[0045] refer to figure 1 , the new beam erection equipment includes a hole beam 1, an inner guide beam 2, and a falling beam door frame 3 that can walk on the hole beam 1 to lift or lower the beam 5 to be erected. The hole beam 1 is a special steel box girder, which consists of several Beam segments are spliced together.

[0046]The beam length of passing beam 1 needs to be equal to the lengt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap