Construction method of large-span profile steel reinforced concrete beam

A technology of concrete beams and construction methods, which is applied to the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of inaccurate positioning of steel keels, time-consuming and labor-intensive construction projects, and occupation of crane resources, etc., to achieve The effect of saving construction resources, improving construction efficiency, good positioning and support and fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

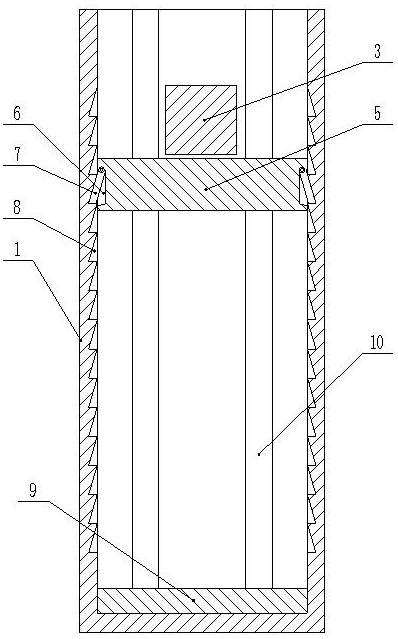

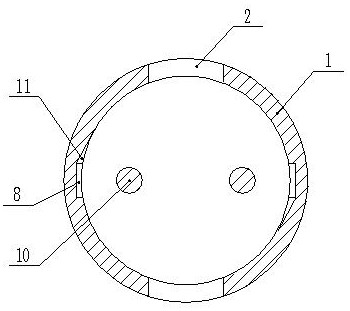

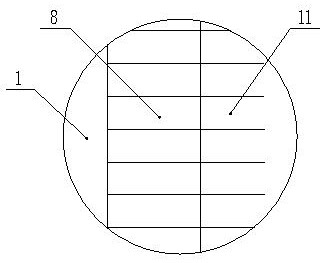

[0029] Embodiment 1: as Figure 1-4 , a construction method for a long-span steel concrete beam, comprising the steps of:

[0030] 1) Install multiple sets of scale lifting pipe devices on the bottom form of the steel concrete steel beam to be installed, and two scale lifting pipe devices are arranged opposite to each other to form a set of support units;

[0031] The lifting pipe device with a scale scale used in the construction includes a lifting pipe body 1, and two chute 2 are vertically opened on the side walls of the opposite sides of the lifting pipe body 1, and the chute 2 runs through the jacking pipe body 1. The upper end of the pipe body 1; a jacking beam 3 is horizontally provided in the chute 2, and the jacking beam 3 passes through the chute 2 and is connected to it by sliding fit;

[0032] 2) Use a crane to hoist the shaped steel beam to between the two graduated ruler lifting pipe devices, and clamp the graduated ruler lifting pipe device to the upper flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com