Fault diagnosis system and method for high-power permanent magnet motor

A fault diagnosis system and permanent magnet motor technology, applied in the direction of motor generator testing, etc., can solve the problems of inaccurate diagnosis, inability to detect motor loss of field faults, and high cost, so as to improve system reliability, achieve predictive maintenance, and effectively The effect of fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

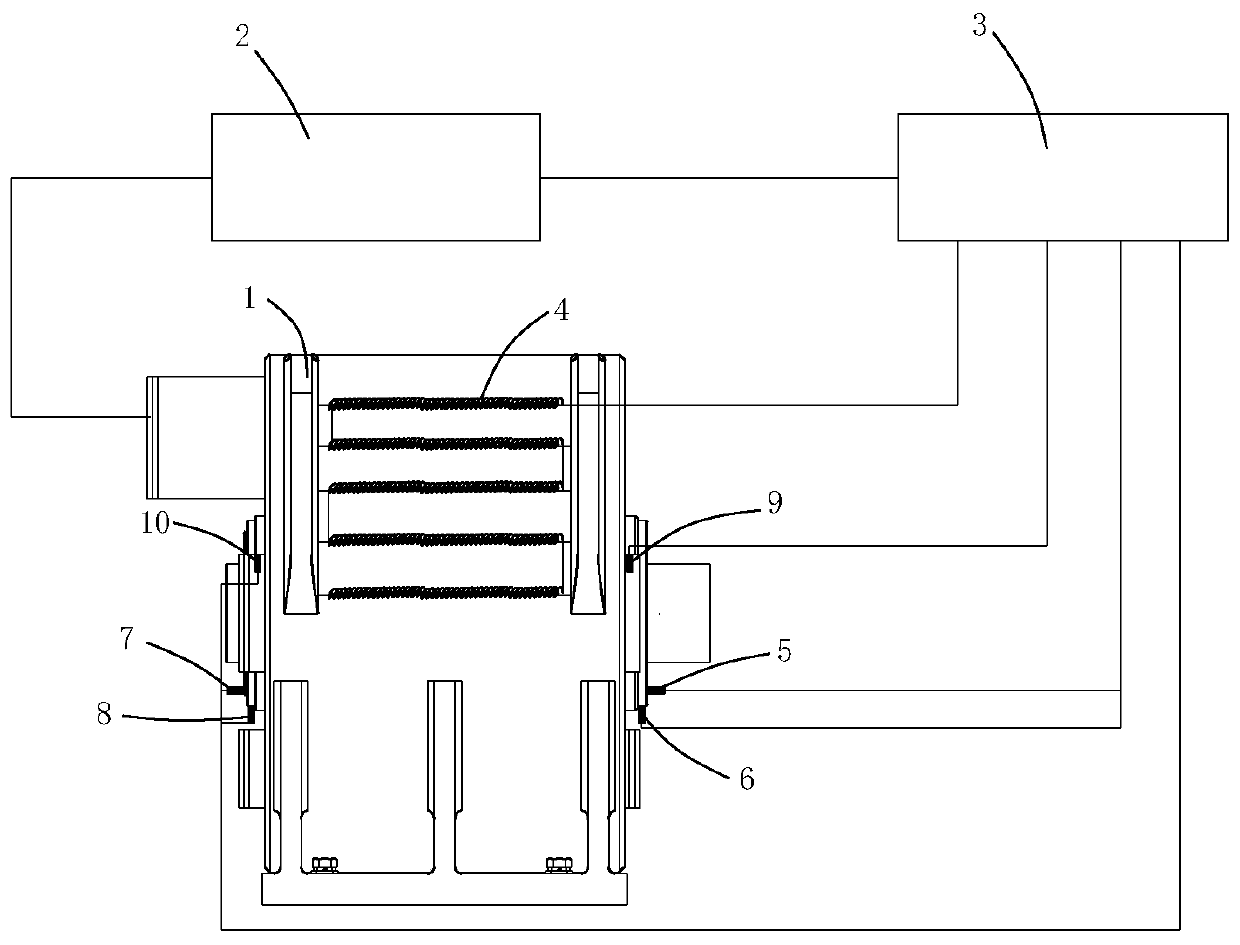

[0036] to combine figure 1 , a high-power permanent magnet motor fault diagnosis system, including a permanent magnet motor 1, a servo controller 2 and an industrial control computer 3.

[0037] The permanent magnet motor 1 is connected with the servo controller 2, and the servo controller 2 is electrically connected with the industrial control computer 3. The permanent magnet motor 1 is provided with a vibration sensor and a temperature sensor, and both the vibration sensor and the temperature sensor are connected with the industrial control computer. The magneto is also connected with the industrial control computer 3 through the temperature measuring optical fiber 4 .

[0038] The servo controller 2 collects the current signal of the permanent magnet motor 1, and uploads the current signal to the industrial control computer, and the industrial control computer 3 controls the permanent magnet motor 1 to stop through the servo controller.

[0039] The industrial control comp...

Embodiment 2

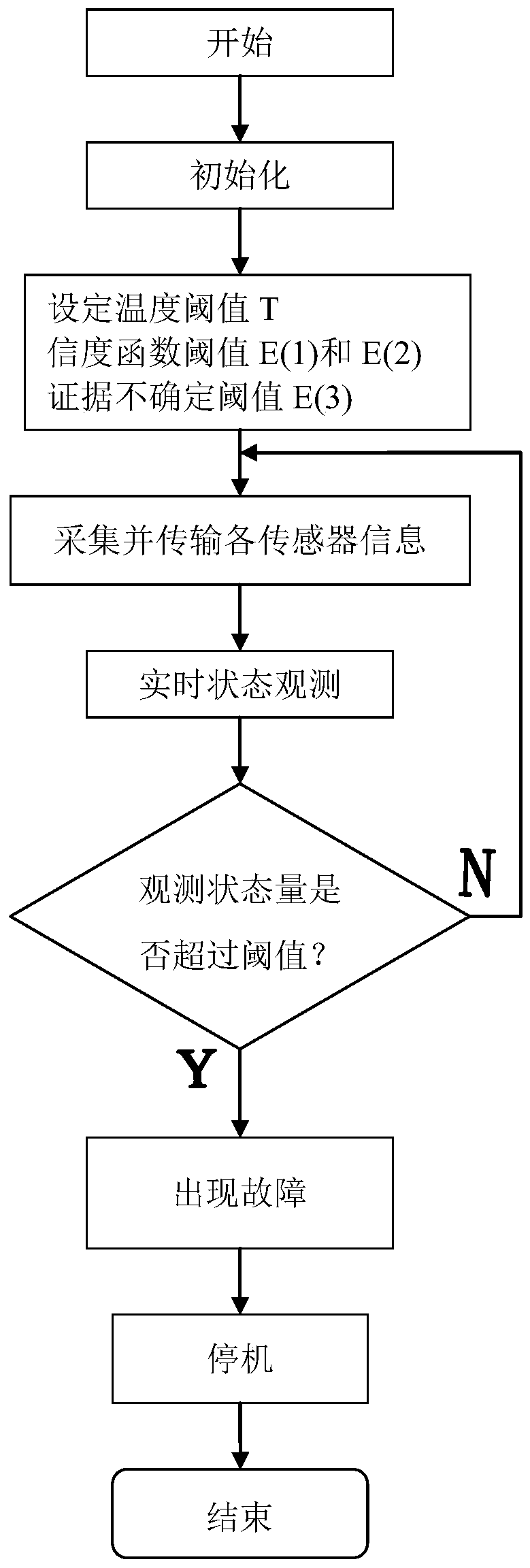

[0049] The diagnosis method of a kind of high-power permanent magnet motor fault diagnosis system described in the above-mentioned embodiment comprises the following steps:

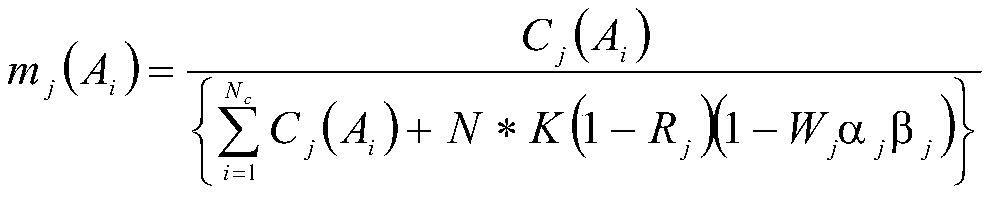

[0050] Step 1: According to the status and monitoring requirements of the actual high-power permanent magnet motor, a motor temperature rise model is established for motor over-temperature faults, and a multi-source sensor fusion fault diagnosis model based on D-S theory is established for motor bearing faults and motor demagnetization faults;

[0051] Motor temperature rise model: Since the temperature of different positions of the stator winding of the permanent magnet motor is different, in order to realize distributed comprehensive detection, the center of the permanent magnet motor shaft is used as the origin to establish a three-dimensional coordinate system of the motor, and the temperature of the stator winding of the motor is divided into grids. Perform coordinate simulation calculation output to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com