A kind of tofu and preparation process thereof

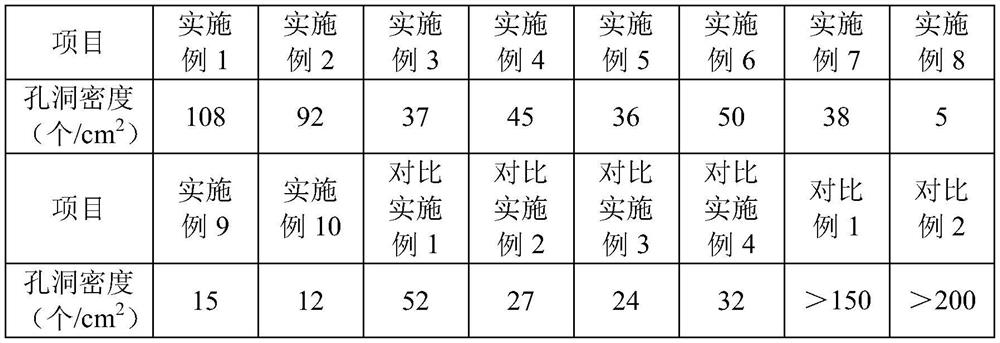

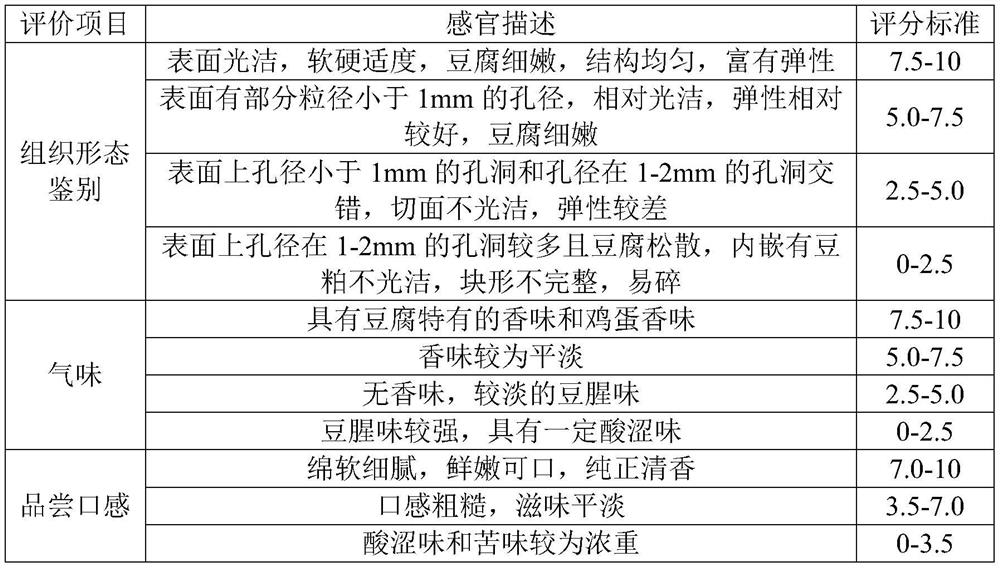

A preparation process and tofu technology, which are applied in the field of tofu and its preparation technology, can solve the problems of high pore density, loose tofu and bean quality, etc., and achieve the effects of tight and soft soybean quality, soft and delicate taste, and fresh and delicious soybean quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The application discloses a preparation process of tofu, comprising the following steps:

[0033] S1. Soak the peeled black beans in water, wherein the mass ratio of peeled black beans and water can be 1:(2.5-3), or 1:(3-3.5), for example, 1:2.75, 1: 3.25. In the process of soaking black beans, if the tofu preparation process is carried out at a relatively high indoor temperature, such as in summer (room temperature is higher than 25°C), the soaking time is 3-4.5h; if the tofu preparation process is carried out at a relatively high indoor temperature In the case of low temperature, such as winter (room temperature is lower than 25 ℃), the soaking time is 4.5-7h. When the black beans are soaked with water, when the black beans absorb all the water into the watercress, the next process step is performed.

[0034]S2. Refining: transfer the soaked bean paste into a refiner, and then grind it into a paste. In this refining process, the particle size of the soybean paste af...

Embodiment 1

[0048] A preparation process of tofu, the preparation of this tofu is carried out in summer, and specifically comprises the following steps: S1, 250kg of peeled black beans are placed in water to soak, wherein, the mass ratio of peeled black beans and water is 1:3. When soaking black beans, the room temperature is 29°C. After soaking for 4 hours, all the water added is absorbed into the watercress of black beans.

[0049] S2. Refining: Transfer the soaked watercress to the refiner, and set the speed of the refiner to 3000r / min. During refining, add pure water at all times to ensure the smooth progress of the refining process. Then collect the refined soybean paste, and the particle size of the soybean paste is less than or equal to 30 meshes.

[0050] S3, pulp washing: dilute the ground bean paste with water, and then filter the bean paste with a 300-mesh white silk cloth.

[0051] S4, boiling the milk: the soy milk in step S3 is placed in a steam pot and boiled for 5 minutes...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that in step S2 of this embodiment, the particle size of the obtained bean paste obtained by screening is ≤40 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com