A photocatalytic reduction of co 2 reactor

A technology of CO2 and photocatalysis, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve problems such as inapplicability, and achieve the effect of efficient photocatalytic reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

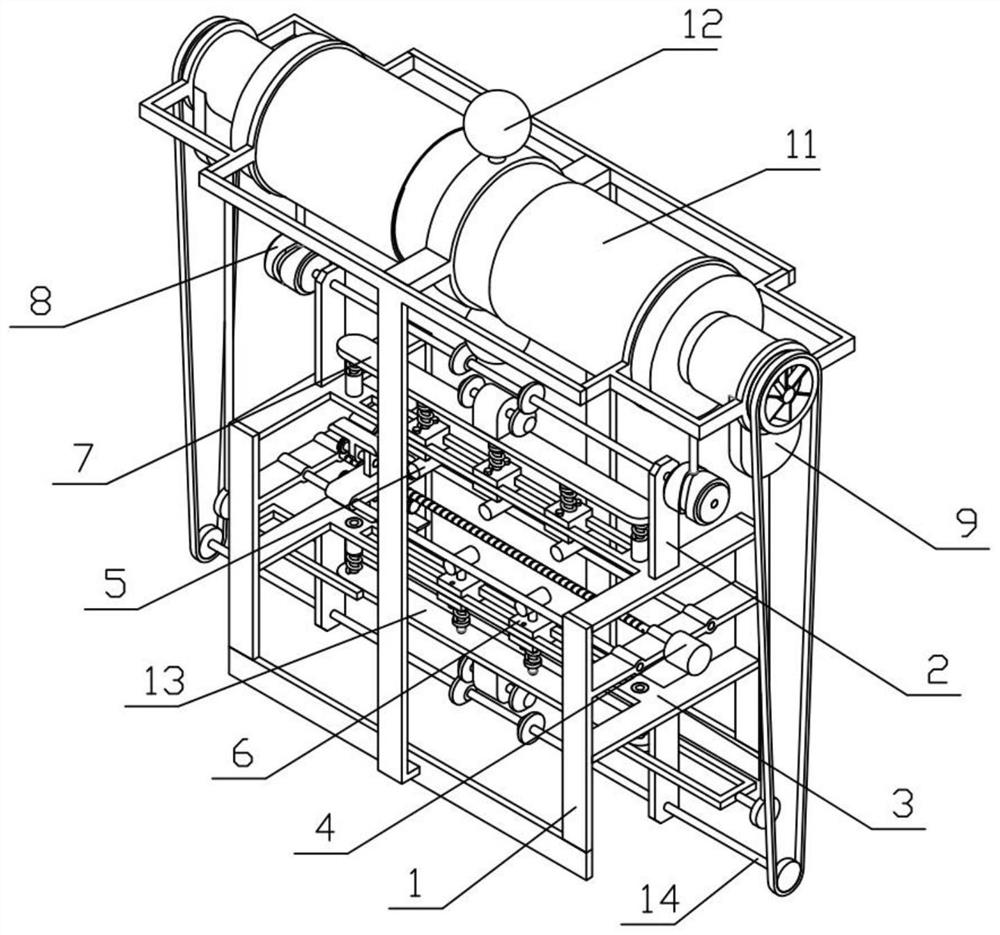

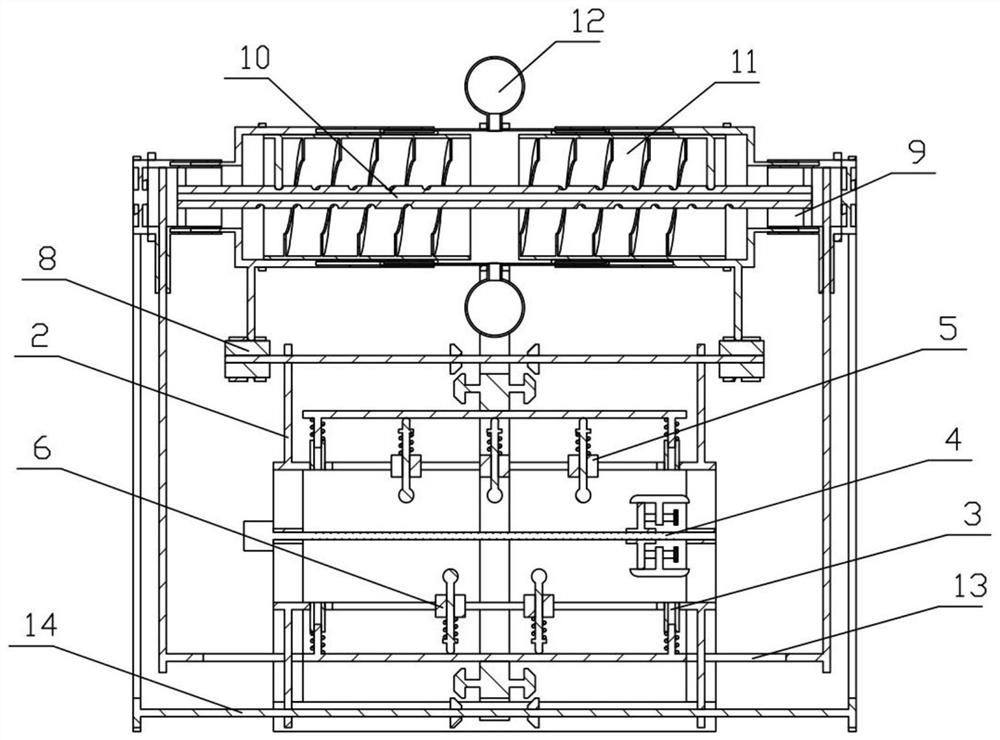

[0040] Combine below Figure 1-16 Describe this embodiment, a photocatalytic reduction of CO 2 Reactor, including device bracket 1, sliding bracket I2, sliding bracket II3, switching mechanism 4, pushing mechanism I5, pushing mechanism II6, pushing bracket I7, reciprocating mechanism 8, ventilation mechanism 9, ultraviolet lamp cover 10, oxidation mechanism I11, Oxidation mechanism II12, pushing bracket II13 and transmission mechanism 14, the device bracket 1 is fixedly connected with sliding bracket I2 and sliding bracket II3, the device bracket 1 is connected with switching mechanism 4, and switching mechanism 4 is located between sliding bracket I2 and sliding bracket II3 Among them, the sliding bracket I2 is connected with a plurality of pushing mechanisms I5, the sliding bracket II3 is connected with a plurality of pushing mechanisms II6, the sliding bracket I2 is slidingly connected with a pushing bracket I7, and the pushing bracket I7 is fixedly connected with the slidi...

specific Embodiment approach 2

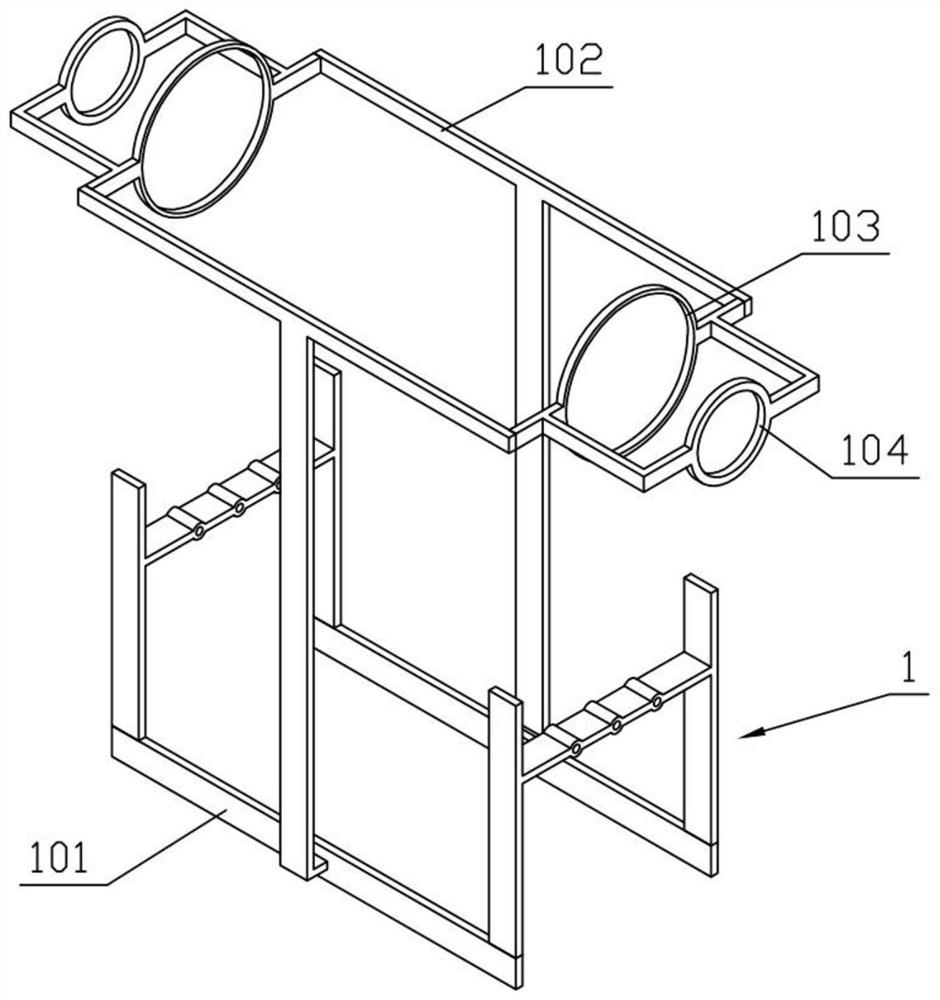

[0042] Combine below Figure 1-16 Describe this embodiment, this embodiment will further explain Embodiment 1, the device bracket 1 includes a bottom bracket 101, a top bracket 102, a connecting ring I 103 and a connecting ring II 104, the bottom bracket 101 is fixedly connected with a top bracket 102, and the top bracket The front and rear ends of 102 are fixedly connected with connecting ring I103, the two connecting rings I103 are fixedly connected with connecting ring II104, the sliding bracket I2 is provided with a long hole I201, the sliding bracket II3 is provided with a long hole II301, and the sliding bracket I2 and the sliding bracket II3 are fixedly connected to the bottom bracket 101 .

specific Embodiment approach 3

[0044] Combine below Figure 1-16 Describe this embodiment, this embodiment will further explain the second embodiment, the switching mechanism 4 includes a traverse motor 401, a limit column 402, a switch base plate 403, an adjustment screw 404 and a boat-shaped plate 405, and the traverse motor 401 is fixedly connected On the bottom bracket 101, the limit post 402 is fixedly connected on the bottom bracket 101, and the output shaft of the traverse motor 401 is connected with a switch base plate 403 by a thread, and the switch base plate 403 is slidably connected on the bottom bracket 101, and the up and down of the switch base plate 403 Both sides are rotatably connected with two adjusting screw rods 404 , and each adjusting screw rod 404 is threadedly connected with a ship-shaped plate 405 , and the four ship-shaped plates 405 are all slidably connected to the switch base plate 403 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com