Soil sampling device for highway engineering

A soil sampling and engineering technology, applied in the direction of sampling devices, etc., can solve the problems of soil layer damage, difficult to take out, difficult to penetrate deep into the soil, etc., and achieve the effect of high efficiency and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

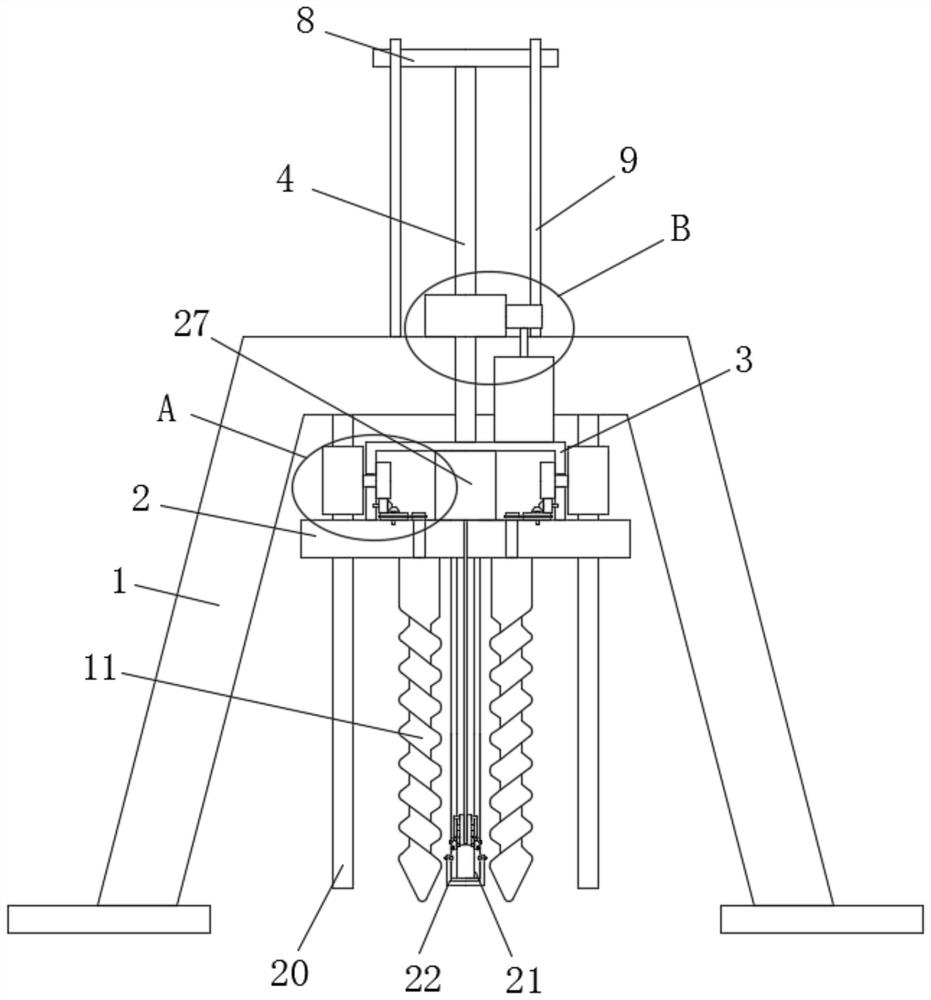

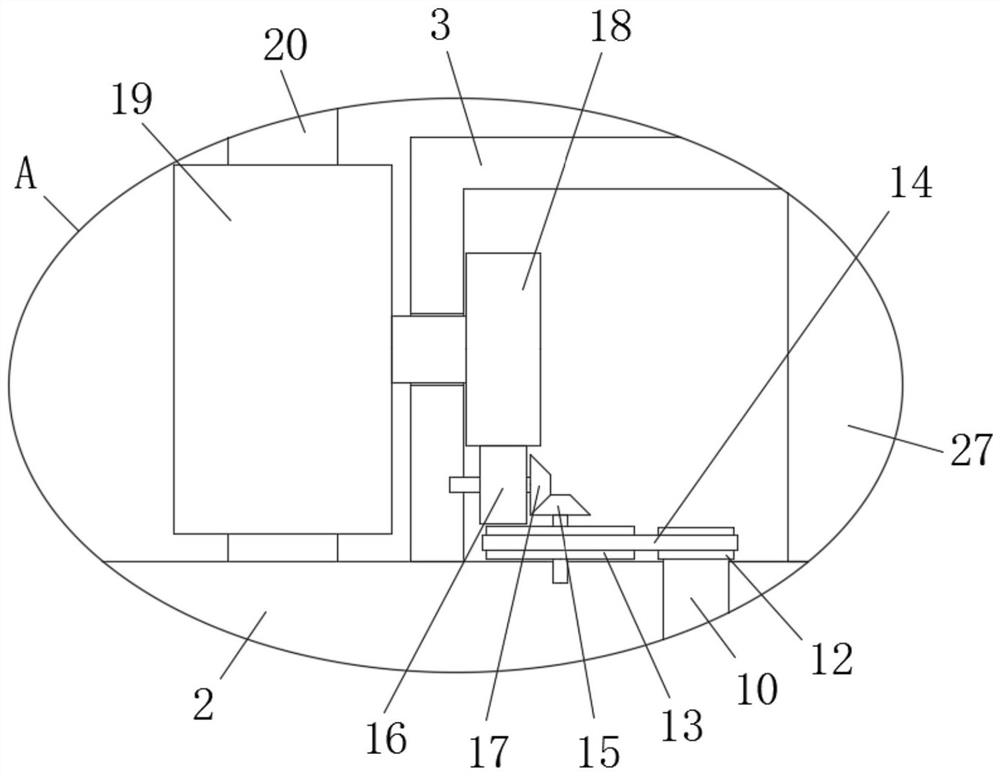

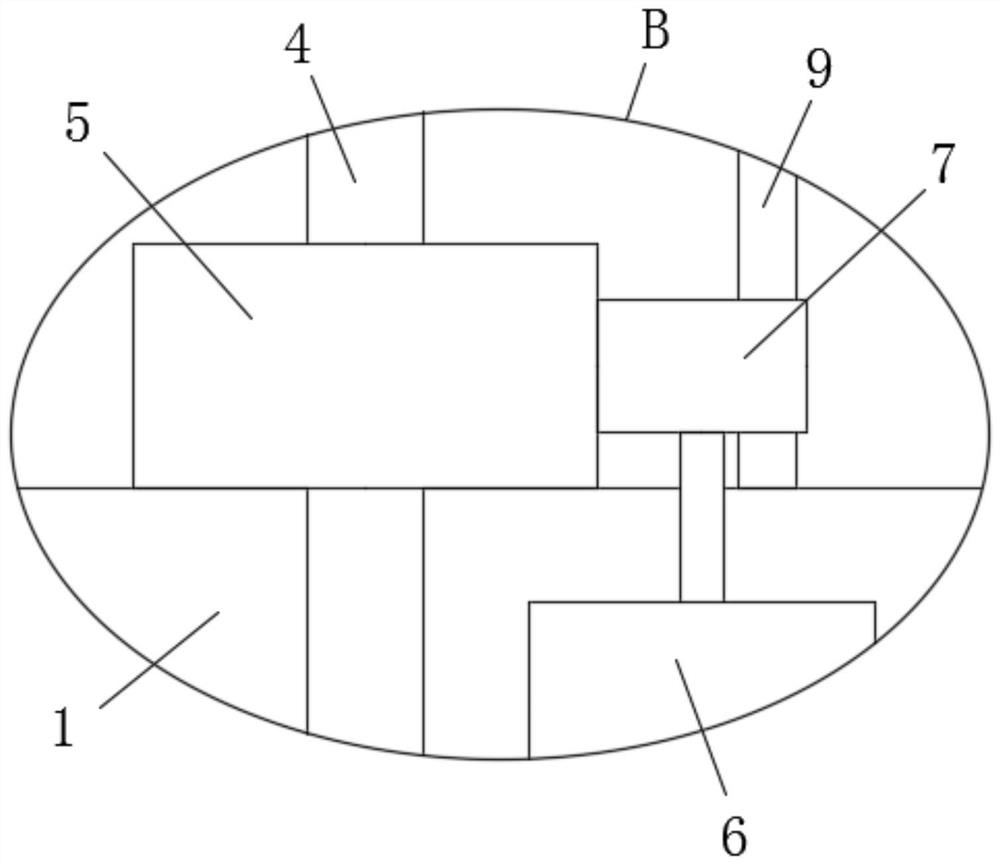

[0026] refer to Figure 1-7, a soil sampling device for highway engineering, comprising a sampling frame 1, the sampling frame 1 is provided with a moving plate 2, the top of the moving plate 2 is fixedly equipped with a control box 3, and the top of the control box 3 is fixedly connected with a first screw rod 4, The top of the sampling rack 1 is provided with a sliding hole, the first screw rod 4 is slidably connected in the sliding hole, the first screw rod 4 is threadedly connected with the first control wheel 5, and the first control wheel 5 is rotatably mounted on the top of the sampling rack 1. The first motor 6 is fixedly installed on the frame 1, the output shaft of the first motor 6 is fixedly connected with the second control wheel 7, the second control wheel 7 is engaged with the first control wheel 5, and the top of the moving plate 2 is provided with two Rotation hole, in two rotation holes, all rotation is installed with rotation bar 10, and the bottom end of tw...

Embodiment 2

[0032] refer to Figure 1-7 , a soil sampling device for highway engineering, comprising a sampling rack 1, the sampling rack 1 is provided with a moving plate 2, the top of the moving plate 2 is fixedly installed with a control box 3 by screws, and the top of the control box 3 is fixedly connected with a second A screw 4, the top of the sampling rack 1 is provided with a sliding hole, the first screw 4 is slidably connected in the sliding hole, the first screw 4 is threaded with a first control wheel 5, and the first control wheel 5 is rotatably mounted on the sampling rack 1 On the top of the sampling frame 1, a first motor 6 is fixedly installed by screws, and the output shaft of the first motor 6 is fixedly connected with a second control wheel 7 by screws, and the second control wheel 7 meshes with the first control wheel 5 to move The top of the plate 2 is provided with two rotating holes, and a rotating rod 10 is installed in the two rotating holes, and the bottom ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com