Machine for batch forming deep-fried dough cake bases

A raw embryo, batch technology, applied in dough forming machinery or equipment, application, dough sheeting machine/rolling machine/rolling pin, etc., can solve the problem of easy sticking to the machine, easy damage to the dough, and reduce dough pressing Efficiency and other issues, to achieve the effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

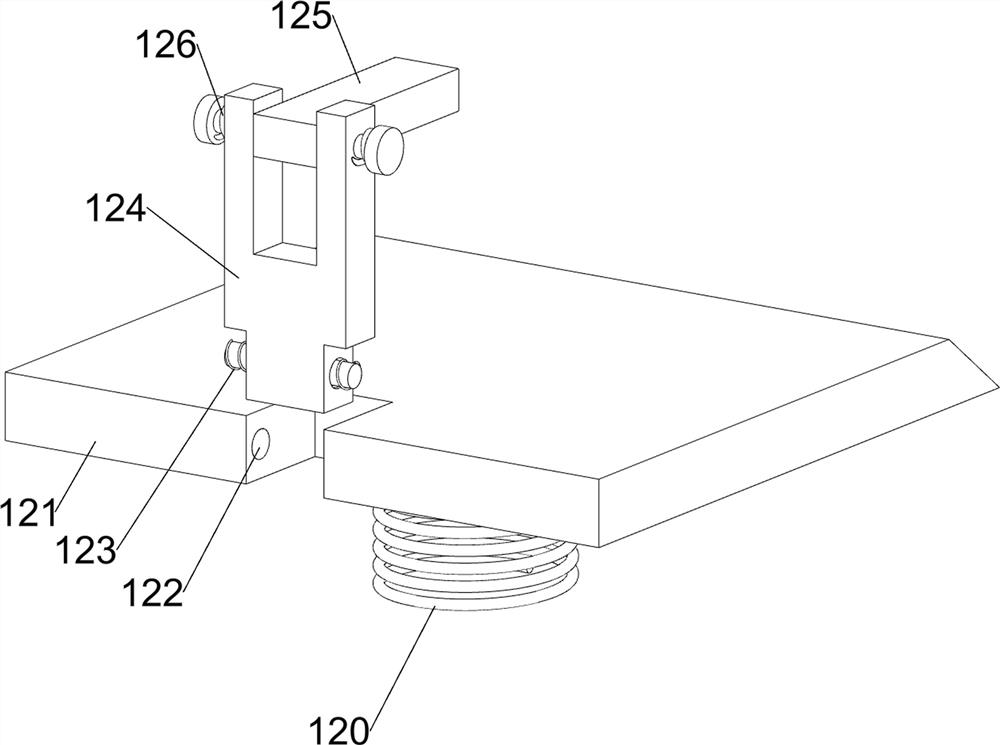

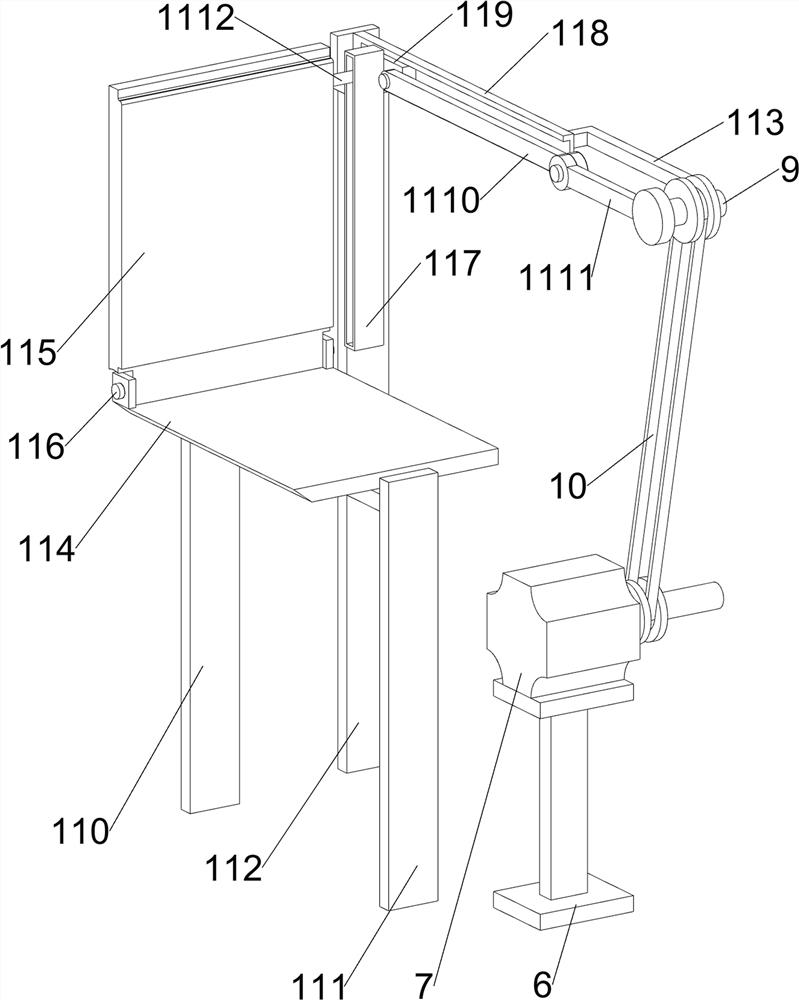

[0021] A machine for batch forming of green cakes, such as Figure 1-3 As shown, it includes a base 1, a first bearing seat 2, a first rotating shaft 3, a roller 4, a conveyor belt 5, a first support seat 6, a servo motor 7, a second bearing seat 8, a second rotating shaft 9, a transmission assembly 10, Bevel gear 101, pressing mechanism 11 and pushing mechanism 12, four first bearing seats 2 are evenly arranged on the upper part of base 1, and first rotating shafts 3 are arranged in the first bearing seats 2 on the left and right sides of the base 1, and the left and right sides Rollers 4 are provided on the first rotating shaft 3 of the motor, conveyor belts 5 are wound around the rollers 4 on the left and right sides, a first support seat 6 is provided on the right front side of the upper part of the base 1, and a servo motor 7 is provided on the first support seat 6. The servo The output shaft of the motor 7 and the front end of the first rotating shaft 3 on the right are ...

Embodiment 2

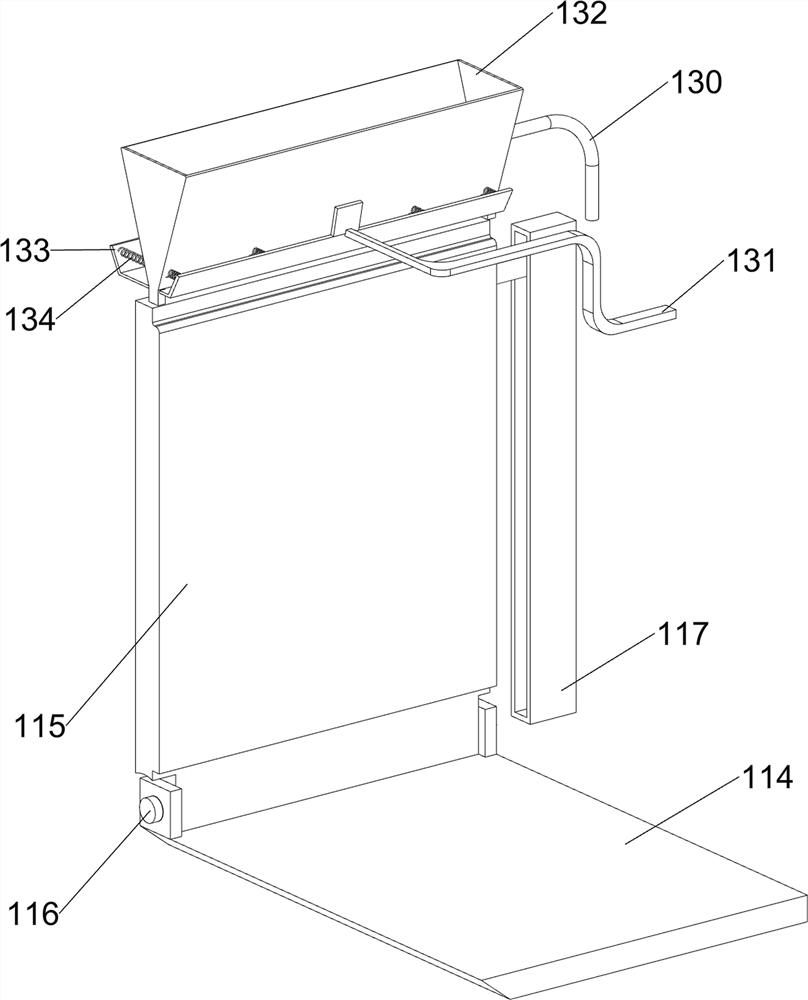

[0028] On the basis of Example 1, such as figure 1 and Figure 4 As shown, an oiling mechanism 13 is also included. The pressing mechanism 11 is provided with an oiling mechanism 13. The oiling mechanism 13 includes a fixed rod 130, a push rod 131, an oil storage tank 132, a sliding plate 133 and a second spring 134. Two slide rails 118 top rear sides are provided with fixed bar 130, and fixed bar 130 left parts are provided with oil storage tank 132, and oil storage tank 132 bottom sliding type is provided with slide plate 133, and oil storage tank 132 front and rear sides are respectively connected with slide plate 133 for how many times A second spring 134, a push rod 131 is provided on the left part of the first rotating rod 1110, and the rear end of the push rod 131 is located at the front side of the sliding plate 133.

[0029] In the process of pressing the dough, since the dough is thin, it is easy to damage the dough in the process of taking it. In order to facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com