Fully mechanized coal mining face system for improving recovery ratio of mining area

A technology for fully mechanized mining face and working face, which is applied in ground mining, mining equipment, earth-moving drilling, etc. Recovery rate, prevent the outflow of harmful gas, and improve the effect of green and clean mining level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

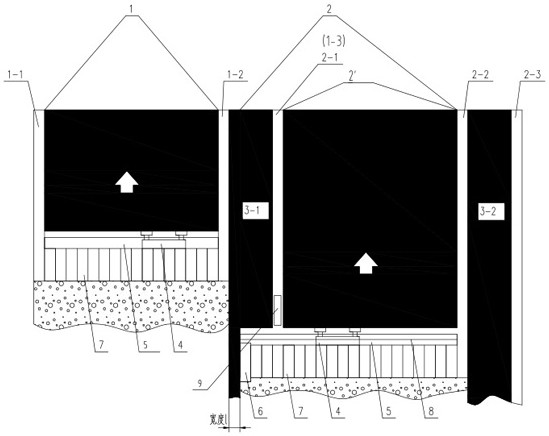

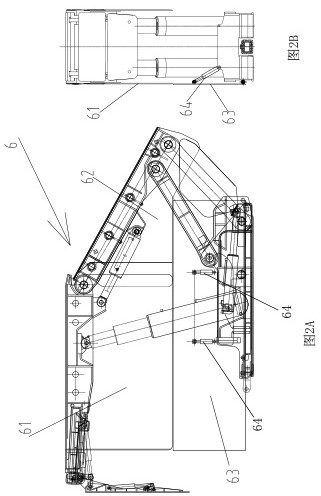

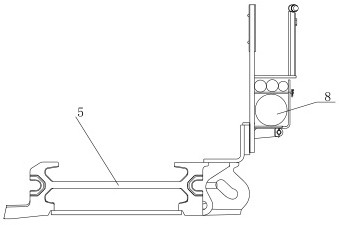

[0016] Such as Figure 1 to Figure 3 As shown, a fully mechanized mining face system for increasing the recovery rate of the mining area of the present invention includes coal pillars A (3-1) and air return lanes (2-1) of the first mining face arranged horizontally in sequence, and the recovery of solid coal , the belt transport lane (2-2), the coal pillar B (3-2) of the next working face and the auxiliary transport lane (2-3), a shearer (4) and a scraper conveyor are set behind the solid coal mining Machine (5), large side guard reinforced hydraulic support (6) and hydraulic support (7), the large side guard reinforced hydraulic support (6) is arranged at the coal pillar A (3-1) of the first mining face side, such as figure 2 As shown in A and 2B, the large side guard plate reinforced hydraulic support (6) includes a reinforced and lengthened top beam side guard plate (61), a reinforced and lengthened cover beam side guard plate (62), and a reinforced and extended base si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com