Self-cleaning particulate matter purification device for chemical waste gas treatment

A purification device and exhaust gas treatment technology, which is applied in the direction of dispersed particle filtration, transportation and packaging, and separation of dispersed particles. It can solve the problems of filter structure blockage, large adhesion, and unfavorable exhaust gas filtration treatment, so as to slow down the impact force and avoid blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

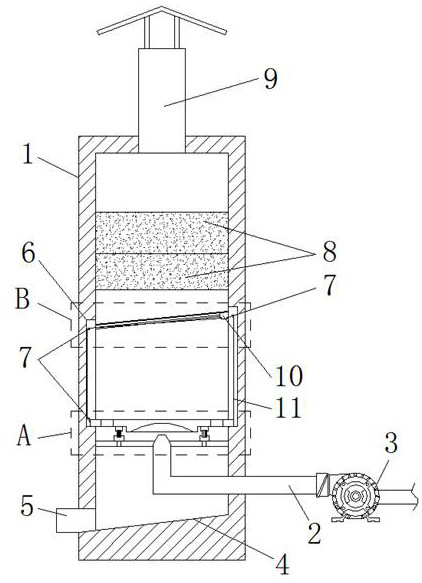

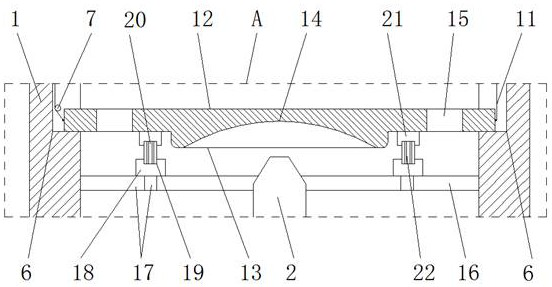

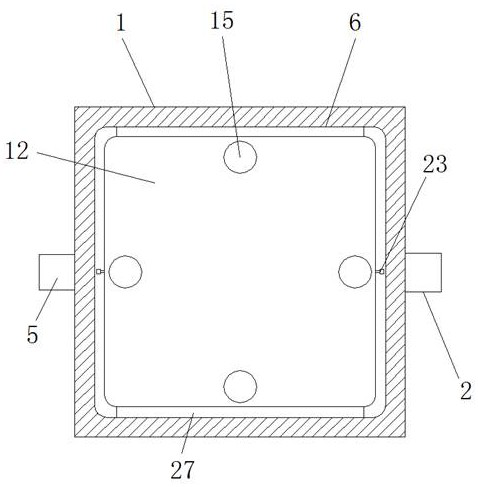

[0029] see Figure 1-8 , the present invention provides a technical solution: a self-cleaning particulate matter purification device for chemical waste gas treatment, including a purification device body (1, air intake pipe 2, fan 3, bottom tank 4, cleaning pipe 5, adjustment tank 6, fixed pulley 7. Purification structure 8, exhaust pipe 9, cleaning block 10, steel wire rope 11, counterweight plate 12, air floating part 13, air cavity 14, air vent 15, support frame 16, support ring 17, bottom fixed block 18, fixed Groove 19, rubber column 20, top fixing block 21, opening 22, connecting ring 23, screen plate 24, guide groove 25, hair brush 26 and slider 27, one end lower part of one side of purification device body 1 is provided with air intake pipe 2 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com