Real-time pressure detection supporting device for slag treatment roller

A technology of real-time pressure and support device, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problems of wear of supporting wheel shell, thrust wheel shell and supporting ring, axle impact fracture, unobservable development process, etc. Equipment installation, optimizing equipment design, and achieving predictive maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

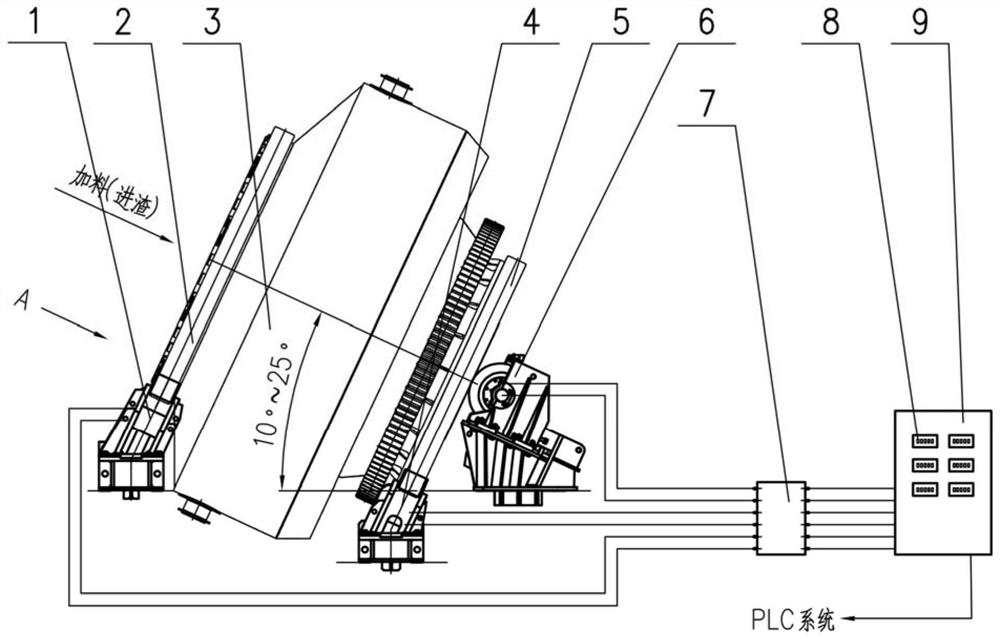

[0033] The following will combine Figure 1 to Figure 5 A detailed description of a real-time pressure detection support device for a slag treatment drum provided by the present invention is given. The scope of protection is not limited to the following embodiments, and those skilled in the art can modify and embellish it within the scope of not changing the spirit and content of the present invention.

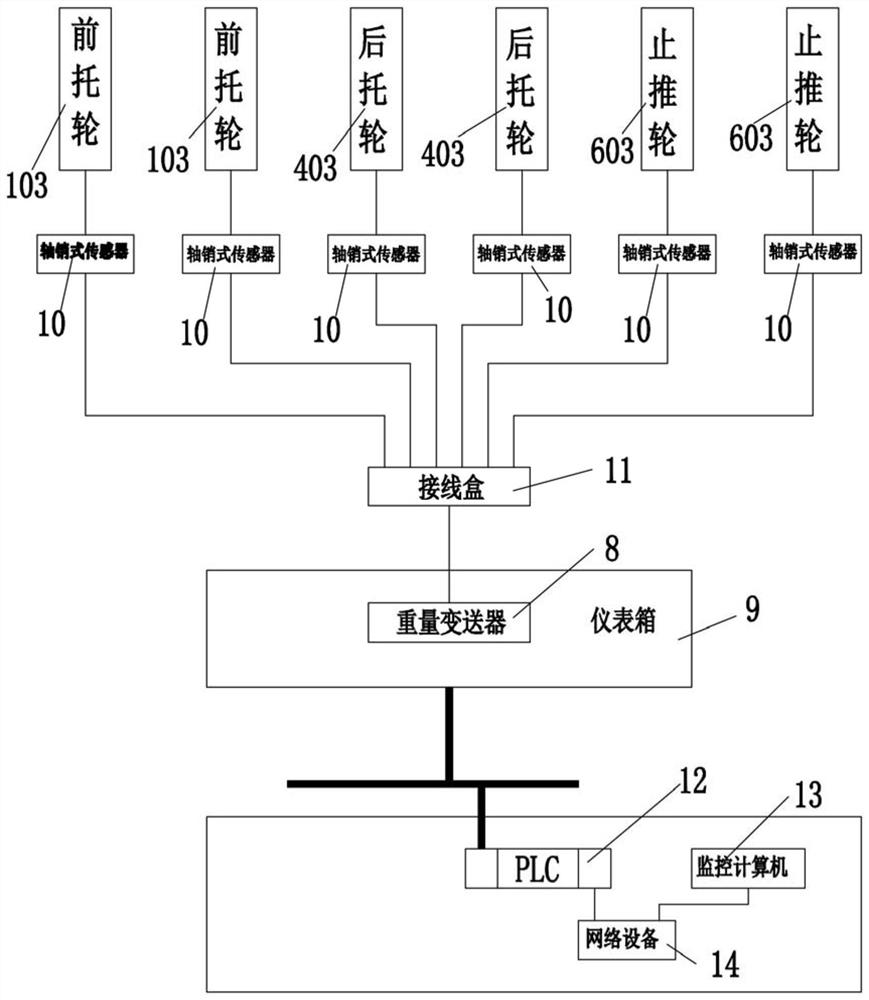

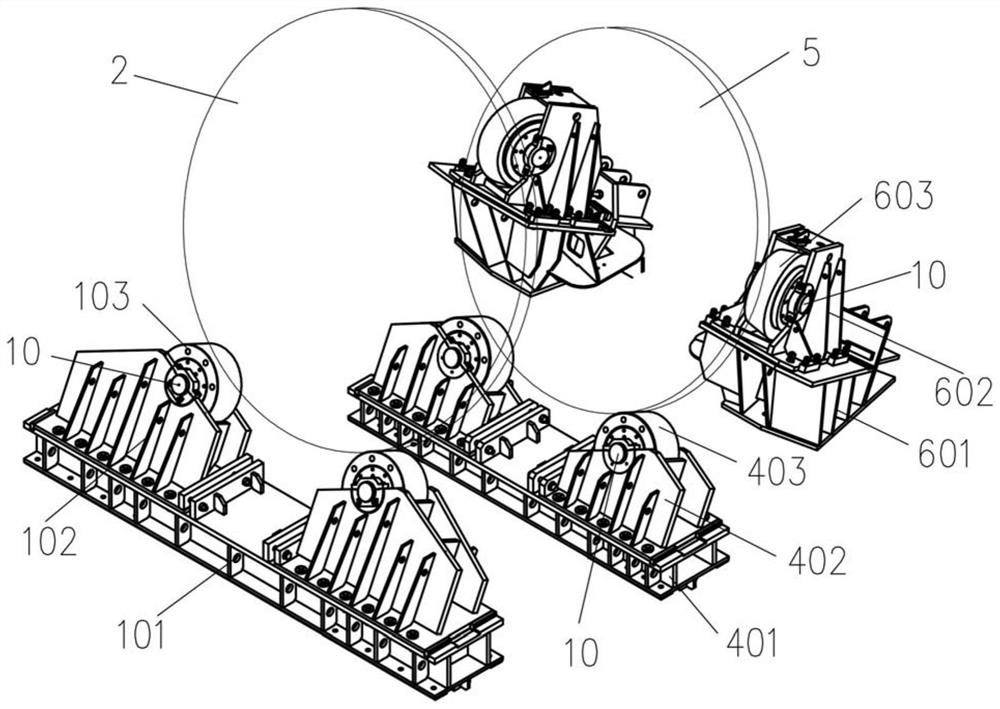

[0034] Please refer to Figure 1 to Figure 5 , a support device for real-time pressure detection of a slag processing drum, comprising a force-measuring front supporting wheel device 1, a force-measuring rear supporting wheel device 4, a force-measuring thrust wheel device 6 and a weight transmitter 8, the force-measuring front supporting wheel The axles of device 1, the force-measuring rear supporting wheel device 4 and the force-measuring thrust wheel device 6 all adopt pivot pin sensors 10, and the pin pin sensors 10 are electrically connected with the weight transmitter 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com