Power transmission line monitoring system of iron-steel combined enterprise

A technology for joint enterprises and transmission lines, applied in the direction of circuit devices, measuring electricity, measuring devices, etc., can solve problems such as joint insulation degradation, failure to be washed clean by rain, breakdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The invention provides a power transmission line monitoring system of an iron and steel complex, which is applied to the power transmission line of the iron and steel complex, and is used to effectively monitor potential safety hazards on the power transmission line.

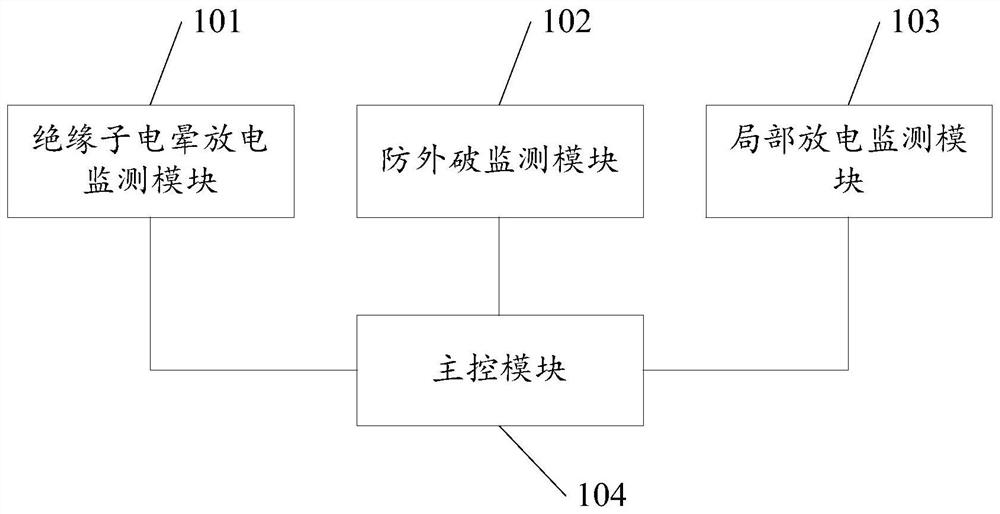

[0049] like figure 1 As shown, the system includes: an insulator corona discharge monitoring module 101 , an external breakage prevention monitoring module 102 , a partial discharge monitoring module 103 and a main control module 104 .

[0050] Wherein, the main control module 104 is respectively connected with the insulator corona discharge monitoring module 101 , the anti-breakage monitoring module 102 and the partial discharge monitoring module 103 .

[0051] The insulator corona discharge monitoring module 101 is set on the transmission line between two substations, and is used to collect corona traveling waves generated on the transmission line.

[0052]The anti-breakout monitoring module 102 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com